5 Piping installation

Installation manual

9

2MXM40+50A

R32 Split series

3P600450-5L – 2021.12

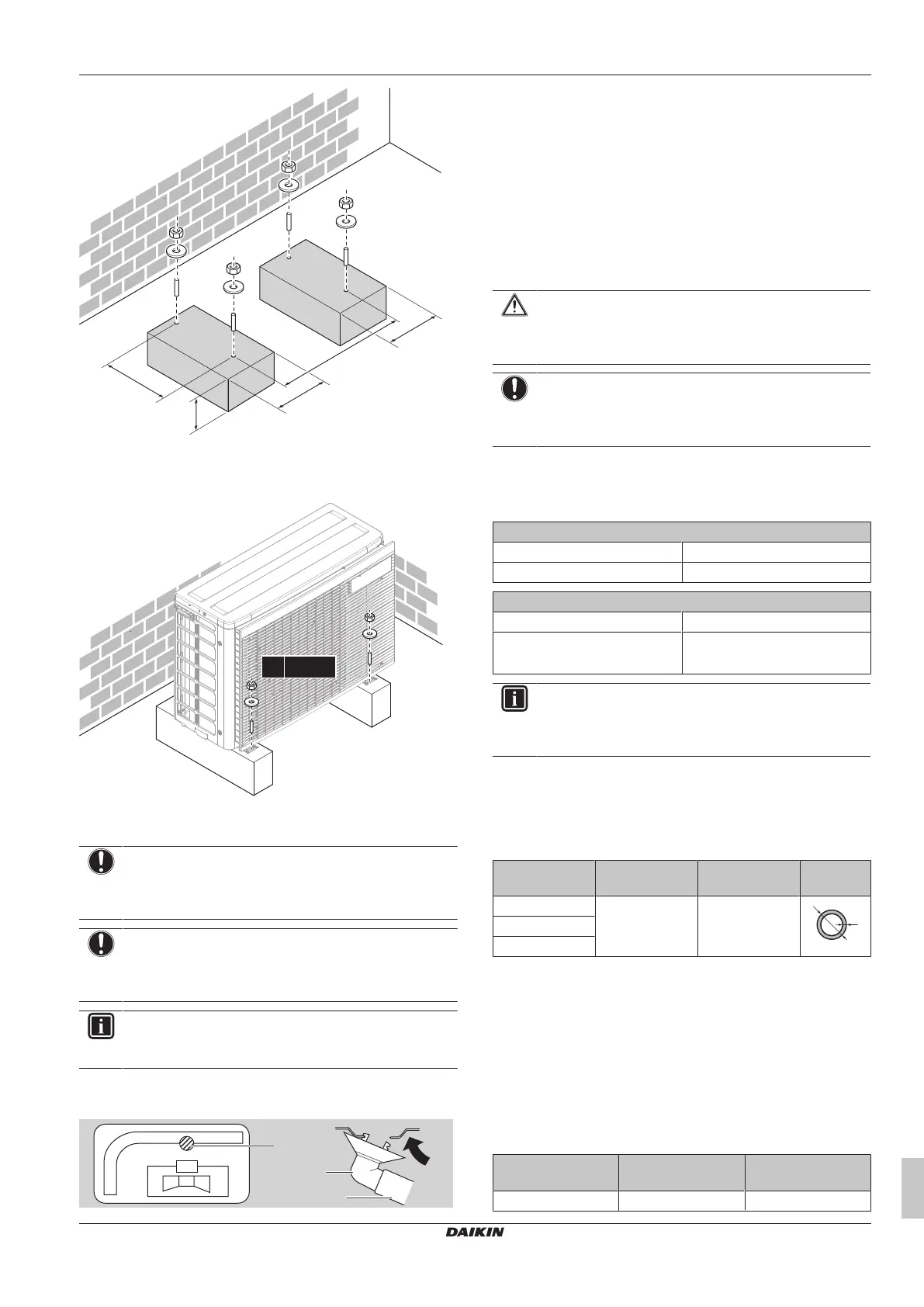

a 100mm above expected level of snow

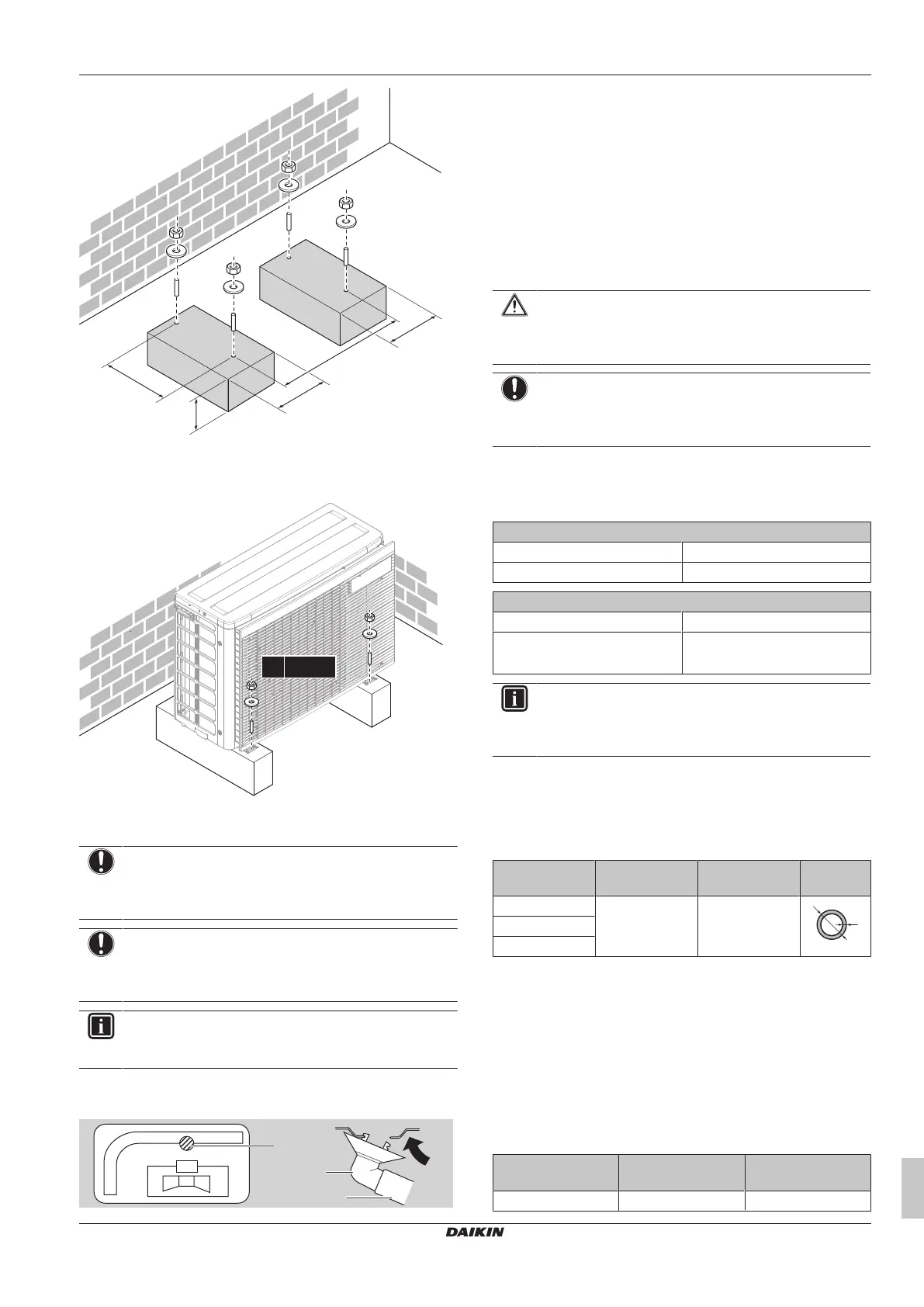

4.2.2 To install the outdoor unit

4.2.3 To provide drainage

NOTICE

If the unit is installed in a cold climate, take adequate

measures so that the evacuated condensate CANNOT

freeze.

NOTICE

If the drain holes of the outdoor unit are blocked up by a

mounting base or floor surface, place additional foot bases

≤30mm under the outdoor unit's feet.

INFORMATION

For information on the available options, contact your

dealer.

1 Use a drain plug for drainage.

2 Use a Ø16mm hose (field supply).

a Drain port

b Bottom frame

c Drain plug

d Hose (field supply)

5 Piping installation

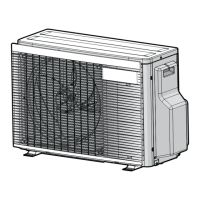

5.1 Preparing refrigerant piping

5.1.1 Refrigerant piping requirements

CAUTION

Piping and joints of a split system shall be made with

permanent joints when inside an occupied space except

joints directly connecting the piping to the indoor units.

NOTICE

The piping and other pressure-containing parts shall be

suitable for refrigerant. Use phosphoric acid deoxidised

seamless copper for refrigerant.

▪ Foreign materials inside pipes (including oils for fabrication) must

be ≤30mg/10m.

Refrigerant piping diameter

Class 40

Liquid piping 2× Ø6.4mm (1/4")

Gas piping 2× Ø9.5mm (3/8")

Class 50

Liquid piping 2× Ø6.4mm (1/4")

Gas piping 1× Ø9.5mm (3/8")

1× Ø12.7mm (1/2")

INFORMATION

Usage of reducers might be required based on the indoor

unit. See "5.2.1Connections between outdoor and indoor

unit using reducers"[410] for more information.

Refrigerant piping material

▪ Piping material: Phosphoric acid deoxidised seamless copper.

▪ Flare connections: Only use annealed material.

▪ Piping temper grade and thickness:

Outer diameter

(Ø)

Temper grade Thickness (t)

(a)

6.4mm (1/4") Annealed (O) ≥0.8mm

9.5mm (3/8")

12.7mm (1/2")

(a)

Depending on the applicable legislation and the maximum

working pressure of the unit (see "PS High" on the unit name

plate), larger piping thickness might be required.

5.1.2 Refrigerant piping insulation

▪ Use polyethylene foam as insulation material:

▪ with a heat transfer rate between 0.041 and 0.052W/mK (0.035

and 0.045kcal/mh°C)

▪ with a heat resistance of at least 120°C

▪ Insulation thickness

Pipe outer diameter

(Ø

p

)

Insulation inner

diameter (Ø

i

)

Insulation thickness

(t)

6.4mm (1/4") 8~10mm ≥10mm

Loading...

Loading...