3. Inspect the spindle for wear.

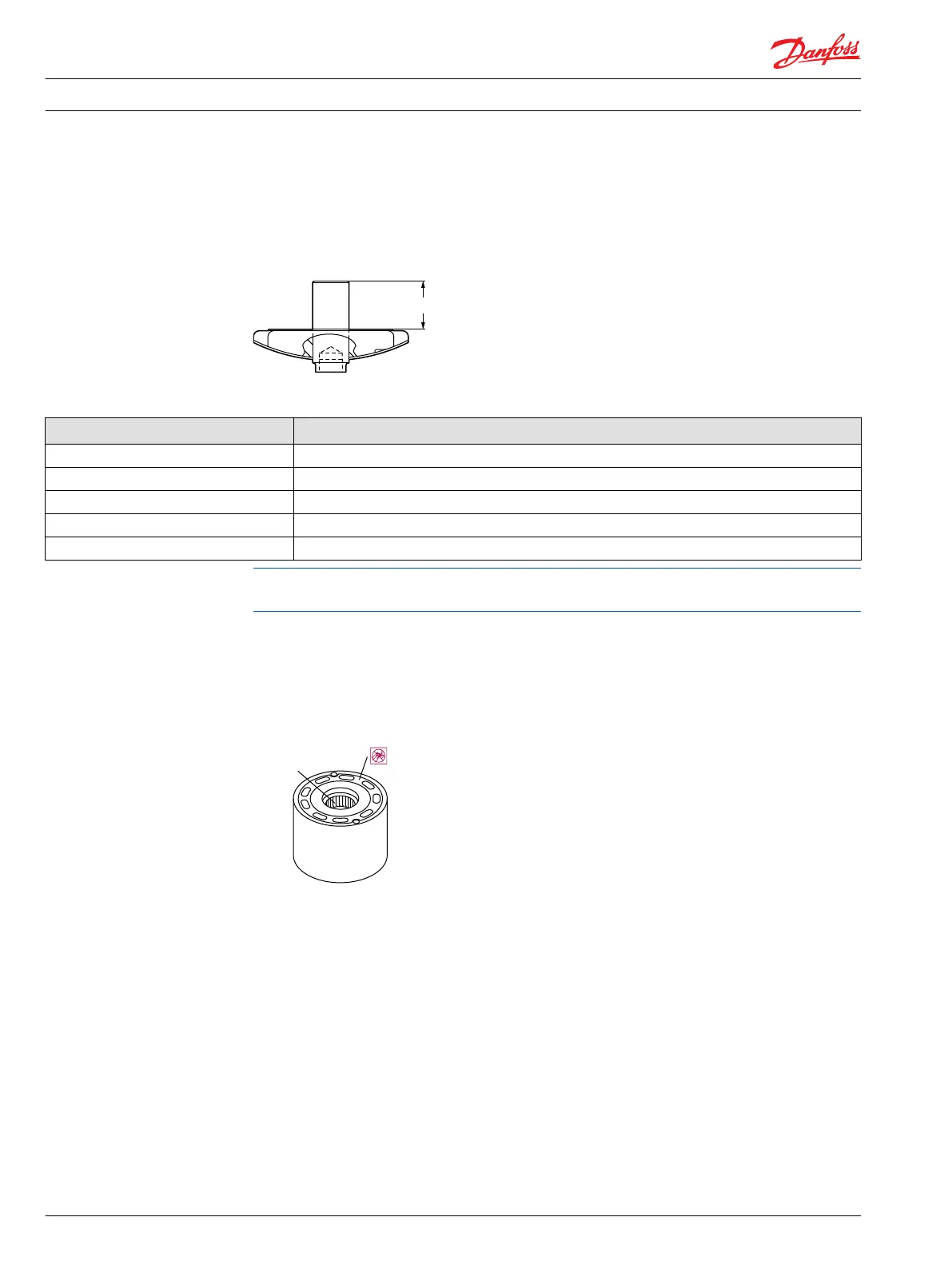

4. Ensure the spindle is located correctly in the valve segment by measuring distance A. If this

dimension is not within the range shown in the table, it indicates that the spindle has moved in the

valve segment. Replace it.

Valve segment

Spindle location distance

Frame size Distance A mm [in]

060 27.5 ± .4 [1.08 ± 0.02]

080 32 ± .4 [1.25 ± 0.02]

110 34 ± .4 [1.34 ± 0.02]

160 38.9 ± .4 [1.49 ± 0.02]

250 44.2 ± .4 [1.74 ± 0.02]

Do not lap the valve segment to remove scratches. The hard treated surface is thin and lapping may

remove this surface. Removing the spindle loosens its tight press fit and allows it to move.

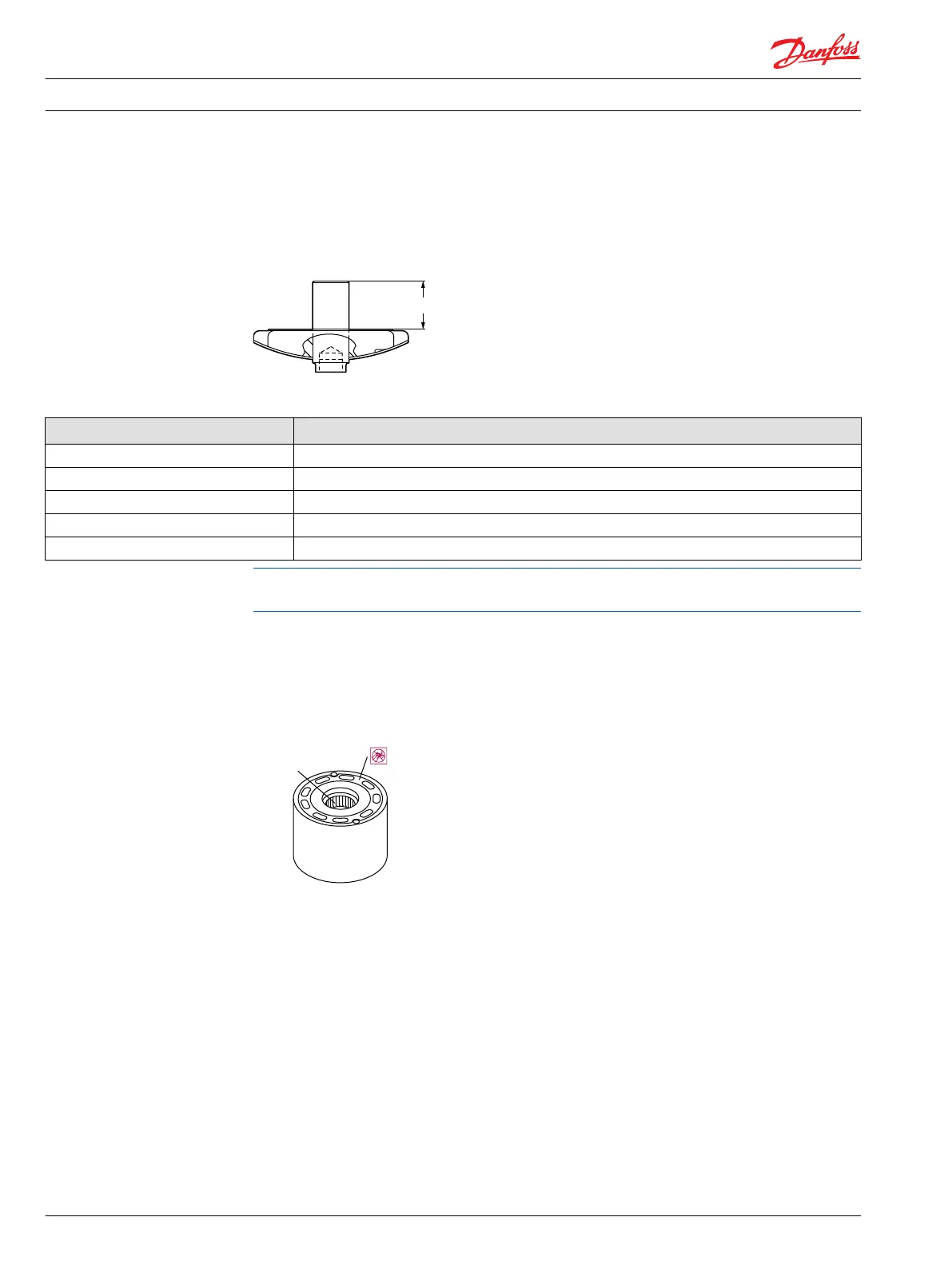

5. Inspect cylinder block assembly for wear or damage. If bearing is worn or damaged, replace the

complete block assembly. The bearing is not available as a separate part.

The piston bores must be smooth. The bearing plate surface must be free from scratches or nicks. The

holes for the bearing plate locating pins must be free from wear. The races for the synchronizing shaft

rollers must also be free from wear.

Cylinder block bearing

Repair Instructions

Series 51 and 51-1 Bent Axis Motors Repair Instructions

Inspection

18 11009449 • Rev BA • December 2014

Loading...

Loading...