ENGLISH

34

NOTE: The arrow on the mode selector dial

6

must be

pointing at a mode symbol at all times. There are no

operable positions inbetween. It may be necessary to briefly

run the motor after having changed from 'hammering only'

to 'rotary' modes in order to align thegears.

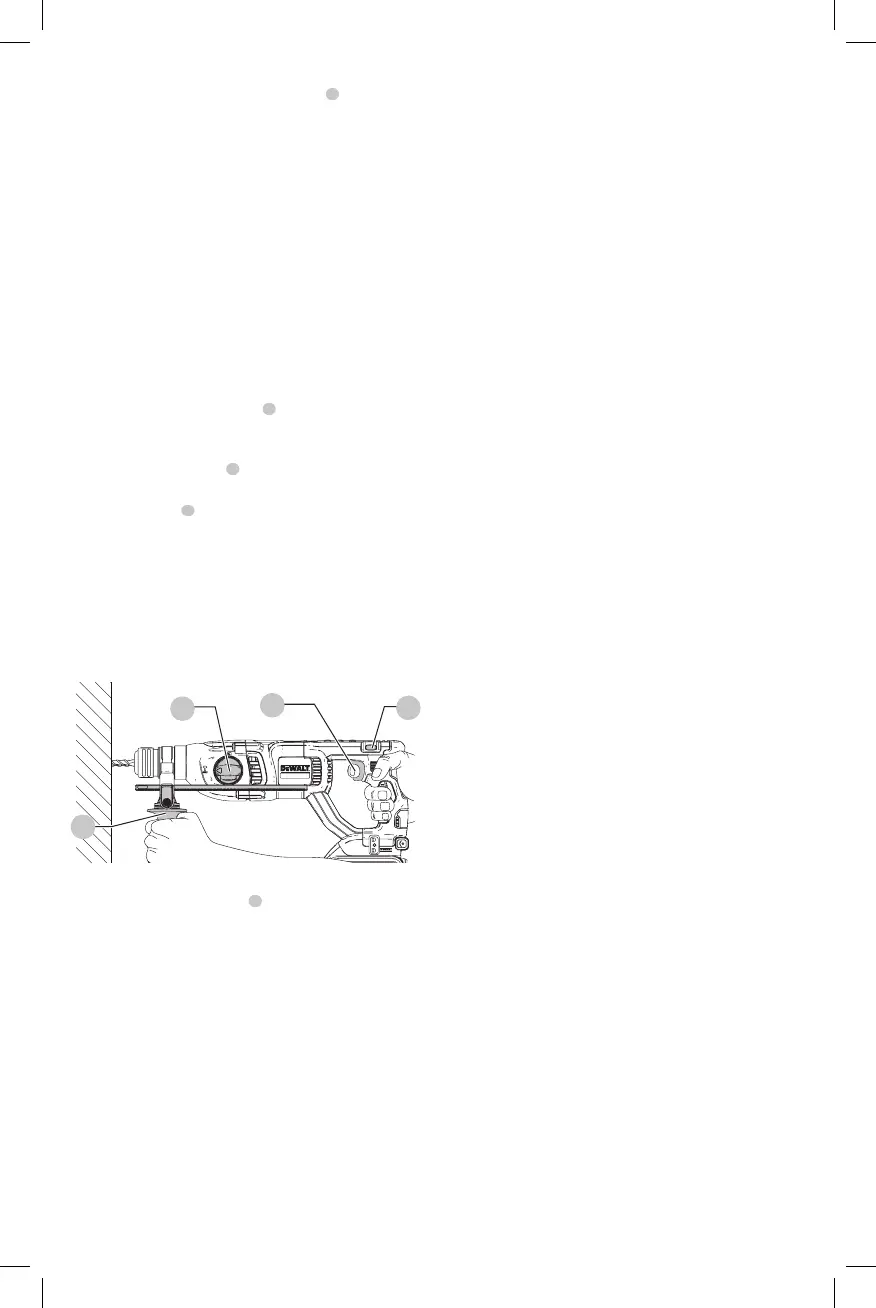

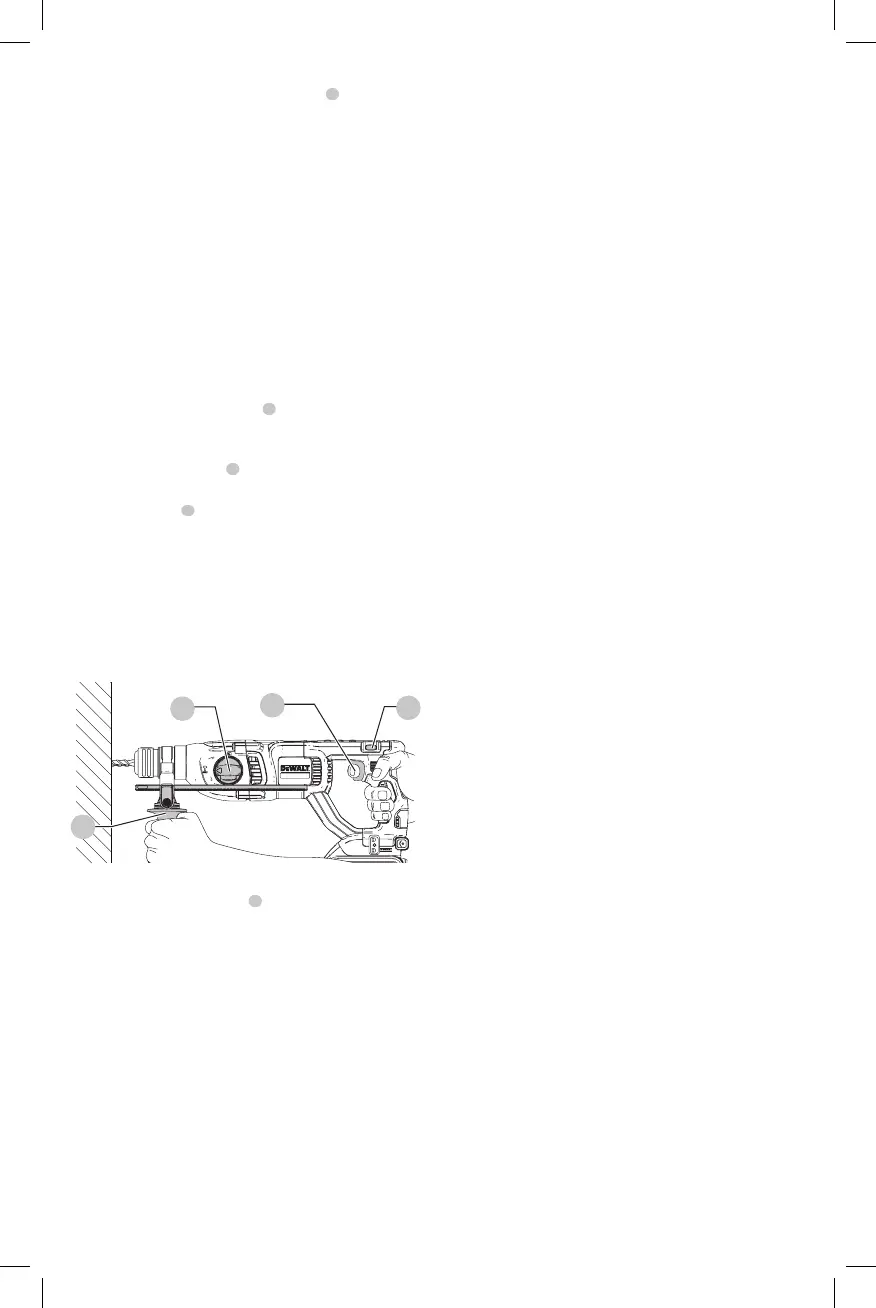

Performing an Application (Fig. A, J)

WARNING: TO REDUCE THE RISK OF PERSONAL

INJURY, ALWAYS ensure workpiece is anchored or

clamped firmly. If drilling thin material, use a wood

“back-up” block to prevent damage to thematerial.

WARNING: Always wait until the motor has come to

a complete standstill before changing the direction

ofrotation.

1. Choose and install the appropriate chuck, adapter, and/

or bit onto to the tool. Refer to Bit and Bit Holder.

2. Using the mode selector dial

6

, selectthe mode

appropriate to desired application. Refer to

OperationModes.

3. Adjust the side handle

3

asnecessary.

4. Select the direction ofrotation using the forward/

reverse button

4

. When changing the position of the

control button, be sure the trigger isreleased.

- To select forward rotation, press the for ward/re verse

control button on the right side of thetool.

- To select reverse, press the forward/reverse control

button on the left side of thetool.

NOTE: The center position of the control button

locks the tool in the off position.

Fig. J

6

3

5

4

5. Place the bit/chisel on the desired location.

6. Depress the trigger switch

5

. The farther you depress

the trigger switch, the faster the tool will operate. For

maximum tool life, use variable speed only for starting

holes orfasteners.

7. To stop the hammer, release the switch.

Recommendations for Tool Operation

• Large (5/16" to 1/2" [7.9 mm to 12.7 mm]) holes in steel

can be made easier if a pilot hole (5/32" to 3/16" [4 mm

to 4.8 mm]) is drilledfirst.

• When drilling, always apply pressure in a straight line

with the bit, but do not push hard enough to stall the

motor or deflect thebit. A smooth even flow of material

indicates the proper drilling rate.

• If drilling thin material or material that is prone to

splinter, use a wood “back-up” block to prevent damage

to thework piece.

WARNING:

• Do not use this tool to mix or pump easily

combustible or explosive fluids (benzine,

alcohol,etc.).

• Do not mix or stir inflammable liquids

labelledaccordingly.

MAINTENANCE

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An

accidental start-up can causeinjury.

Your D

WALT power tool has been designed to operate

over a long period of time with a minimum of maintenance.

Continuous satisfactory operation depends upon proper

tool care and regular cleaning.

Cleaning

WARNING: Blow dirt and dust out of all air vents with

clean, dry air at least once a week. To minimize the

risk of eye injury, always wear approved eye protection

when performingthis.

WARNING: Never use solvents or other harsh

chemicals for cleaning the non-metallic parts of

the tool. These chemicals may weaken the plastic

materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid

get inside the tool; never immerse any part of the tool

into aliquid.

Accessories

WARNING: Since accessories, other than those

offered by

, have not been tested with this

product, use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only

recommended accessories should be used with

thisproduct.

Various types of SDS Plus drill bits and chisels are available

as anoption. Accessories and attachments used must be

regularly lubricated around the SDS Plusfitment.

Recommended accessories for use with your tool are

available at extra cost from your local dealer or authorized

service center. Recommended accessories for use with your

tool are available at extra cost from your local dealer or

authorized service center

Repairs

The charger and battery pack are notserviceable.

WARNING: To assure product SAFETY and

RELIABILITY, repairs, maintenance and adjustment

(including brush inspection and replacement) should

be performed by a

factory service center

or a

authorized service center. Always use

identical replacementparts.

Loading...

Loading...