assembly

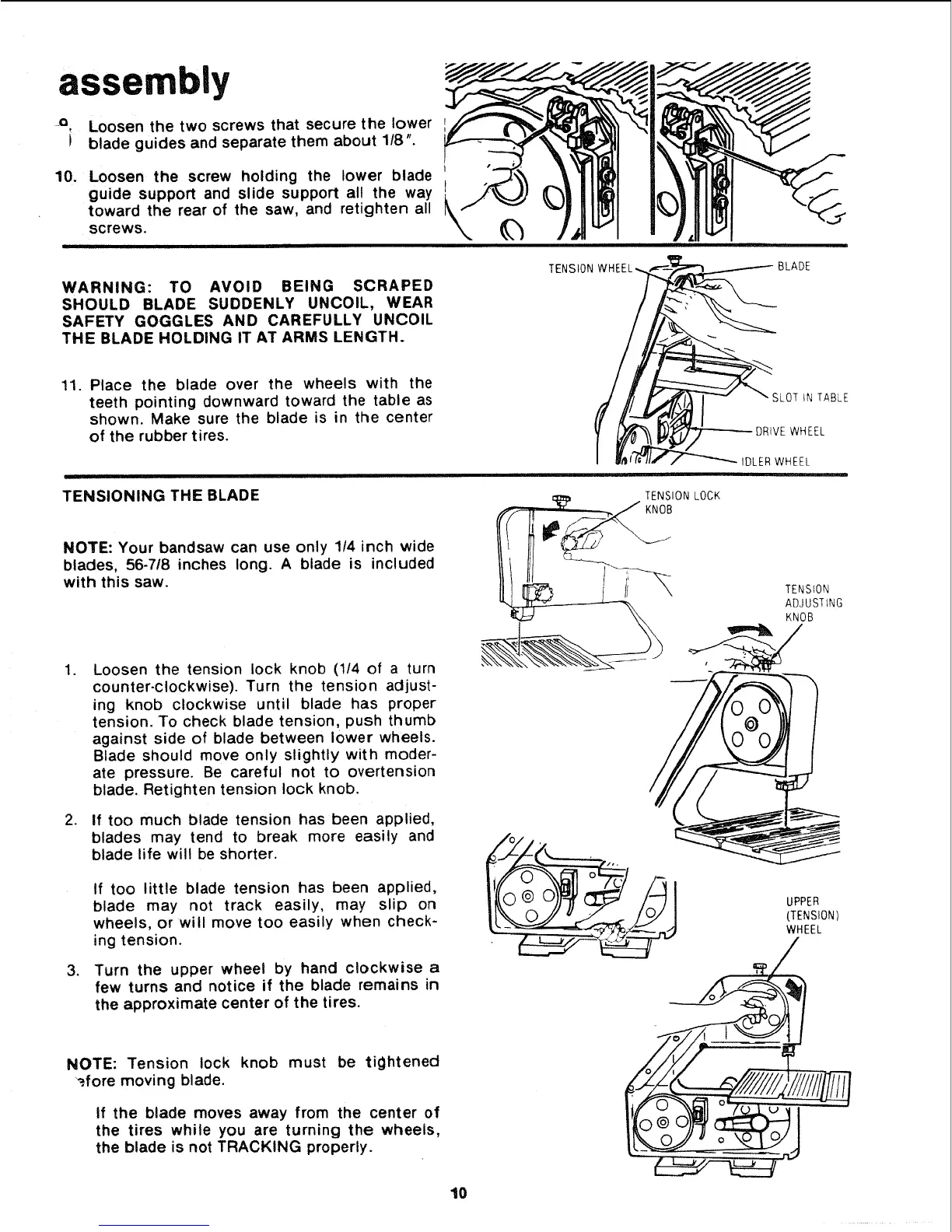

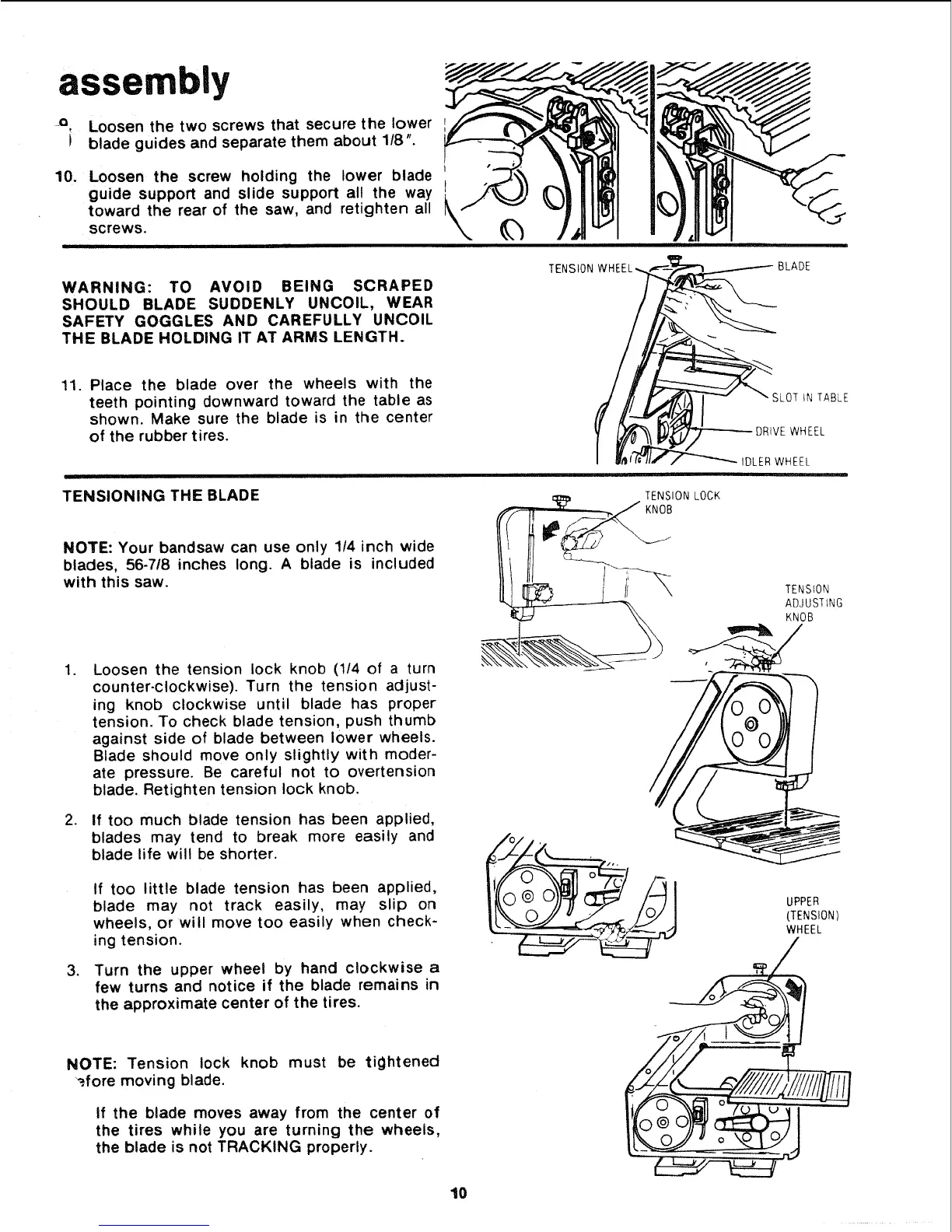

o Loosen the two screws that secure the lower

i blade guides and separate them about 1/8".

10. Loosen the screw holding the lower blade

guide support and slide support all the way L

toward the rear of the saw, and retighten all

\screws.

i

WARNING: TO AVOID BEING SCRAPED

SHOULD BLADE SUDDENLY UNCOIL, WEAR

SAFETY GOGGLES AND CAREFULLY UNCOIL

THE BLADE HOLDING IT AT ARMS LENGTH.

BLADE

11. Place the blade over the wheels with the

teeth pointing downward toward the table as

shown. Make sure the blade is in the center

of the rubber tires.

SLOT iN TABLE

)RIVE WHEEL

IDLER WHEEL

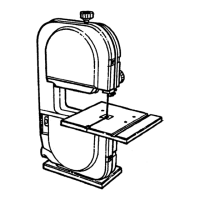

TENSIONING THE BLADE

TENSION LOCK

KNOB

NOTE: Your bandsaw can use only 114 inch wide

blades, 56-718 inches long. A blade is included

with this saw.

.

.

,

Loosen the tension lock knob (1/4 of a turn

counter-clockwise). Turn the tension adjust-

ing knob clockwise until blade has proper

tension. To check blade tension, push thumb

against side of blade between lower wheels.

Blade should move only slightly with moder-

ate pressure. Be careful not to overtension

blade. Retighten tension lock knob.

If too much blade tension has been applied,

blades may tend to break more easily and

blade life will be shorter.

If too little blade tension has been applied,

blade may not track easily, may slip on

wheels, or will move too easily when check-

ing tension.

Turn the upper wheel by hand clockwise a

few turns and notice if the blade remains in

the approximate center of the tires.

NOTE: Tension lock knob must be tightened

_.fore moving blade.

if the blade moves away from the center of

the tires while you are turning the wheels,

the blade is not TRACKING properly.

10

TENSION

ADJUSTING

KNOB

Loading...

Loading...