ENGLISH

13

DAILY MAINTENANCE CHART

ACTION Clean magazine, feed pawl, and contact

tripmechanism.

WHY Permits smooth operation of magazine,

reduces wear, and preventsjams.

HOW Blowing off the tool with compressed air is the

most effective way to clean the tool. The use

of oils, lubricants periodically or solvents is not

recommended as they tend to attract debris

and/or damage the plastic parts of thetool.

ACTION Before each use, check to ensure all screws

and fasteners are tight andundamaged.

WHY Prevents jams and premature failure of

toolparts.

HOW Tighten loose screws using the appropriate

hex wrench orscrewdriver.

Cleaning

WARNING: Blow dirt and dust out of all air vents with

clean, dry air at least once a week. To minimize the risk

of eye injury, always wear ANSI Z87.1 approved eye

protection when performingthis.

WARNING: Never use solvents or other harsh

chemicals for cleaning the non-metallic parts of

the tool. These chemicals may weaken the plastic

materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid

get inside the tool; never immerse any part of the tool

into aliquid.

Accessories

WARNING: Since accessories, other than those

offered by

, have not been tested with this

product, use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only

recommended accessories should be used with

thisproduct.

Recommended accessories for use with your tool

are available at extra cost from your local dealer or

authorized service center. If you need assistance in

locating any accessory, please contact

Industrial

Tool Co., 701East Joppa Road, Towson, MD 21286, call

1-800-4-

(1-800-433-9258) or visit our website:

www.dewalt.com.

Replacing the Return Spring and Profile

WARNING: For your own safety, read the tool

instruction manual before using any accessory.

Failure to heed these warnings may result in serious

personal injury and damage to the tool and the

accessory. When servicing this tool, use only identical

replacementparts.

CAUTION: If you don't feel comfortable servicing your

tool, take it to a

authorized service center.

The user should only attempt to service the springs

and profile. All other service should be completed by

an authorized

servicecenter.

CAUTION: Do not lubricate any of the replacement

parts. Lubrication can damage the parts and seriously

affect the life and performance of thetool.

NOTICE: All the mechanical parts of the spring

replacement kit are shown for convenience and

verification of inclusion.

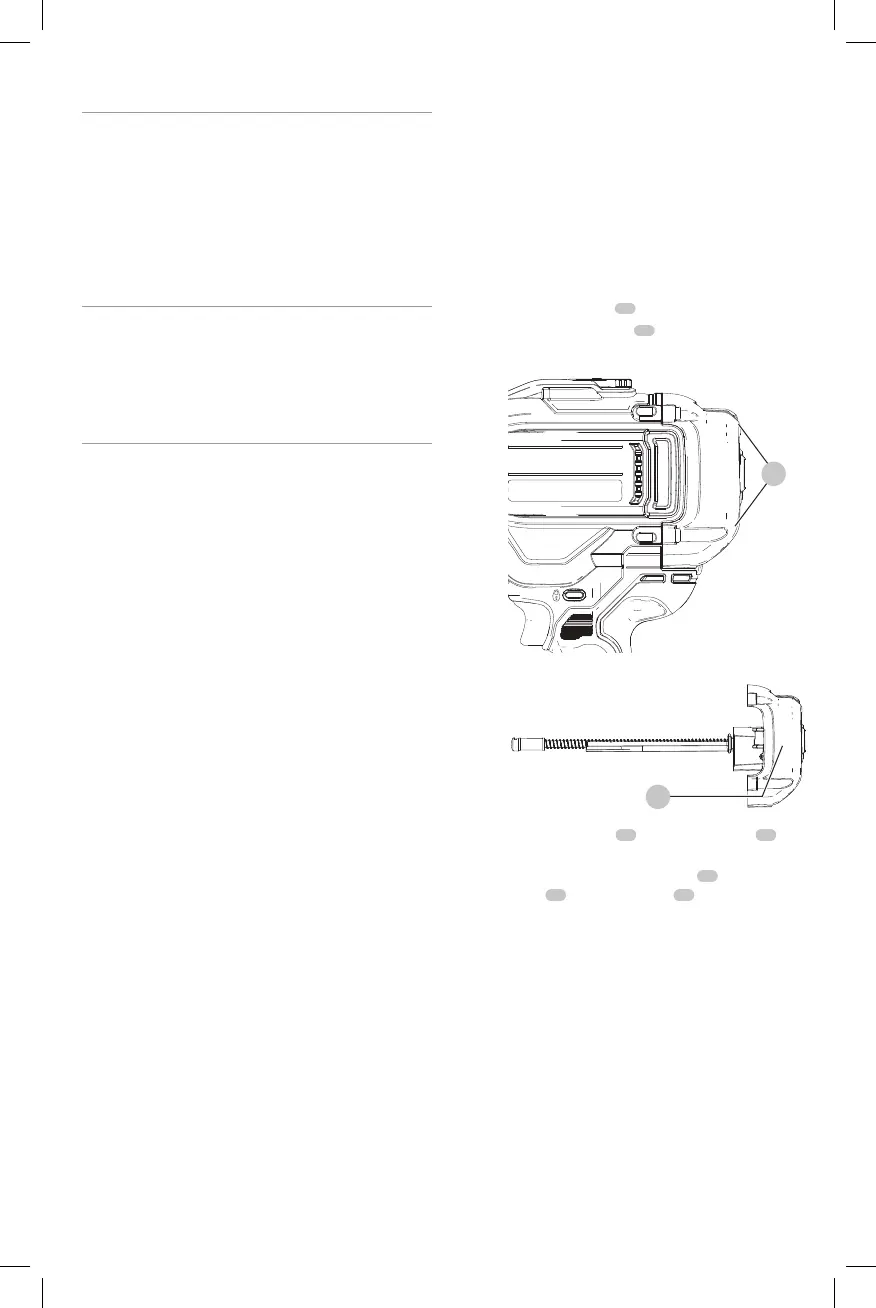

Return Spring Replacement (Fig. J–M)

To Change Broken or Worn Return Spring

NOTE: Use only the correct

accessory spring

replacementkit.

1. Loosen the four screws

15

on the back of the unit.

2. Remove the return system

16

from the unit. Refer to

FigureK.

15

Fig.J

Fig. K

16

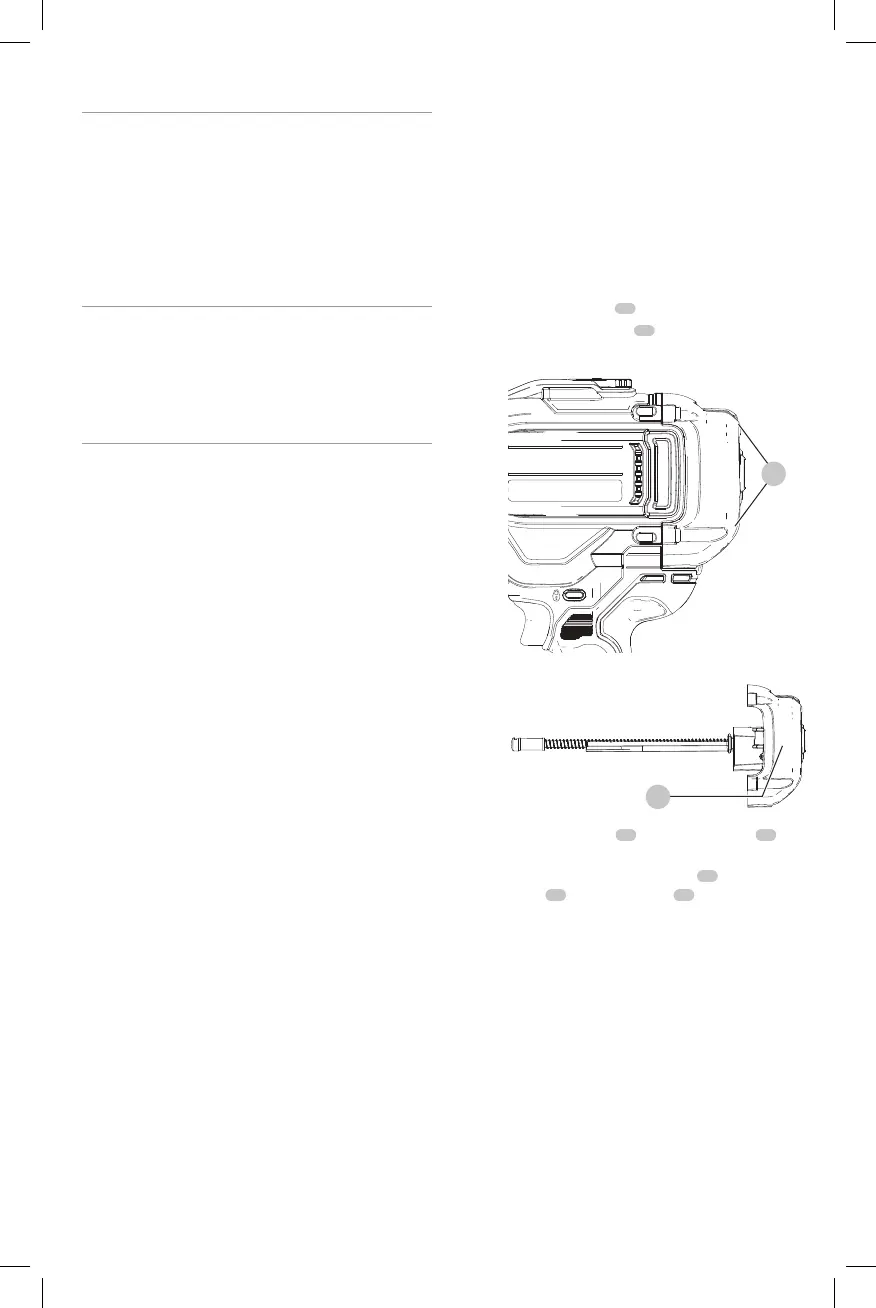

3. Slide the spring rail clip

17

off of the spring rail

18

.

Refer to FigureL.

4. Twist and remove the spring bumper

19

and remove

the washer

20

and return spring

21

. Refer to FigureM.

Loading...

Loading...