4 Installation

Installation manual

7

(A)RXP20~35L5V1B + RXF20~35A5V1B + RXF20~25B5V1B

R32 split series

3P519299-2H – 2019.09

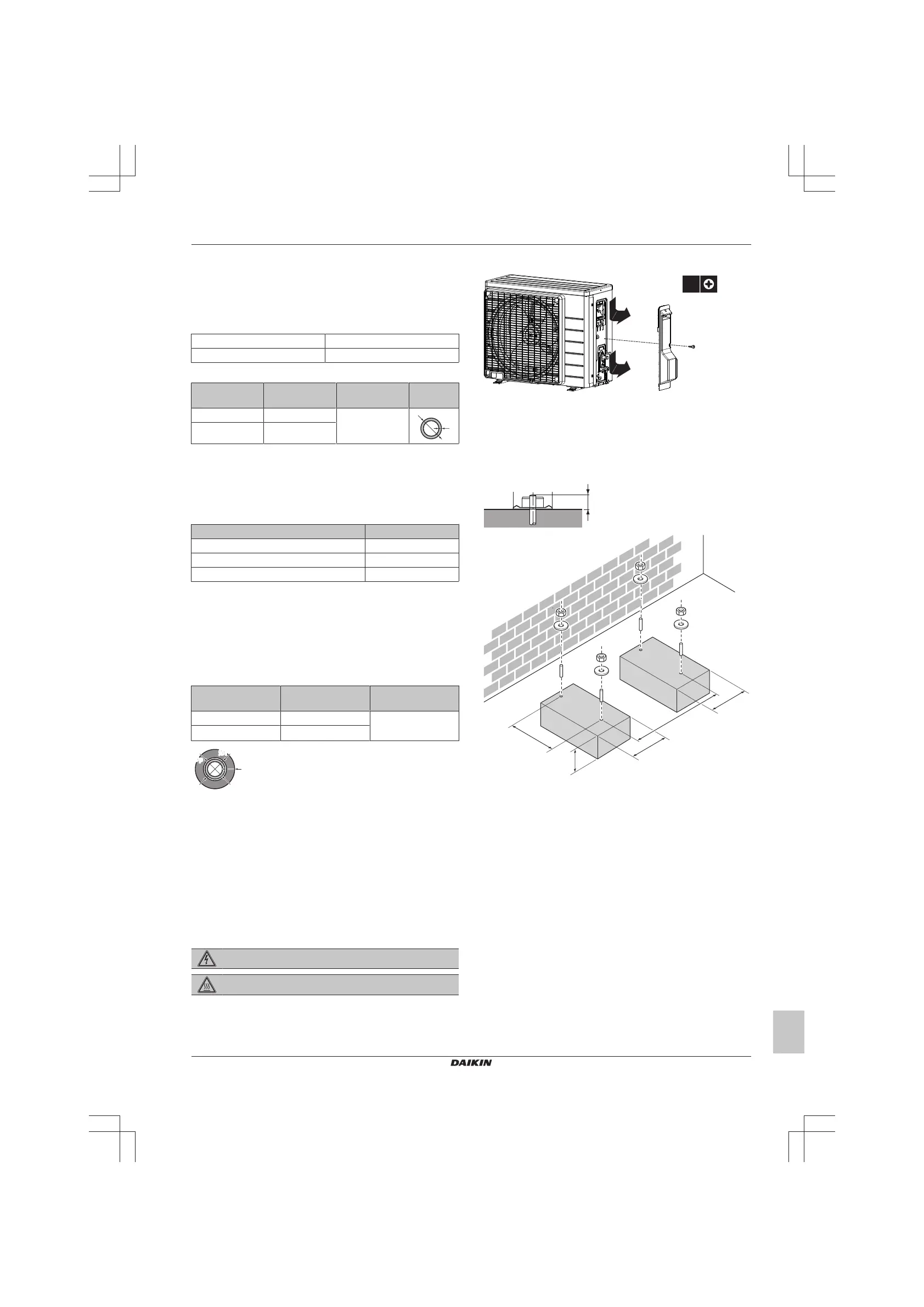

3.2 Preparing refrigerant piping

3.2.1 Refrigerant piping requirements

▪ Piping material: Phosphoric acid deoxidised seamless copper.

▪ Piping diameter:

Liquid piping Ø6.4mm (1/4")

Gas piping Ø9.5mm (3/8")

▪ Piping temper grade and thickness:

Outer diameter

(Ø)

Temper grade Thickness (t)

(a)

6.4mm (1/4") Annealed (O) ≥0.8mm

9.5mm (3/8") Annealed (O)

(a)

Depending on the applicable legislation and the unit's

maximum working pressure (see "PS High" on the unit

name plate), larger piping thickness might be required.

3.2.2 Refrigerant piping length and height

difference

What? Distance

Maximum allowable pipe length 15m

Minimum allowable pipe length 1.5m

Maximum allowable height difference 12m

3.2.3 Refrigerant piping insulation

▪ Use polyethylene foam as insulation material:

▪ with a heat transfer rate between 0.041 and 0.052W/mK (0.035

and 0.045kcal/mh°C)

▪ with a heat resistance of at least 120°C

▪ Insulation thickness

Pipe outer diameter

(Ø

p

)

Insulation inner

diameter (Ø

i

)

Insulation thickness

(t)

6.4mm (1/4") 8~10mm ≥10mm

9.5mm (3/8") 12~15mm

If the temperature is higher than 30°C and the humidity is higher

than RH80%, the thickness of the insulation materials should be at

least 20 mm to prevent condensation on the surface of the

insulation.

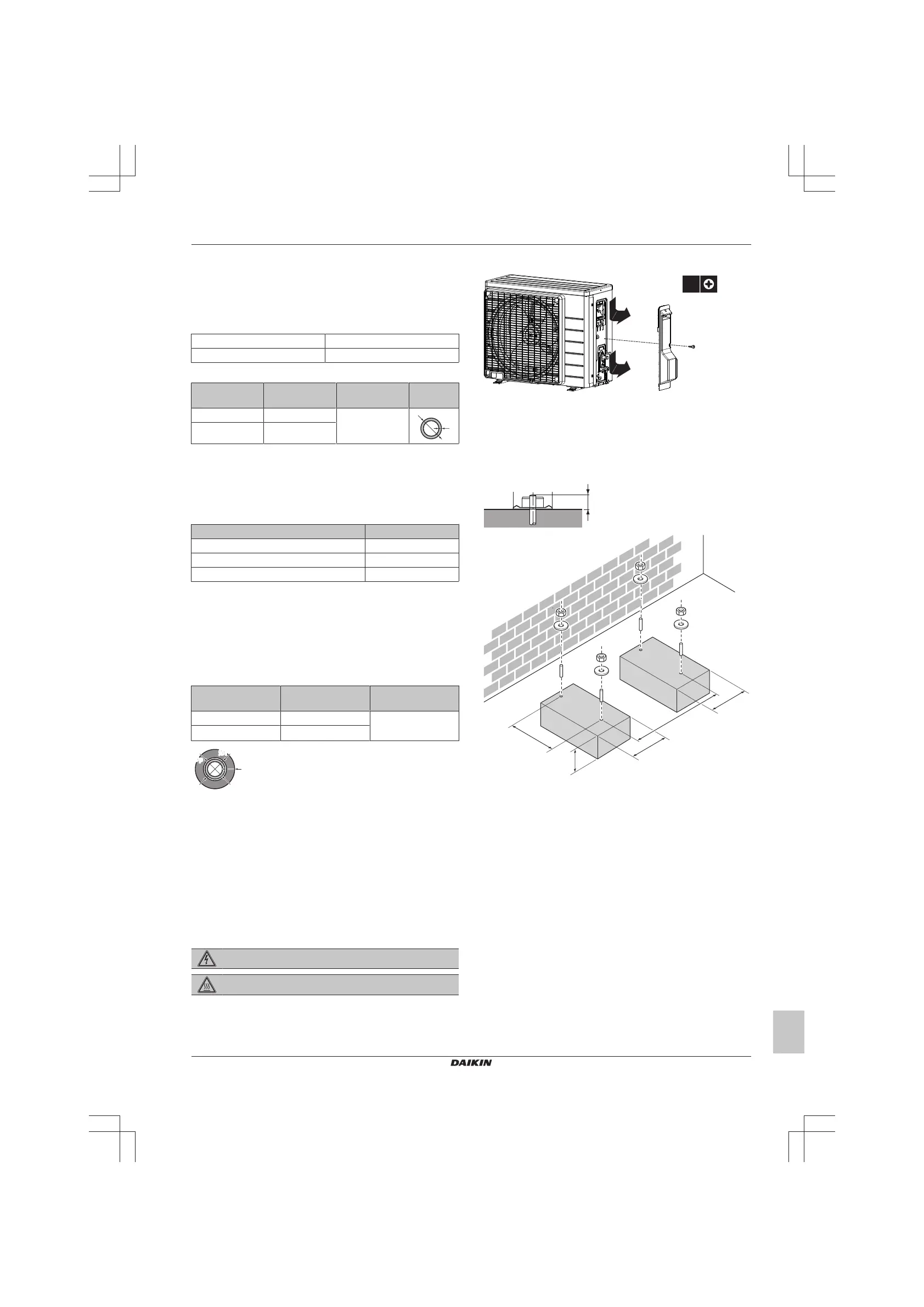

4 Installation

4.1 Opening the units

4.1.1 To open the outdoor unit

DANGER: RISK OF ELECTROCUTION

DANGER: RISK OF BURNING

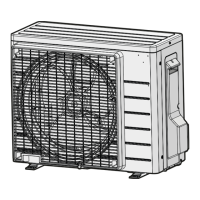

4.2 Mounting the outdoor unit

4.2.1 To provide the installation structure

Prepare 4 sets of M8 or M10 anchor bolts, nuts and washers (field

supply).

In heavy snowfall areas, it is recommended to provide at least

300 mm of free space below the unit. For other areas, it is

recommended to provide at least 150 mm of free space below the

unit.

In any case, make sure the unit is positioned at least 100mm above

the maximum expected level of snow. If necessary, construct a

pedestal.

Loading...

Loading...