VLT

®

5000 Series

Installation

In systems with motors connected in parallel, the

electronic thermal relay (ETR) of the frequency

converter cannot be used as motor protection

for the individual motor. Consequently, additional

motor protection is required, such as thermistors

in each motor (or individual thermal relays) suitable

for frequency converter use.

Please note that the individual motor cable for each

motor must be summed and is not to exceed the

total motor cable length permitted.

■ Motor thermal protection

The electronic thermal relay in UL-approved frequency

converters has received the UL-approval for single

motor protection when parameter 128 has been set for

ETR Trip and parameter 105 has been programmed to

the rated motor current (see motor nameplate).

■ Electrical installation - brake cable

(Only standard with brake and extended with

brake. Typecode: SB, EB, DE, PB).

No. Function

81, 82 Brake resistor terminals

The connection cable to the brake resistor must be

screened. Connect the screen by means of cable

clamps to the conductive back plate at the frequency

converter and to the metal cabinet of the brake resistor.

Size the brake cable cross-section to match

the brake torque. See also Brake instructions,

MI.90.FX.YY and MI.50.SX.YY for further information

regarding safe installation.

NB!:

Please note that voltages up to 1099 V

DC, depending on the supply voltage, may

occur on the terminals.

■ Electrical installation - brake resistor

temperature switch

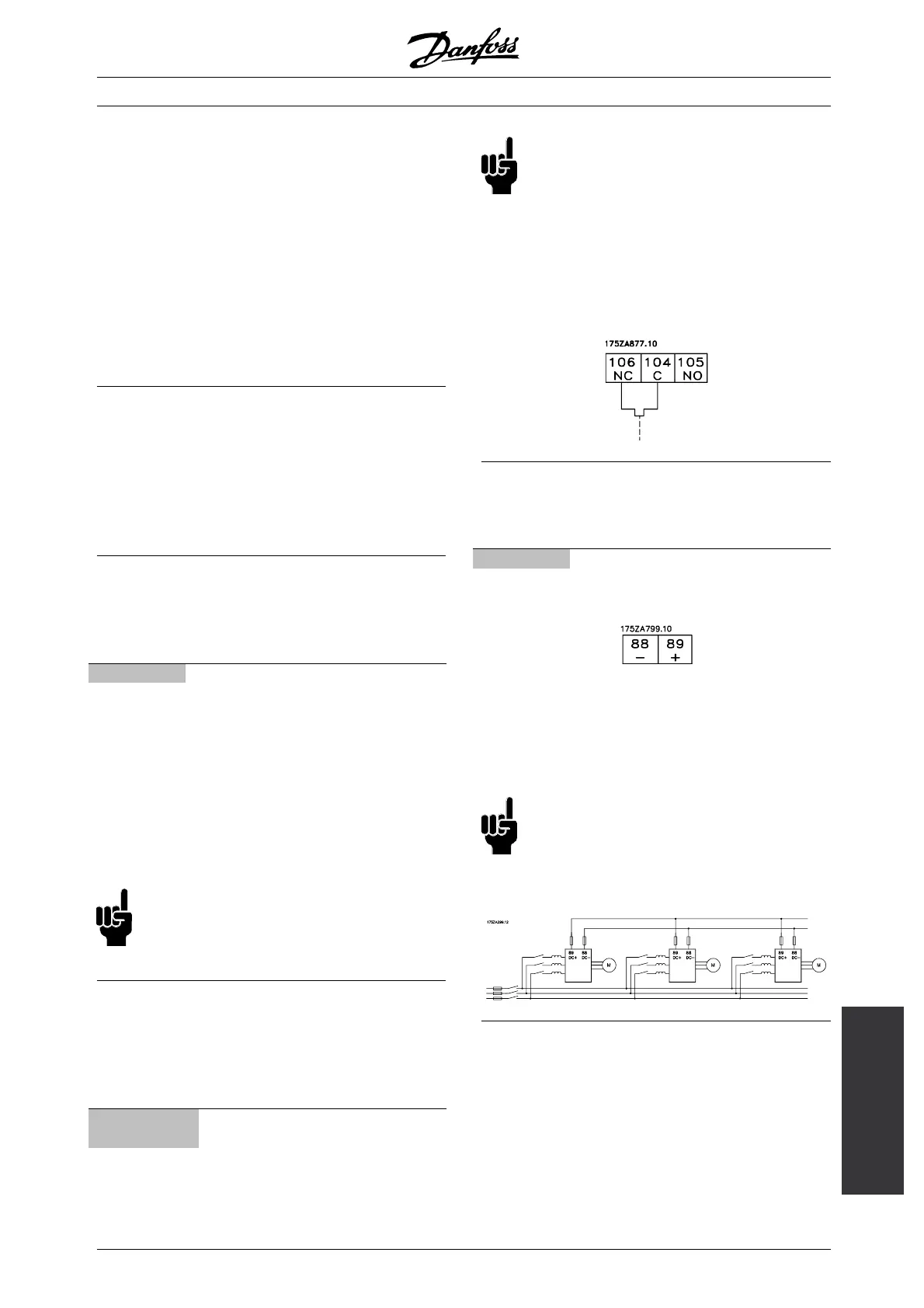

Torque: 0.5-0.6 Nm

Screw size: M3

No. Function

106, 104,

105

Brake resistor temperature switch.

NB!:

This function is only available on VLT 5032-5052,

200-240 V; VLT 5122-5552, 380-500 V; and

VLT 5042-5602, 525-690 V.

If the temperature of the brake resistor gets too high and

the thermal switch drops out, the frequency converter

will stop braking. The motor will start coasting.

A KLIXON switch must be installed that is ‘normally

closed’. If this function is not used, 106 and 104

must be short-circuited together.

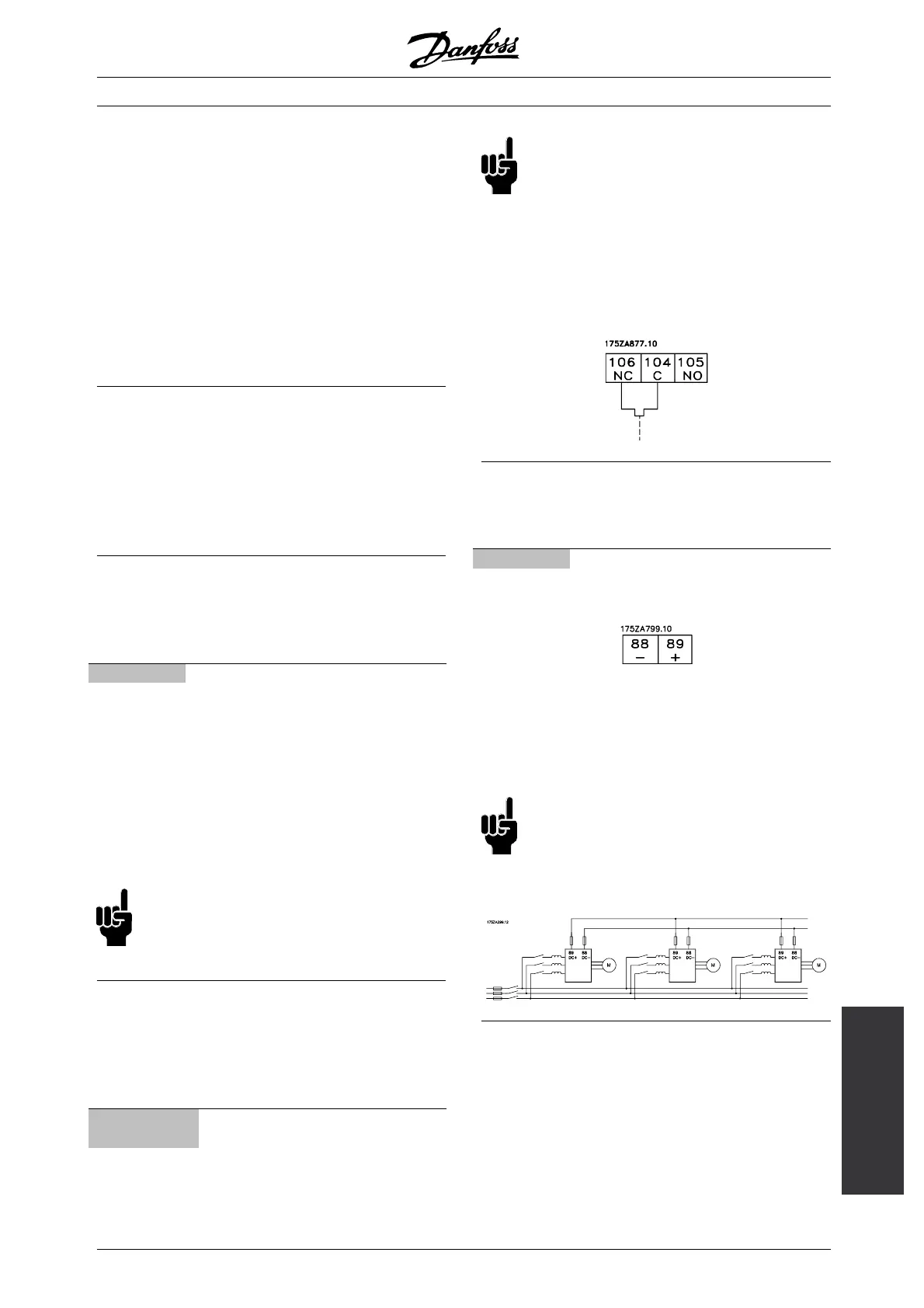

■ Electrical installation - loadsharing

(Only extended with typecode EB, EX, DE, DX).

No. Function

88, 89 Loadsharing

Terminals for loadsharing

The connection cable must be screened and

the max. length from the frequency converter

to the DC bar is 25 metres.

Load sharing enables linking of the DC intermediate

circuits of several frequency converters.

NB!:

Please note that voltages up to 1099 V DC

may occur on the terminals.

Load sharing calls for extra equipment. For

further information please consult Loadsharing

Instructions MI.50.NX.XX.

■ Tightening-up torques and screw sizes

The table shows the torque required when fitting

terminals to the frequency converter. For VLT

5001-5027 200-240 V, VLT 5001-5102 380-500 V

and VLT 5001-5062 525-600 V, the cables must be

fastened with screws. For VLT 5032 - 5052 200-240 V,

VLT 5122-5552 380-500 V, VLT 5042-5602 525-690

V the cables must be fastened with bolts.

These figures apply to the following terminals:

MG.51.A9.02 - VLT is a registered Danfoss trademark

45

Loading...

Loading...