VLT

®

5000 Series

Programming

300 Terminal 16, input

(DIGITAL INPUT 16)

Function:

In this and the following parameters it is possible

to choose between the different possible functions

related to the inputs on terminals 16-33.

The function options are shown in the table on page

111. The maximum frequency for terminal 16, 17,

18 and 19 is 5 kHz. The maximum frequency for

terminals 29, 32 and 33 is 65 kHz.

Description of choice:

No function is selected if the frequency converter is

not to react to signals transmitted to the terminal.

Reset zeroes the frequency converter after an alarm;

however, not all alarms can be reset.

Coasting stop inverse is used for making the

frequency converter let go of the motor to make it coast

freely to stop. Logic ’0’ leads to coasting stop and reset.

Reset and coasting stop inverse,isusedfor

activating coasting stop at the same time as reset.

Logic ‘0’ leadstocoastingstopandreset

Quick-stop inverse is used for stopping the motor in

accordance with the quick-stop ramp (set in parameter

212). Logic ’0’ leads to a quick-stop.

DC braking inverse is used for stopping the

motor by energizing it with a DC voltage for a

given time, see parameters 125-127.

Please note that this function is only active if the

value of parameters 126-127 is different from 0.

Logic ’0’ leadstoDCbraking.

Stop inverse is activated by interrupting the voltage

to the terminal. This means that if the termin

al

has no voltage, the motor cannot run. The stop

will be effected in accordance with the selected

ramp (parameters 207/208/209/210).

None of the above-mentioned stop

commands (start-disable) are to be used

as disconnection switch in connection

with repairs. Cut mains instead.

NB!:

It must be noted that when the frequency

converter is at the torque limit and has received

a stop command, it will only

stop if terminal

42, 45, 01 or 04 has been connected to terminal

27. The data choice on terminal 42, 45, 01 or 04

must be Torque limit and s

top [27].

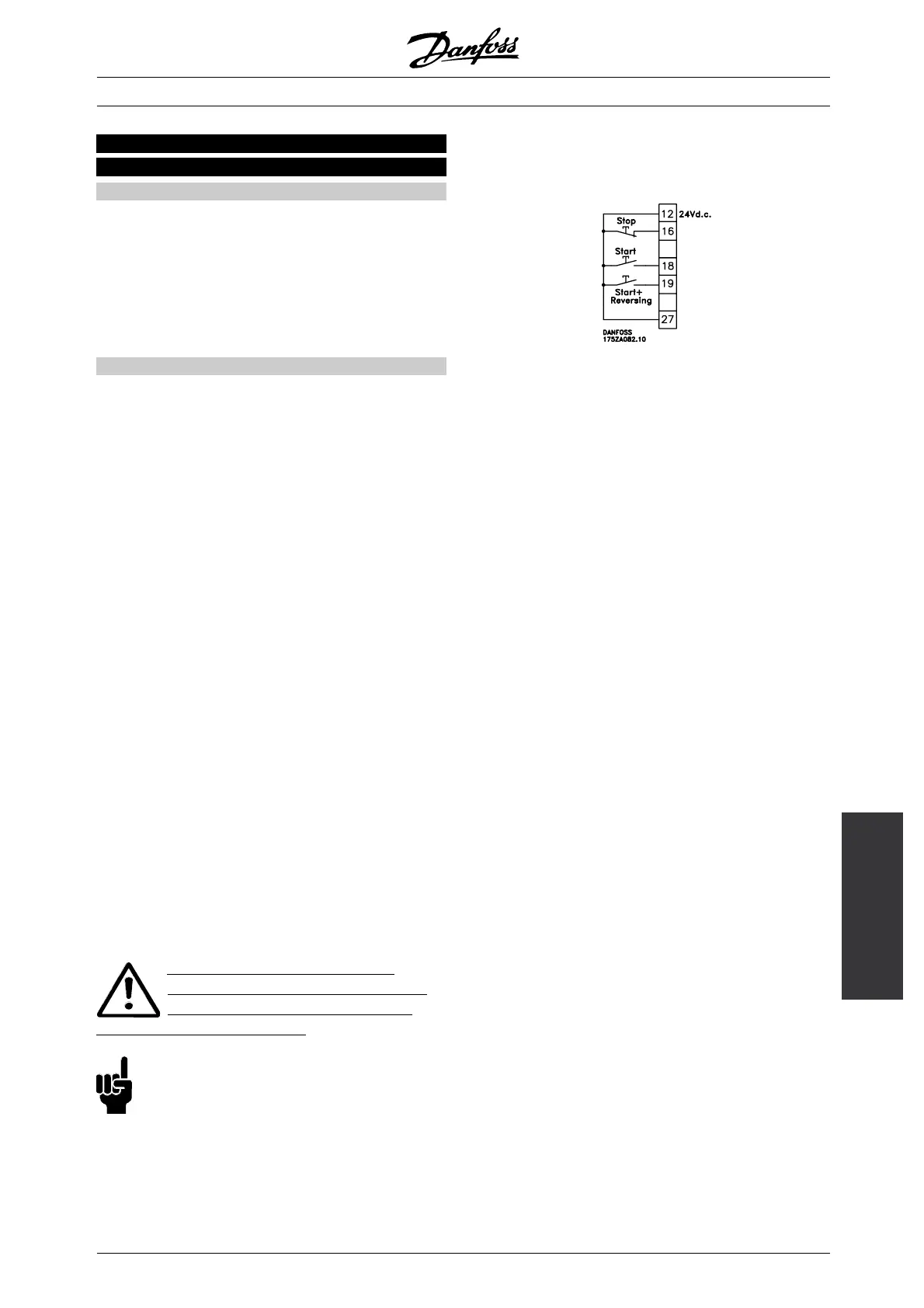

Start, is selected if a start/stop (operating

command, group 2) command is desired. Logic

’1’ = start, logic ’0’ =stop.

Latched start - if a pulse is applied for min. 3 ms,

the motor will start, provided no stop command

(operating command, group 2). The motor stops

if Stop inverse is activated briefly.

Reversing is used for changing the direction of

rotation of the motor shaft. Logic "0" will not lead

to reversing. Logic "1" will lead to reversing. The

reversing signal only changes the direction of rotation;

it does not activate the start function.

Reversing requires that Both directions has been

selected in parameter 200.

Is not active if Process control, closed loop,

Torque control open loop or Torque control, speed

feedback has been selected.

Start reversing, is used for start/stop (operating

command, group 2) and for reversing with the same

signal. No signal is allowed on terminal 18 at the

same time. Acts as latch start reversing, provided

latchstarthasbeenchosenforterminal18.

Is not active if Process control, closed loop

has been selected.

Start clockwise only, on is used if the motor shaft is

only to be able to rotate clockwise when starting.

Should not be used with Process control, closed loop.

Start anti-clockwise only , is used if the motor shaft

is to rotate anti-clockwise when started.

Should not be used with Process control, closed loop.

Jog is used for overriding the output frequency to the

jog frequency set in parameter 213. The ramp time

can be set in parameter 211. Jog is not active if a

stop command has been given (start-disable). Jog

overrides stop (operating command, group 2).

Preset reference, on is used for shifting between

external reference and preset reference. It is assumed

that External/preset [2] has been selected in parameter

214. Logic ’0’ = external references active; logic

’1’ = one of the four preset references is active

in accordance with the table below.

✭

= factory setting. () = display text [] = value for use in communication via serial communication port

MG.51.A9.02 - VLT is a registered Danfoss trademark

123

Loading...

Loading...