2

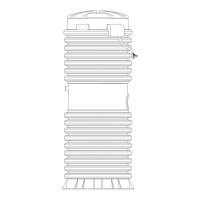

Environment One Grinder Pump Feature Identication

1. GRINDER PUMP BASIN – Fiberglass Reinforced Polyester (FRP)

2. ACCESSWAY COVER – High density polyethylene (HDPE)

3. ELECTRICAL QUICK DISCONNECT (EQD) – Cable from pump core terminates here.

4. POWER AND ALARM CABLE – Circuits to be installed in accordance with local codes.

5. ALARM PANEL – NEMA 4X enclosure. Equipped with circuit breakers. Locate according to local

codes.

6. ALARM DEVICE – Every installation is to have an alarm device to alert the homeowner of a

potential malfunction. Visual devices should be placed in very conspicuous locations.

7. INLET – 4” EPDM grommet (4.5” ID). For DWV pipe.

8. WET WELL VENT – 2.0” tank vent, supplied by factory in units with accessways.

9. GRAVITY SERVICE LINE – 4” DWV, (4.5 OD). Supplied by others.

9a. STUB-OUT – 4” X 5’ Long watertight stub-out, to be installed at time of burial unless the gravity

service line is connected during installation. Supplied by others.

10. DISCHARGE VALVE – 1-1/4” Female pipe thread.

11. DISCHARGE LINE – 1-1/4” Nominal pipe size. Supplied by others.

12. BEDDING MATERIAL – 6” minimum depth, round aggregate, (gravel). Supplied by others.

13. FINISHED GRADE – Grade line to be 1 to 4 inches below removable lid and slope away from

the station.

14. CONDUIT – 1” or 1-1/4”, material and burial depth as required per national and local codes.

Conduit must enter panel from bottom and be sealed per NEC section 300.5 & 300.7. Supplied by

others.

Loading...

Loading...