5

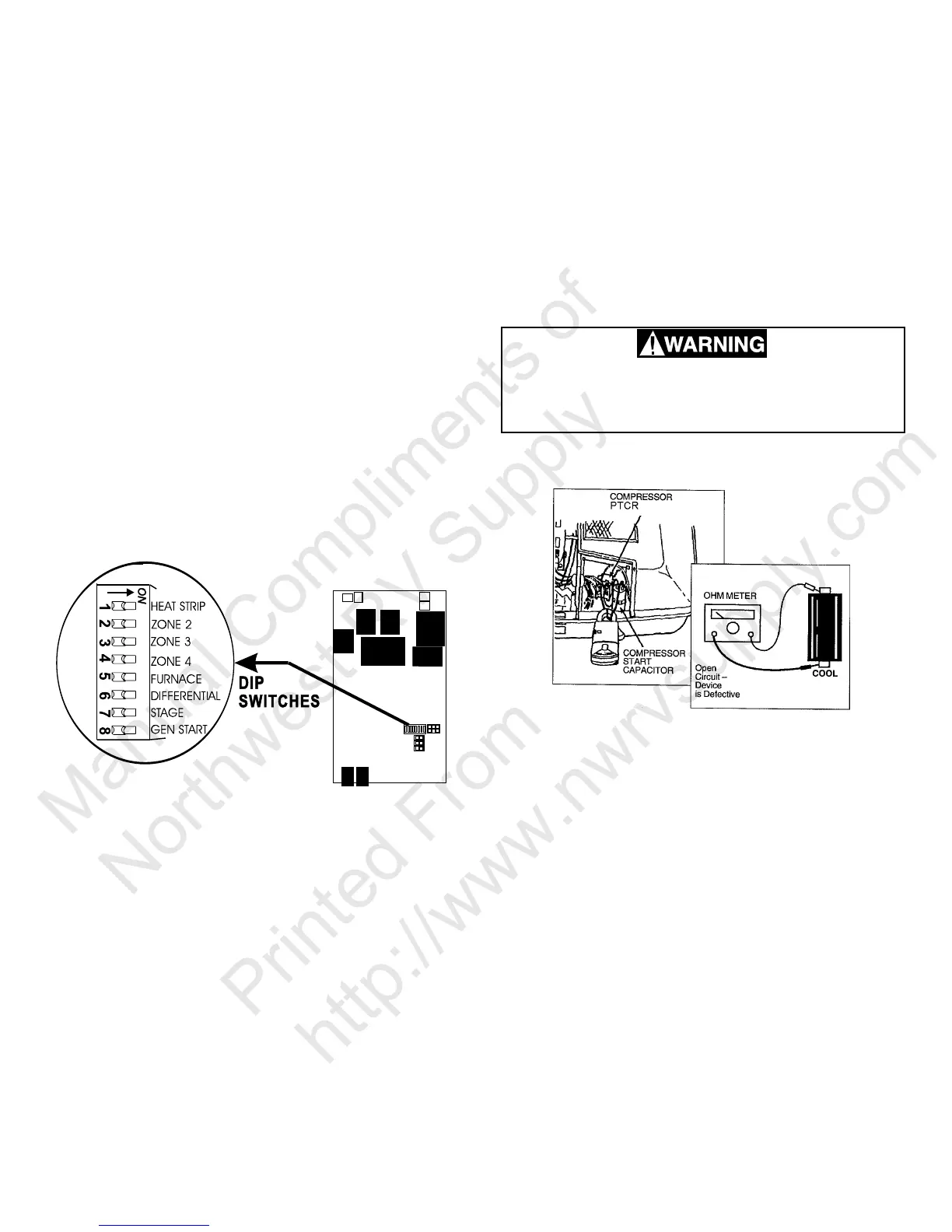

FIG. 9

Use an AC light bulb to test if the relays on the board

are completing a circuit. Check from the common

(white wire) to:

“NO” is a black or blue wire on the compressor relay

Terminal T1 is a black wire for high fan speed

Terminal T2 is the reversing valve on heat pumps. If

the violet wire is connected to T4 (Violet), it will oper-

ate in reverse of the mode selected.

Terminal T3 is a red wire for low fan speed

Note: Do not use a voltmeter to do these checks as

it will give erroneous readings.When the Comfort Con

trol Center is set to operate the heat pump the fan will

operate in the low speed only the Auto fan mode.

If the circuit is completed and that component is not

operating, the problem is in the wiring to the compo-

nent.

d. Dual Basement Air Conditioners and Heat Pumps

The operation of the dual air conditioner and heat pump

can be checked in the same manner as the single

basement air conditioner and heat pump. The stage

dip switch (switch 7) is turned to the “ON” position to

control the operation of the second compressor. See

FIG. 8.

Use a 115 volt AC light bulb to check from common

(white wire) to the other terminals to determine if the

circuits are being completed. If the circuit is com-

plete the light will illuminate.

Note: When the Comfort Control Center is set to op-

erate the heat pump the fan will operate in the low

speed only the Auto fan mode.

9. REVERSING VALVE

The reversing valve is the heart of a heat pump. It changes

the direction of the refrigerant flow through the coils, and

changes the system from cooling to heating.

The reversing valve’s solenoid can be energized in either the

heat or cool mode of operation. Duo-Therm roof top heat

pumps have the solenoid energized in the cool mode.

One method of checking the reversing valve is to feel the

refrigerant line at the top of the inside coil. In the COOL

mode, this line will be cool to the touch. In the heat mode

the line will be warm or hot to the touch. If you do not feel a

FIG. 8

cold line in the cooling mode, the direction of flow is not

correct.

Check the solenoid coil for ohms continuity. An open cir-

cuit (no continuity) shows the solenoid is defective and must

be replaced.

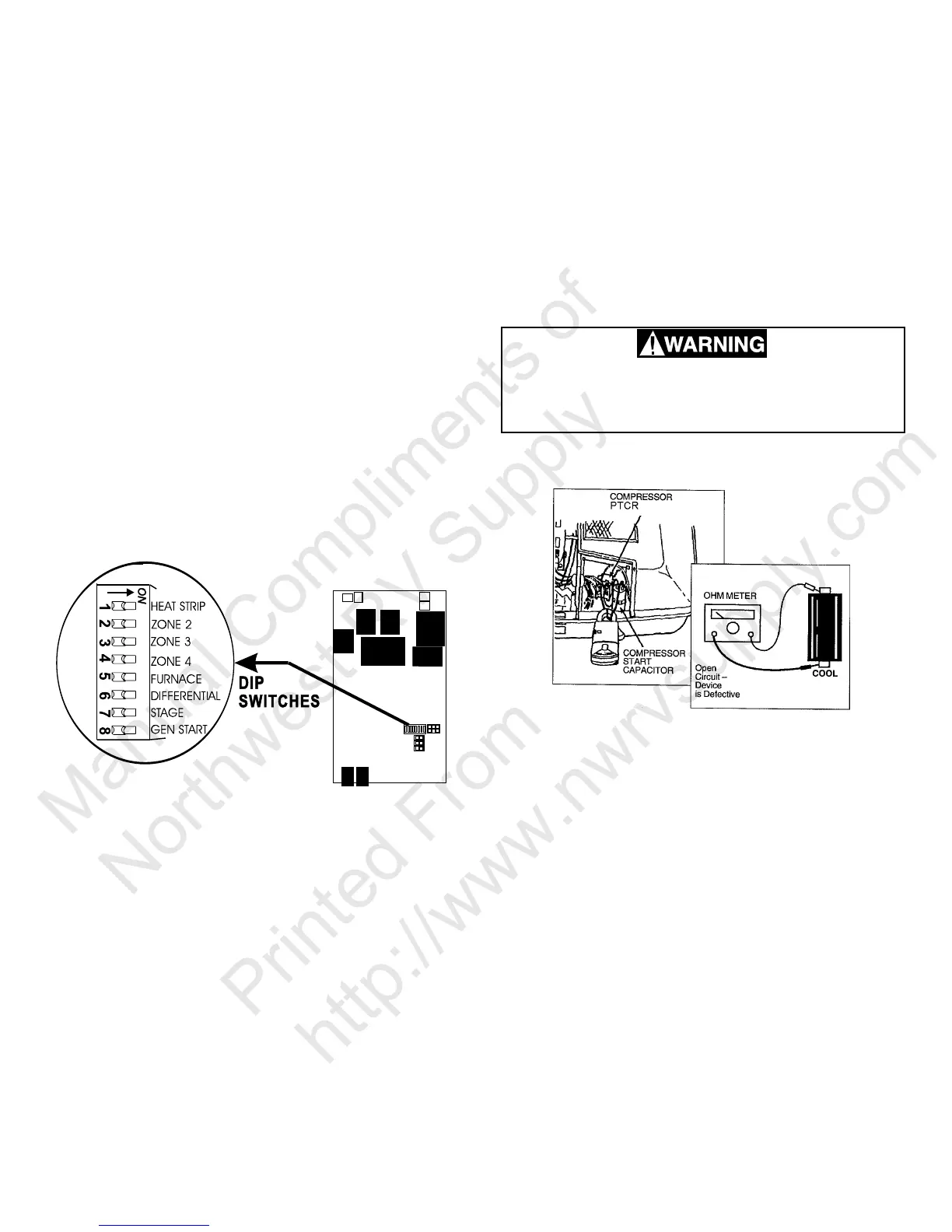

10. PTCR DEVICE

The positive temperature coefficient resistor/PTCR has re-

placed the compressor start relay and in some cases the

start capacitor. It should be checked in two different ways:

1. Check continuity. Turn “OFF” the AC power at the main

breaker and Comfort Control Center system switch. Dis-

connect the PTCR from the circuit. Using an ohmme-

ter,check for continuity through the PTCR. If there is no

continuity the PTCR is open and needs to be replaced.

This is an energized circuit. Shock can oc-

cur if not tested properly. Testing is to be

done by a qualified service technician.

2. The second check is an amp reading. Clamp an amme-

ter around the wire from the start capacitor. See FIG. 9.

Turn on the AC power and set the Comfort Control Cen-

ter to the cooling mode. When the compressor starts,

the ammeter should show a reading for approximately

one second. If there is no amperage reading or a pro

longed reading, the PTCR is faulty and must be replaced.

11. HEAT STRIP

Check the heat strip for continuity across the outside termi-

nals at the heat strip plug. If the circuit is open (no continu-

ity) the fuse link limit or heater element may be defective.

When the Comfort Control Center is set to operate the heat

strip the fan will operate in the low speed only the Auto fan

mode.

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Loading...

Loading...