Do you have a question about the Danfoss VLT 5016 and is the answer not in the manual?

Essential safety information and notes regarding handling the VLT adjustable frequency drive and its components.

Key regulations for safe operation, including disconnection from mains and protective earthing.

Precautions to prevent unexpected motor starts due to digital commands, bus commands, or faults.

Covers AC line supply, voltage imbalance, power factor, and various output characteristics for VLT 5000 series.

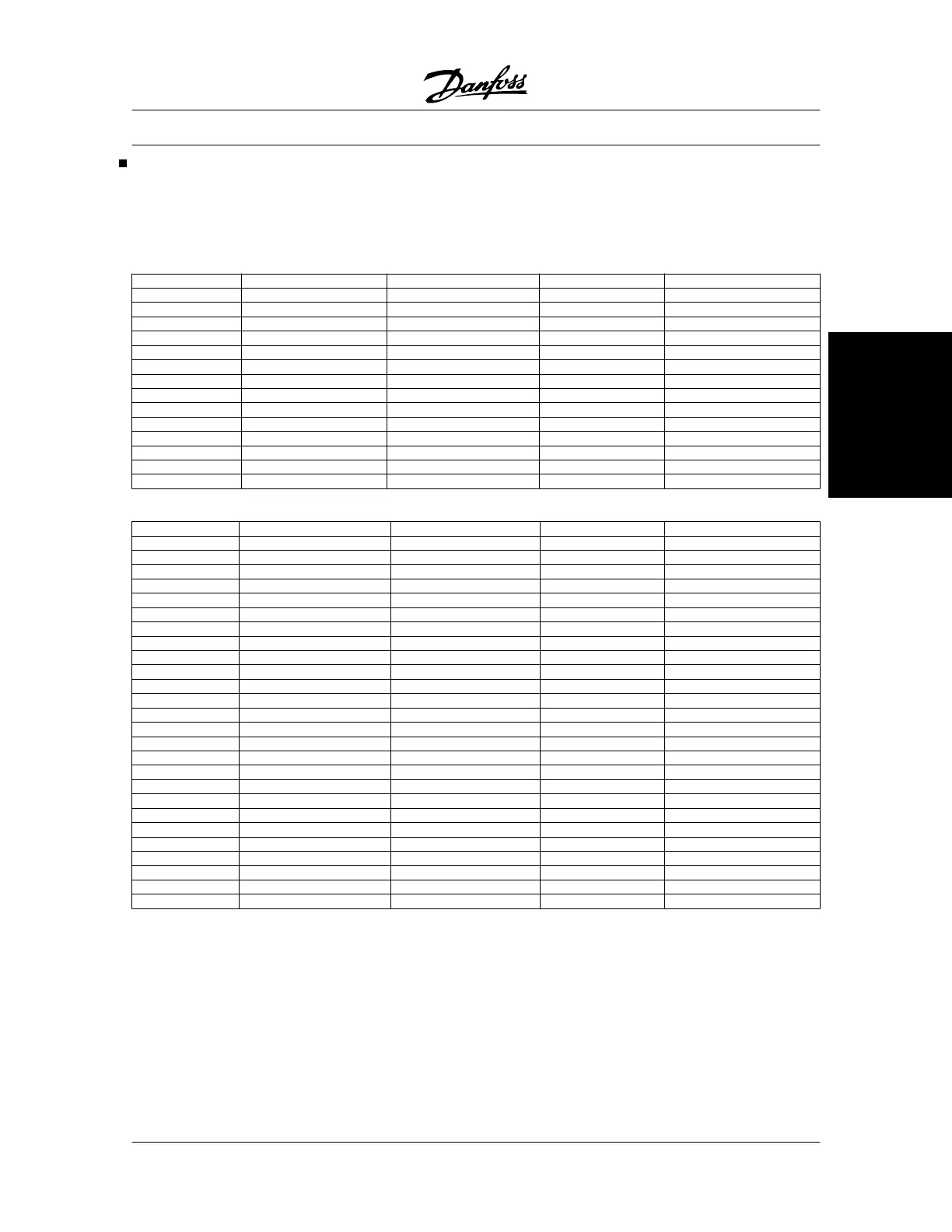

Detailed electrical specifications including output current, voltage, power, cable cross-sections, and fuses for various models.

Provides dimensional data (A, B, C, D, etc.) in mm for different enclosure types (Bookstyle, Compact) of the VLT 5000 series.

Guidelines for derating output current based on ambient temperature and enclosure type.

Instructions for vertical mounting, cooling, and minimum clearance requirements for proper installation.

Details on connecting the three mains phases and safety grounding, including RFI switch usage.

Diagrams and guidelines for connecting power cables to different VLT 5000 enclosure types.

Best practices for ensuring EMC-correct electrical installation, including cable selection and grounding.

Description of the Local Control Panel (LCP), its detachable nature, and main functions.

Explanation of the LCD display's different read-out states and how to interpret displayed information.

Detailed explanation of the functions assigned to each control key on the LCP for parameter setup and operation.

Step-by-step guide for initial configuration using the Quick Setup menu.

Instructions on how to select and change parameter values using the LCP.

Configuration options for controlling the drive locally via LCP or remotely via terminals or serial port.

Parameters for setting motor characteristics like power, voltage, frequency, current, and speed.

Configuration of PID controllers for process and speed control, including proportional, integral, and derivative gains.

Configuration for functions like brake control, overload protection, flying start, and quick discharge.

Parameters for configuring Modbus RTU protocol, address, baud rate, and telegram profiles.

Common issues like motor running unevenly, not running, or not braking, with troubleshooting steps.

Interpretation of various status messages displayed on the LCP, such as 'FREQUENCY HIGH', 'FEEDBACK LOW'.

Comprehensive list of warnings and alarms, their descriptions, and fault codes for diagnosis.

Example programming for controlling a conveyor belt with digital inputs for start/stop and speed.

Example of setting up a PID controller for a ventilation system to maintain a constant temperature.

Example programming for VLT 5000 PID speed control for a conveyor belt with encoder feedback.

Example programming for torque control of a conveyor belt to maintain constant force.

Discussion on electrical interference, motor cable screening, and reducing noise levels for EMC compliance.

Best practices for ensuring EMC-correct electrical installation, including cable selection and grounding.

Explanation of CE labelling purpose and compliance with EU directives for electrical equipment.