Conventions

Numbered lists indicate procedures.

Bullet lists indicate other information and description of

illustrations.

Italicised text indicates

•

cross reference

•

link

•

footnote

•

parameter name, parameter group name,

parameter option

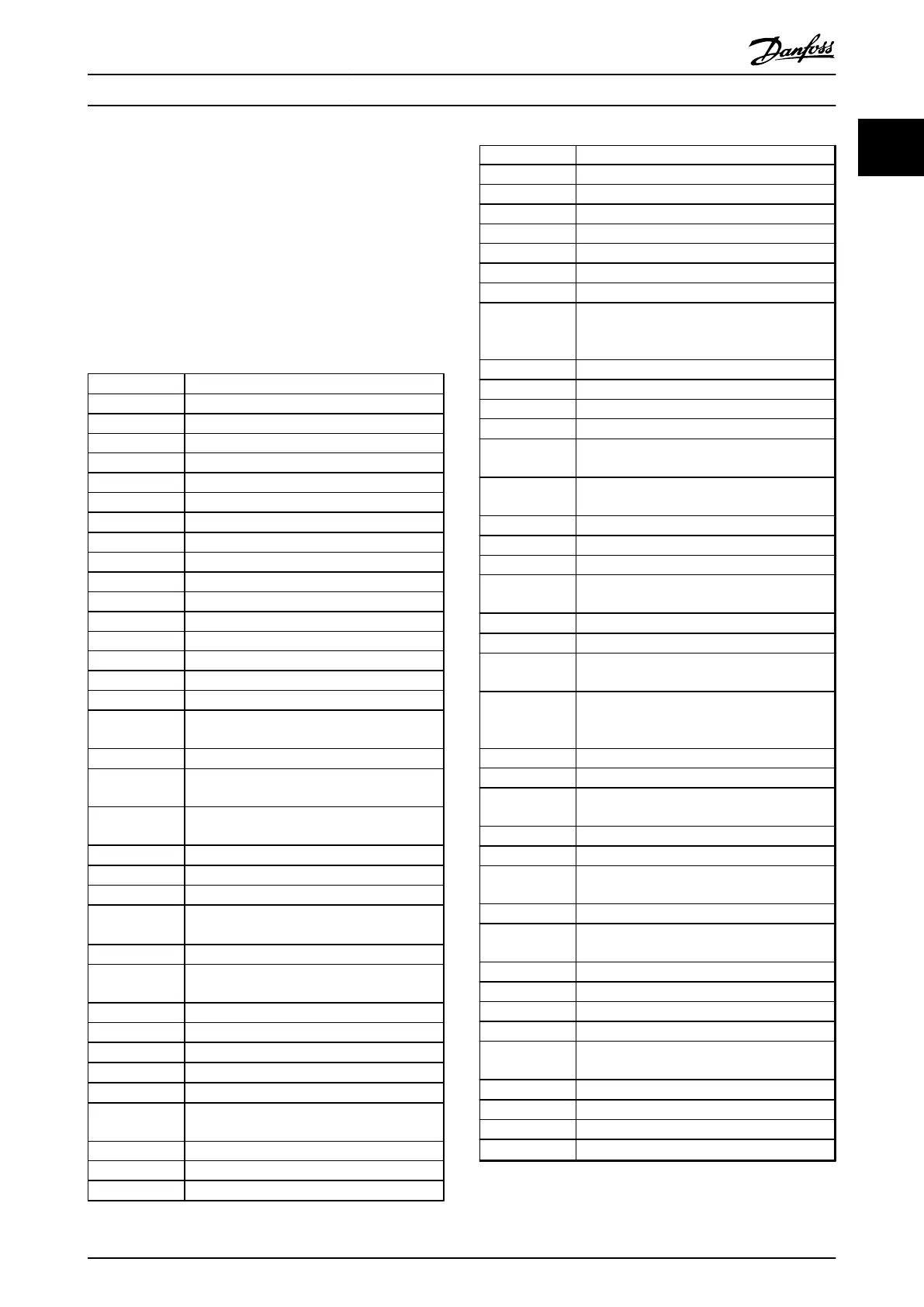

60° AVM 60° Asynchronous Vector Modulation

A Ampere/AMP

AC Alternating current

AD Air discharge

AI Analog Input

AMA Automatic Motor Adaptation

AWG American wire gauge

°C

Degrees Celsius

CD Contant discharge

CM Common mode

CT Constand Torque

DC Direct current

DI Digital Input

DM Differential mode

D-TYPE Drive Dependent

EMC Electro Magnetic Compatibility

ETR Electronic Thermal Relay

f

JOG

Motor frequency when jog function is

activated

f

M

Motor frequency

f

MAX

The maximum output frequency the frequency

converter applies on its output

f

MIN

The minimum motor frequency from

frequency converter

f

M,N

Nominal motor frequency

FC Frequency converter

g Gram

Hiperface

®

Hiperface

®

is a registered trademark by

Stegmann

hp Horsepower

HTL HTL encoder (10-30 V) pulses - High-voltage

Transistor Logic

Hz Hertz

I

INV

Rated Inverter Output Current

I

LIM

Current limit

I

M,N

Nominal motor current

I

VLT,MAX

The maximum output current

I

VLT,N

The rated output current supplied by the

frequency converter

kHz Kilohertz

LCP Local Control Panel

lsb Least significant bit

m Meter

mA Milliampere

MCM Mille Circular Mil

MCT Motion Control Tool

mH Millihenry Inductance

min Minute

ms Millisecond

msb Most significant bit

η

VLT

Efficiency of the frequency converter defined

as ratio between power output and power

input

nF Nanofarad

NLCP Numerical Local Control Panel

Nm Newton Meters

n

s

Synchronous Motor Speed

On-line/Off-line

Parameters

Changes to on-line parameters are activated

immediately after the data value is changed.

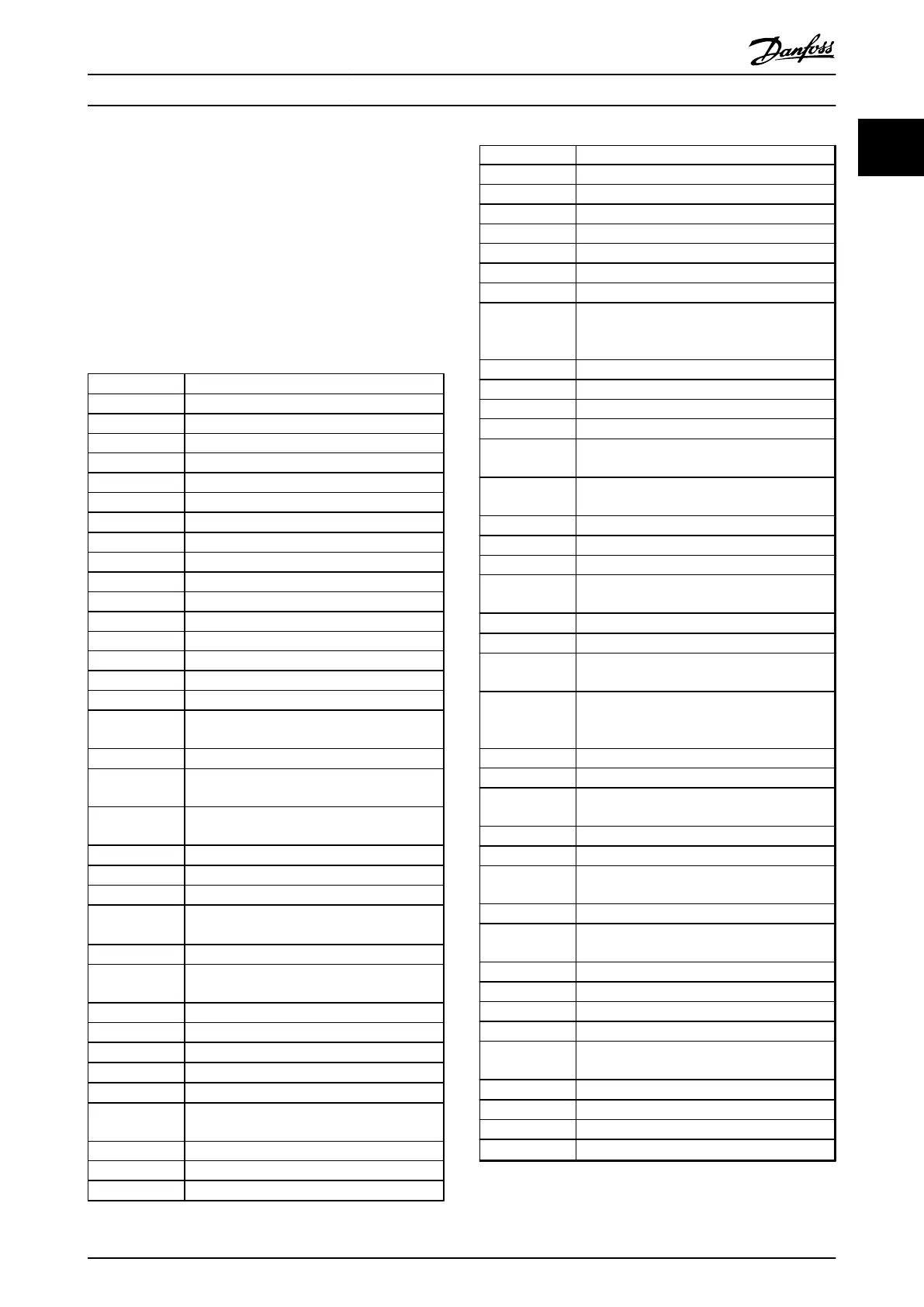

P

br,cont.

Rated power of the brake resistor (average

power during continuous braking)

PCB Printed Circuit Board

PCD Process Data

PELV Protective Extra Low Voltage

P

m

Frequency converter nominal output power as

HO

P

M,N

Nominal motor power

PM motor Permanent Magnet motor

Process PID The PID regulator maintains the desired speed,

pressure, temperature, etc.

R

br,nom

The nominal resistor value that ensures a

brake power on motor shaft of 150/160% for 1

minute

RCD Residual Current Device

Regen Regenerative terminals

R

min

Minimum permissible brake resistor value by

frequency converter

RMS Root Mean Square

RPM Revolutions Per Minute

R

rec

Resistor value and resistance of the brake

resistor

s Second

SFAVM Stator Flux oriented Asynchronous Vector

Modulation

STW Status Word

SMPS Switch Mode Power Supply

THD Total Harmonic Distortion

T

LIM

Torque limit

TTL TTL encoder (5 V) pulses - Transistor Transistor

Logic

U

M,N

Nominal motor voltage

V Volts

VT Variable Torque

VVC

plus

Voltage Vector Control

Table 1.2 Abbreviations

Introduction

VLT

®

Automation Drive FC 300 Operating Instructions

MG33U402 - Rev. 2013-12-16 5

1

1

Loading...

Loading...