08SP11R

08SP11T

16SP11R 08SP11TS 16SP11TS

S /S

X0

X1

X2

X3

C0

Y0

C1

Y1

C2

Y2

C3

Y3

.

.

.

.

.

S /S

X0

X1

X2

X3

C0

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

X4

X5

X6

X7

S /S

X0

X1

X2

X3

UP

Y0

Y1

Y2

Y3

ZP

.

.

.

.

.

.

.

.

S /S

X0

X1

X2

X3

UP

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

X4

X5

X6

X7

ZP

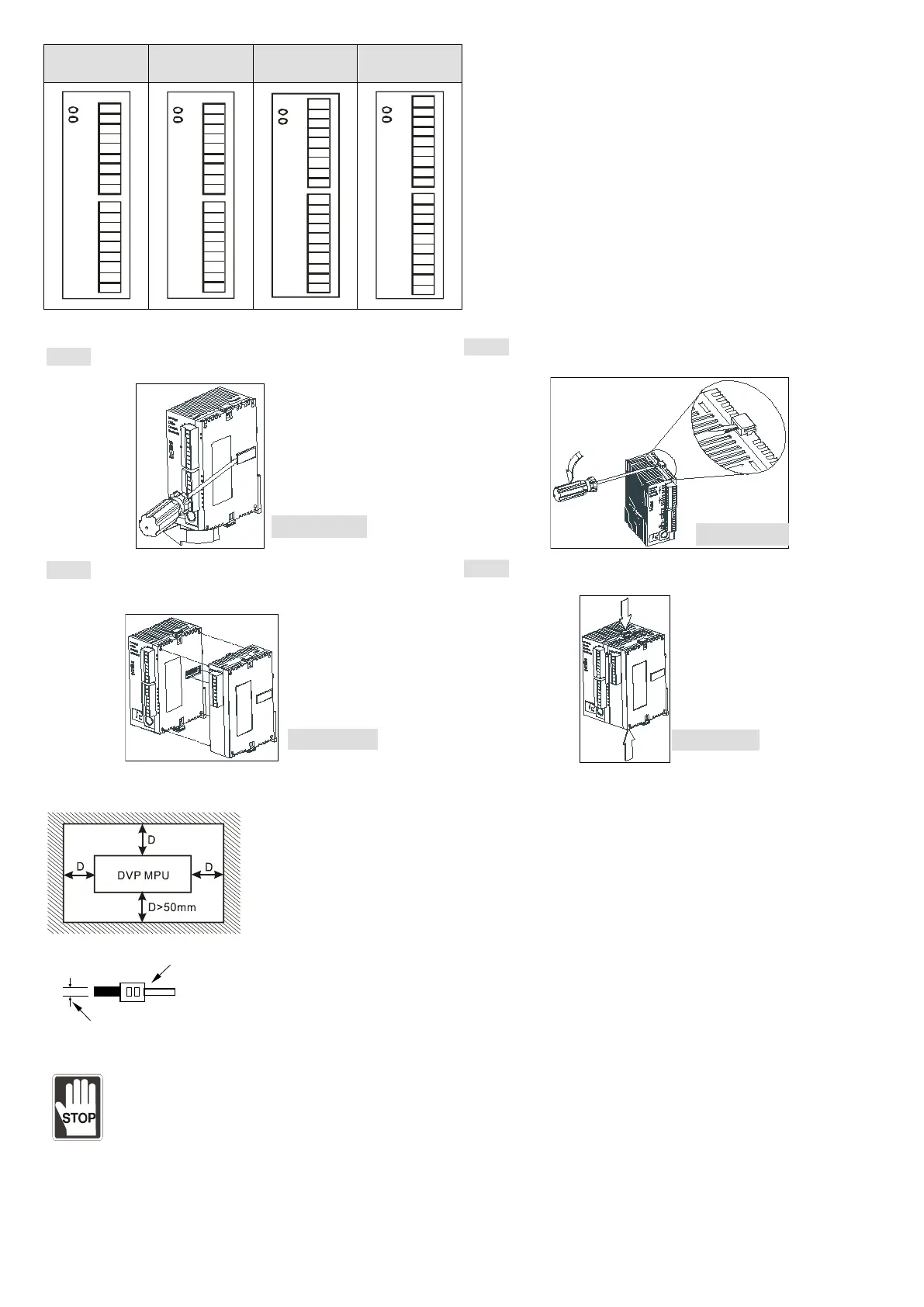

Connection

Step 1 Screw open the side cover of the extension unit,

and you will see the connection port.

Step 2 Lift the fixing clip by the screwdriver.

Step 3 Adjust the positioning hole of the MPU and the

extension unit. Meet the connection port on the MPU with

the extension unit to tightly connect the two.

Step 4 Fasten the fixing clip on the extension unit to

complete the connection.

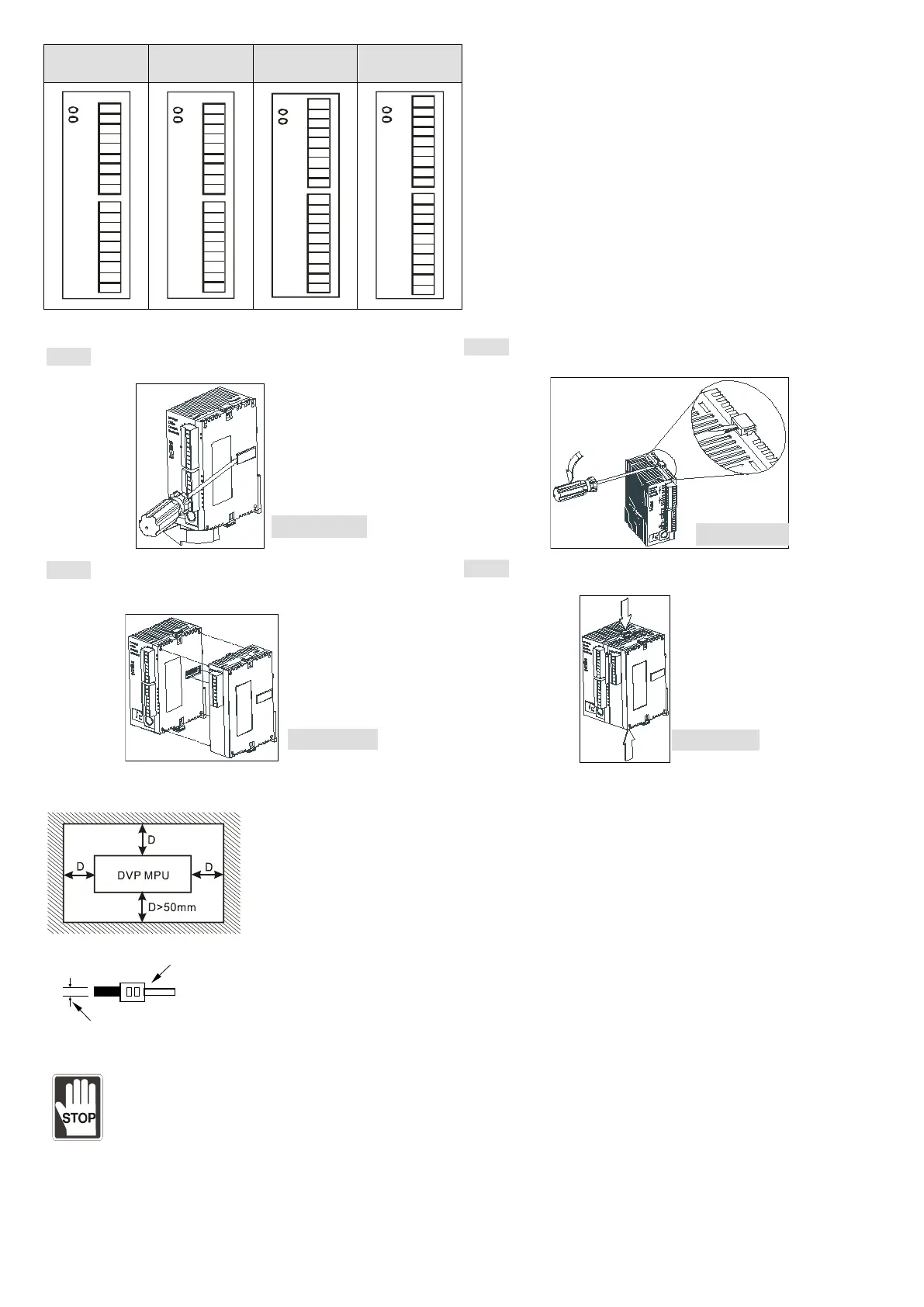

Installation & Wiring

Install the PLC in an enclosure with sufficient space around it to allow heat dissipation (as shown in the figure below).

DVP-

PLC can be secured to a cabinet by using the DIN rail of 35mm in height and 7.5mm in

depth. When mounting PLC to the DIN rail, be sure to use the end bracket to stop any

side-to-side movement of the PLC and reduce the chance of wires being loosen. A small

retaining clip is at the bottom of the PLC. To secure PLC to the DIN rail, place the clip onto

the rail and gently push it up. To remove it, pull the retaining clip down and gently

PLC from the DIN rail.

1. Use 22-16AWG (1.5mm) single or multiple core wire on I/O wiring terminals. The

specification of the terminal is shown in the figure on the left hand side. The PLC terminal

screws shall be tightened to 1.95kg-cm (1.7 in-lbs). Use 65/75°C copper wires only.

2. DO NOT place the I/O signal wires and power supply wire in the same wiring duct.

Notes

DO NOT install PLC in an environment with

Dust, smoke, metallic debris, corrosive or flammable gas

High temperature, humidity

Direct shock and vibration

During the engineering

1. DO NOT drop tiny metallic conductor into the PLC when screwing and wiring.

2. There should be a margin of more than 50mm between the PLC and other control devices, and the PLC should be

placed away from high voltage wire and power equipment.

Loading...

Loading...