VLT

®

FCD Series

Programming, FCD

300

Select ETR warning if you want a warning when the

motor is overloaded according to the calculations.

You can also programme the frequency converter to

give a warning signal via the digital output.

Select ETR Trip ifyouwantatripwhenthemotor

is overloaded according to the calculations.

Select ETR w arning 1-4 if you want a warning when

the motor is overloaded according to the calculations.

You can also programme the frequency converter to

give a warning signal via one of the digital outputs.

Select ETR Trip 1-4 if you want a trip when the motor

is overloaded according to the calculations.

NB!:

This function cannot protect the individual

motors in the case of motors linked in parallel.

130 Start frequency

(START FREQUENCY)

Value:

0.0 - 10.0 Hz

✭ 0.0 Hz

Function:

Thestartfrequencyisactiveforthetimesetin

parameter 120 Start delay, after a start command.

The output frequency will ’jump’ tothenextpreset

frequency. Certain motors, such as conical anchor

motors, need an extra voltage/start frequency

(boost) at start to disengage the mechanical brake.

To achieve this parameters 130 Start freque ncy

and 131 Initial voltage are used.

Description of choice:

Set the required start frequency. It is a precondition

that parameter 121 Start function,issetto

Start frequency/voltage clockwise [3] or Start

freque ncy voltage in reference direction [4] and

that in parameter 120 Start delay atimeisset

and a reference signal is present.

NB!:

If parameter 123 is set higher than parameter

130, the start delay function (parameter

120 and 121) will be skipped.

131 Initial voltage

(INITIAL VOLTAGE)

Value:

0.0 - 200.0 V

✭ 0.0 V

Function:

Initial voltage is active for the time set in parameter

120 Start delay , after a start command

.This

parameter can be used for example for lifting/dropping

applications (conical anchor motors).

Description of choice:

Set the required voltage necessary to cut out the

mechanical brake. It is assumed that parameter

121 Start function,issettoStart frequency/voltage

clockwise [3] or Start frequency/voltage in reference

direction [4] and that in parameter 120 Start delay a

time is set, and that a reference signal is present.

132 DC brake voltage

(DC BRAKE VOLTAGE)

Value:

0 - 100% of max. DC brake voltage

✭ 0%

Function:

In this parameter, the DC brake voltage is set which is

to be activated at stop when the DC brake frequency

set in parameter 127 DC brake cut-in frequency is

reached, or if DC braking inverse isactiveviaadigital

input or via serial communication. Subsequently,

the DC brake voltage will be active for the time

set in parameter 126 DC brake time.

Description of choice:

To be set as a percentage value of the max. DC

brake voltage, which depends on the motor.

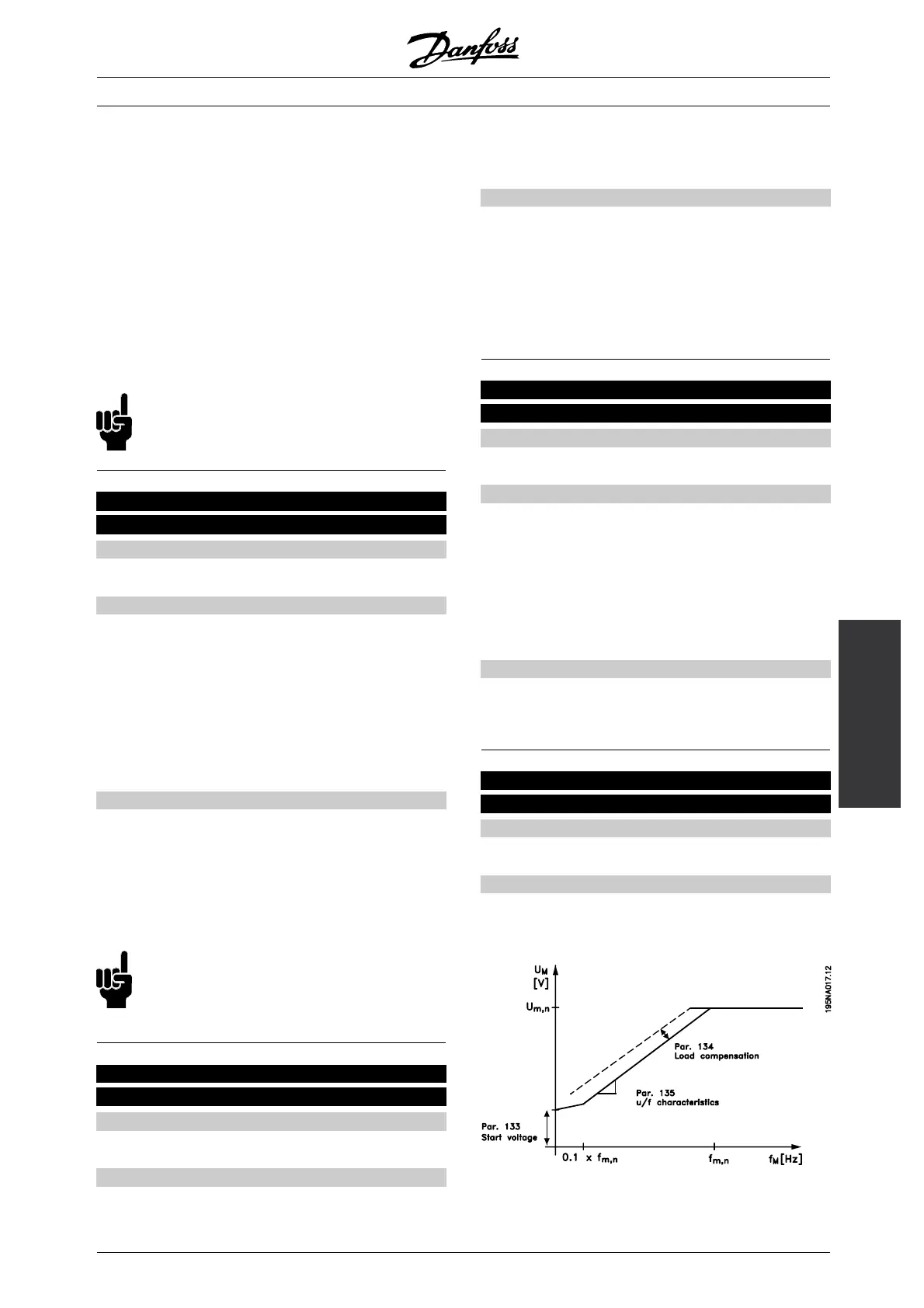

133 Start voltage

(START VOLTAGE)

Value:

0.00 - 100.00 V

✭ Depends on unit

Function:

A higher start torque can be obtained by increasing

the start voltage. Small motors (< 1.0 kW)

normally require a high start voltage.

✭ = factory setting. () = display text [] = value for use in communication via serial communication port

MG.04.B7.02 - VLT is a registered Danfoss trademark

45

Loading...

Loading...