Do you have a question about the Craftsman 113.213722 and is the answer not in the manual?

| Brand | Craftsman |

|---|---|

| Model | 113.213722 |

| Category | Power Tool |

| Language | English |

Understand your tool's capabilities and limitations for safe operation.

Always wear safety goggles to protect eyes from flying debris.

Ensure the workpiece is securely clamped to prevent movement during operation.

Ensure the switch is off before plugging in to prevent unexpected startup.

Read and understand the manual before operating the drill press.

Do not wear loose clothing, jewelry, or tie back long hair.

Familiarity breeds contempt; always be mindful of safety.

List of essential tools required for assembly and operation.

Inventory of all included parts for verification during unpacking.

Instructions for safely connecting the drill press to a grounded power outlet.

Guidelines for selecting and using extension cords to maintain power and safety.

Step-by-step guide for assembling the base and column.

Procedure for attaching the table support assembly.

Instructions for safely mounting the drill press head onto the column.

Guide for attaching the feed handles to the quill.

Steps for securely fitting the drill chuck onto the spindle.

Procedure for adjusting belt tension for optimal speed and performance.

How to ensure the drill press table is perpendicular to the head.

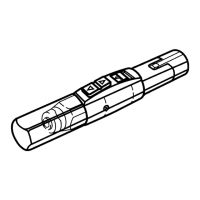

Diagram and identification of key spindle and assembly components.

Chart showing different spindle speed settings for various operations.

Understanding the switch operation and its locking feature for safety.

Instructions for safely removing and installing drill bits using the chuck.

Methods for setting and achieving precise drilling depths.

Guidance on properly positioning the table and workpiece for drilling.

Techniques for applying steady and controlled feed pressure.

Procedure for adjusting the quill return spring tension.

Recommended lubrication points and schedule for optimal performance.

Solutions for common problems like noisy operation, drill burns, and wobble.

Loading...

Loading...