transistors are "turned off"), which means that the mo-

tor runs freely to stop. Logic '0' leads to coasting to

stop.

Reset and coasting inverse are used to activate motor

coast simultaneously with reset. Logical '0' means mo-

tor coast stop and reset. Reset is activated on the

falling edge.

Quick stop inverse is used for activating the quick-stop

ramp down set in parameter 212 Quick stop ramp-

down time. Logic '0' leads to quick stop.

DC-braking inverse is used for stopping the motor by

energizing it with a DC voltage for a given time, see

parameters 126, 127 and 132 DC brake. Please note

that this function is only active if the value in parameter

126 DC braking time and 132 DC brake voltage is dif-

ferent from 0. Logic '0' leads to DC braking.

Stop inverse, a logic '0' means that the motor speed is

ramped down to stop via the selected ramp.

None of the stop commands mentioned

above are to be used as repair switches.

Note that the frequency converter has

more voltage inputs than L1, L2 and L3

when the DC bus terminals are used.

Check that all voltage inputs are discon-

nected and that the prescribed time (4

mins.) has passed before repair work is

commenced.

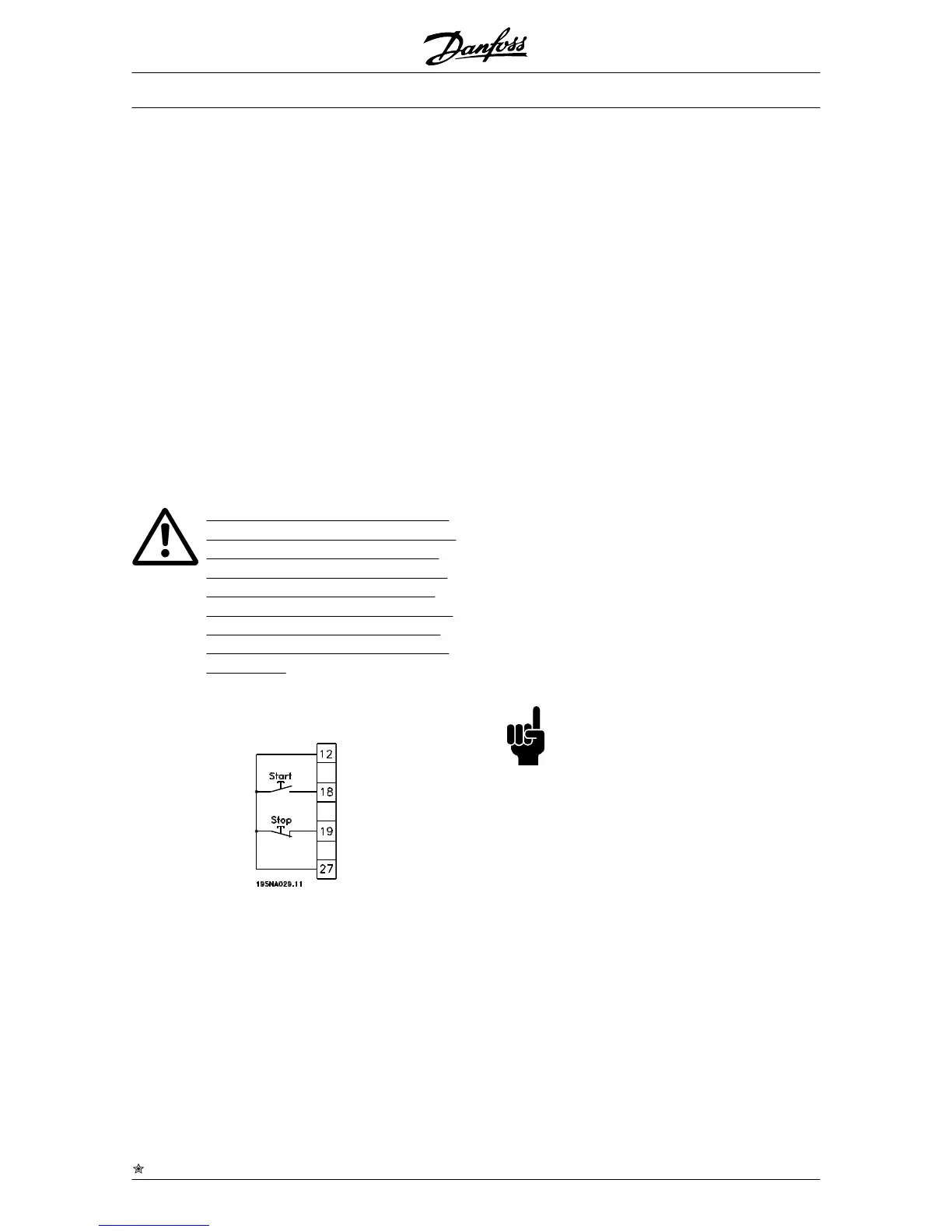

Start is selected if a start/stop command is required.

Logic '1' = start, logic '0' = stop.

Latched start, if a pulse is applied for min. 14 ms, the

frequency converter will start the motor, provided no

stop command has been given. The motor can be

stopped by briefly activating Stop inverse.

Reversing is used for changing the direction of rotation

of the motor shaft. Logic '0' will not lead to reversing.

Logic '1' will lead to reversing. The reverse signal only

changes the direction of rotation, it does not activate

the start. Is not active at Process regulation, closed

loop . See also parameter 200 Output frequency range/

direction.

Reversing and start is used for start/stop and for re-

versing with the same signal. No active start command

is allowed at the same time. Acts as latch start revers-

ing, provided latch start has been chosen for terminal

18. Is not active for Process regulation, closed loop.

See also parameter 200 Output frequency range/di-

rection.

Start clockwise is used if you want the motor shaft only

to be able to rotate clockwise when started. Should not

be used for Process regulation, closed loop.

Start anticlockwise is used if you want the motor shaft

only to be able to rotate anticlockwise when started.

Should not be used for Process regulation, closed

loop. See also parameter 200 Output frequency range/

direction.

Jog is used to override the output frequency to the jog

frequency set in parameter 213 Jog frequency. Jog is

active regardless of whether a start command has

been given, yet not when Coast stop, Quick-stop or

DC braking are active.

Freeze reference freezes the present reference. The

reference can now only be changed via Speed up and

Speed down. If freeze reference is active, it will be

saved after a stop command and in the event of mains

failure.

Freeze output freezes the present output frequency (in

Hz). The output frequency can now only be changed

via Speed up and Speed down .

NB!

If Freeze output is active the frequency

converter can only be stopped if you se-

lect Motor coast, Quick stop or DC brak-

ing via a digital input.

Speed up and Speed down are selected if digital con-

trol of the up/down speed is required. This function is

only active if Freeze reference or Freeze output frequen-

cy has been selected.

If Speed up is active the reference or output frequency

will be increased, and if Speed down is active the ref-

erence or output frequency will be reduced. The output

frequency is changed via the preset ramp times in pa-

rameters 209-210 Ramp 2.

One pulse (logic '1' minimum high for 14 ms and a

minimum break time of 14 ms) will lead to a speed

change of 0.1 % (reference) or 0.1 Hz (output frequen-

cy). Example:

VLT

®

2800 Series

= factory setting, () = display text, [] = value for use in communication via serial communication port

36 MG.27.A2.02 - VLT

®

is a registered Danfoss trademark

Loading...

Loading...