12 English

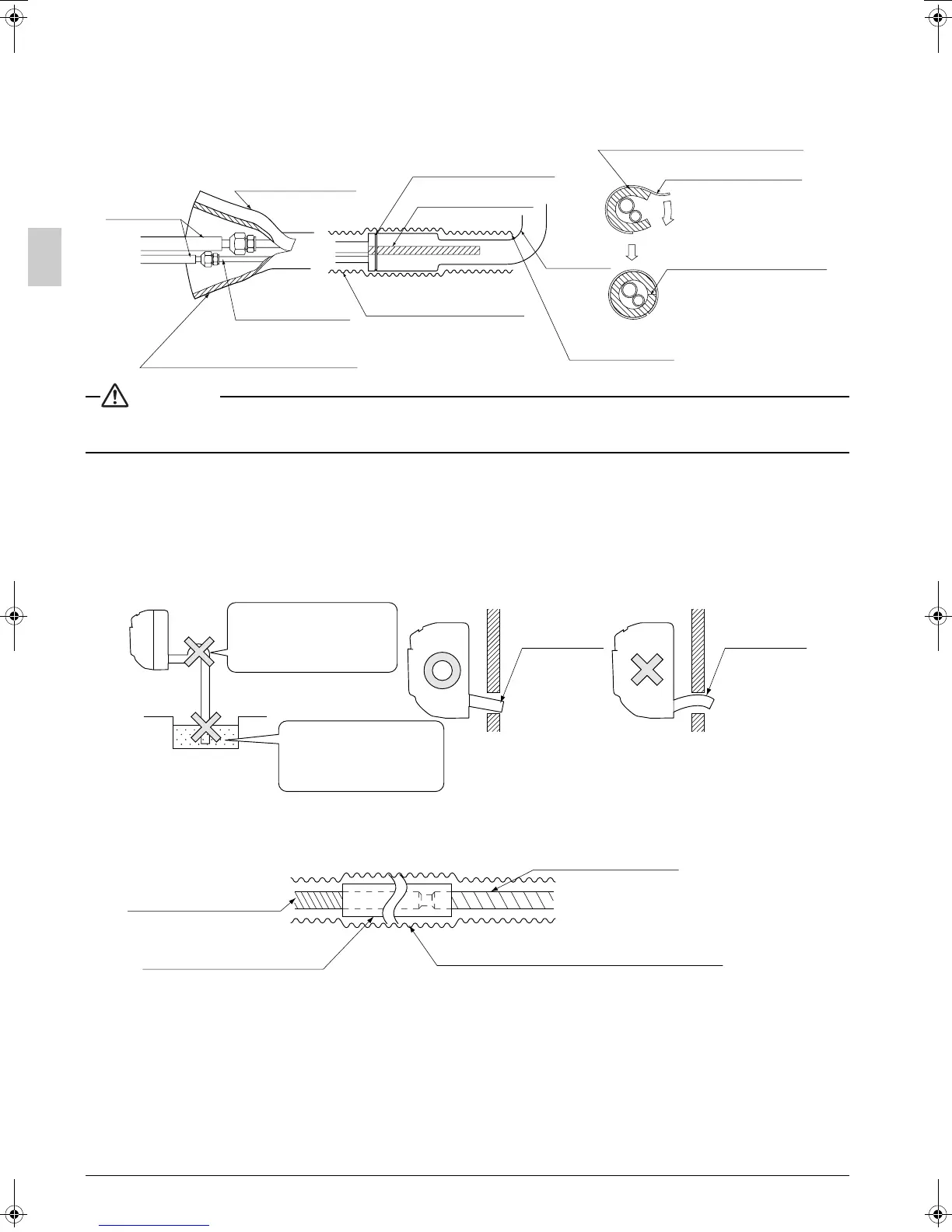

• After checking for gas leaks, be sure to insulate the pipe connections using the supplementary piping

insulation tubing and insulating tape (4). The insulating tape (4) should be wrapped from the L-shaped bend

all the way to the end inside the unit. (Refer to Fig. 15)

CAUTION

Be sure to insulate any field piping all the way to the piping connection inside the unit. Any exposed piping

may cause condensation or burns if touched.

6. DRAIN PIPING WORK

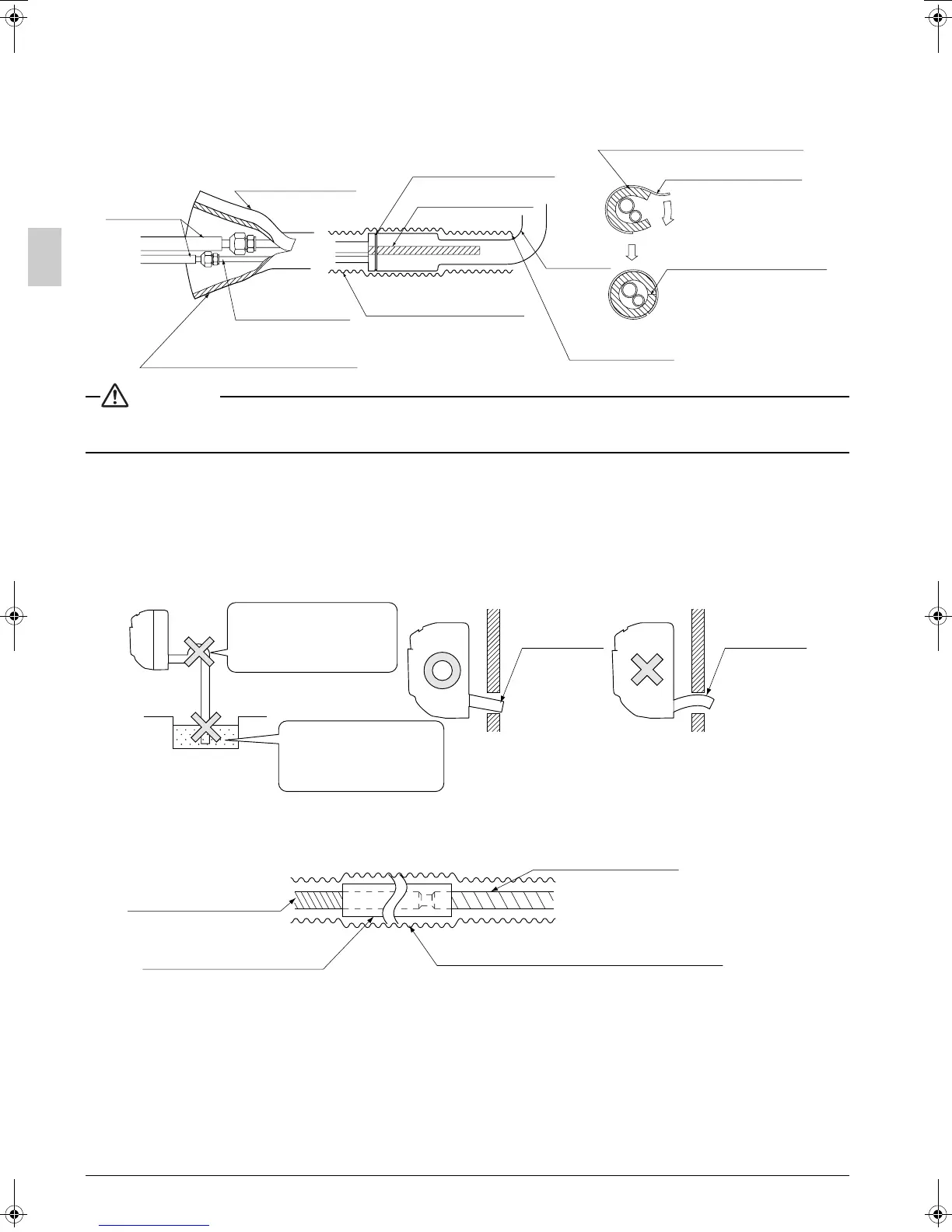

(1) Install the drain piping. (Refer to Fig. 16)

• The drain pipe should be short with a downward slope and should prevent air pockets from forming.

• Watch out for the points in the Fig. 16 when performing drain work.

• When extending the drain hose, use a commercially available drain extension hose, and be sure to

insulate the extended section of the drain hose which is indoors. (Refer to Fig. 17)

• Make sure the diameter of the piping is the same as the piping (hard vinyl chloride, nominal diameter

13mm) or bigger.

Insulating tubing tape

Insulating tubing tape

Local piping

Indoor unit piping

Indoor unit piping insulation tubing

Clamping material large

(accessory) (5)

Insulating tape (accessory) (4)

L-shaped

bend

Start wrapping

See “4. INDOOR UNIT

INSTALLATION”

Indoor unit piping insulation tubing

Insulating tubing tape

Insulation tubing seam

Attach the insulation tubing

tape so that there are no gaps

in the insulation tubing seam.

Fig. 15

Fig. 16

Make sure the drain

hose is at a downward

slope.

Make sure the tip does

not go underwater even

when water is added.

Drain hose Drain hose

(Downward

slope)

Indoor unit drain hose

Extension drain piping

(commercially available)

Insulating tube

(commercially available)

Insulating tape (accessory) (4)

( See “4. INDOOR UNIT INSTALLATION” )

Fig. 17

01_EN_3P366851-14C.fm Page 12 Wednesday, October 14, 2015 3:02 PM

Loading...

Loading...