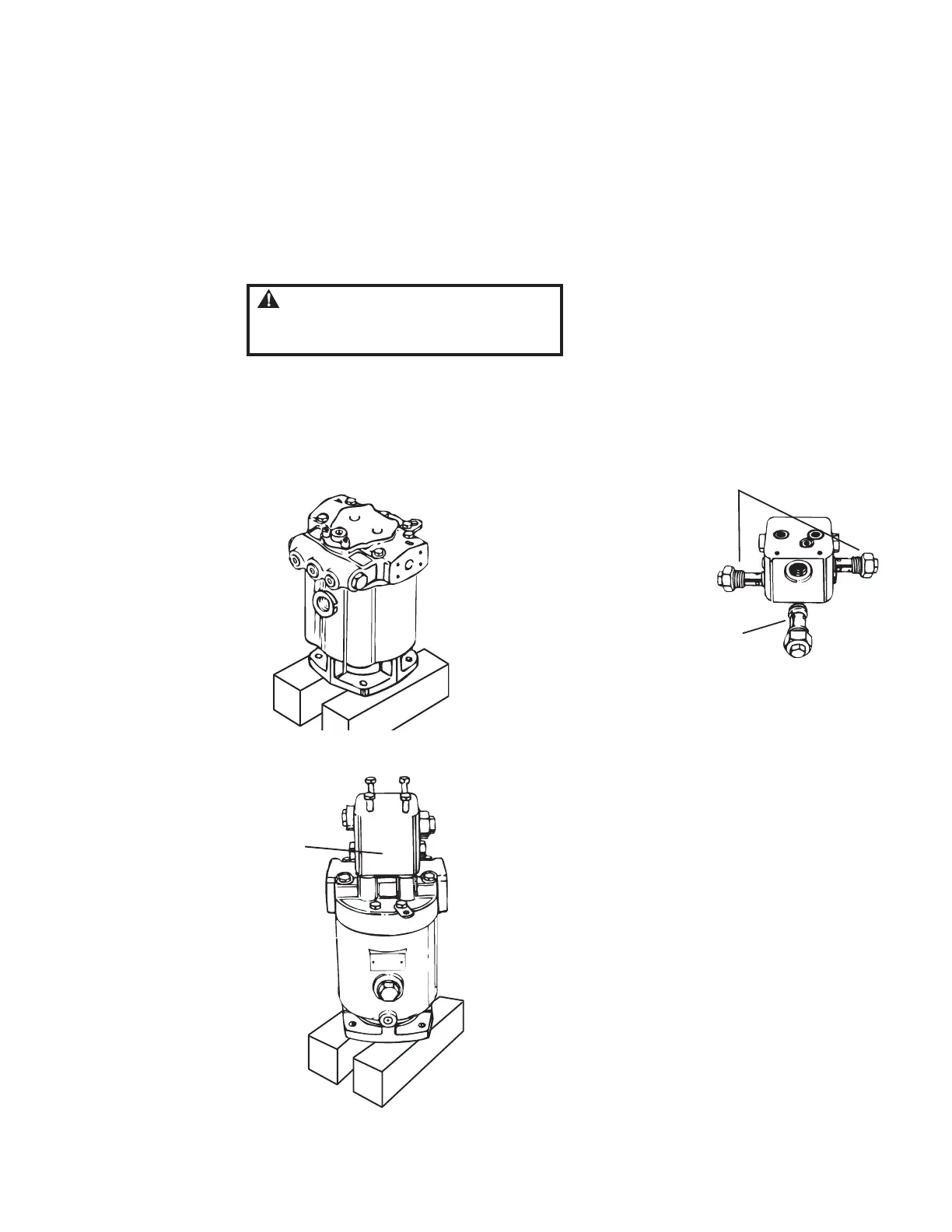

4. Using a 1-3/8 in. hex wrench,

remove the low pressure relief

valve cartridge.

Note: The low pressure relief

valve doesn’t have back-up

rings. There is only one O-ring

in the lower groove.

5. Using a 1-3/8 in. hex wrench,

remove the two high pressure

relief valves from valve block.

Note: The high pressure

relief valves have two white

back-up rings and one O-ring in

the lower groove.

High and low pressure relief

settings are preset at the

factory. Stamping on cartridge

identifies setting.

See examples.

Disassembly

Valve Block/

Integral Shuttle End

Cover

1. There are two types of Series

1 hydrostatic motors. If your

motor has an integral shuttle

and low pressure relief valve,

go to step 14 on page 16. If

you have a motor with a valve

block, continue with step 2.

Motors with Valve Block

Disassembly

Seal all open ports. Thoroughly clean exterior of motor before disassembly.

Cleanliness is extremely important when repairing a hydrostatic pump or motor. Work in a clean area, as the level of cleanliness maintained when

repairing the unit may affect performance. After washing the parts with clean solvent, blow dry the parts with filtered, moisture free air. Inspect all mating

surfaces. Replace all damaged parts. Do not use grit paper, files or grinders on finished parts.

Whenever a unit is disassembled, it is a good service policy to replace all seals. Lubricate the seals with petroleum jelly. Use only clean, recommended oil

when assembling the unit. See Hydrostatic Fluid Recommendations on page 28-29 or

publication No. 03-401 & 03-405 for recommended fluids.

CAUTION: Disconnect or disable all

electrical or mechanical power to the pump before

beginning work.

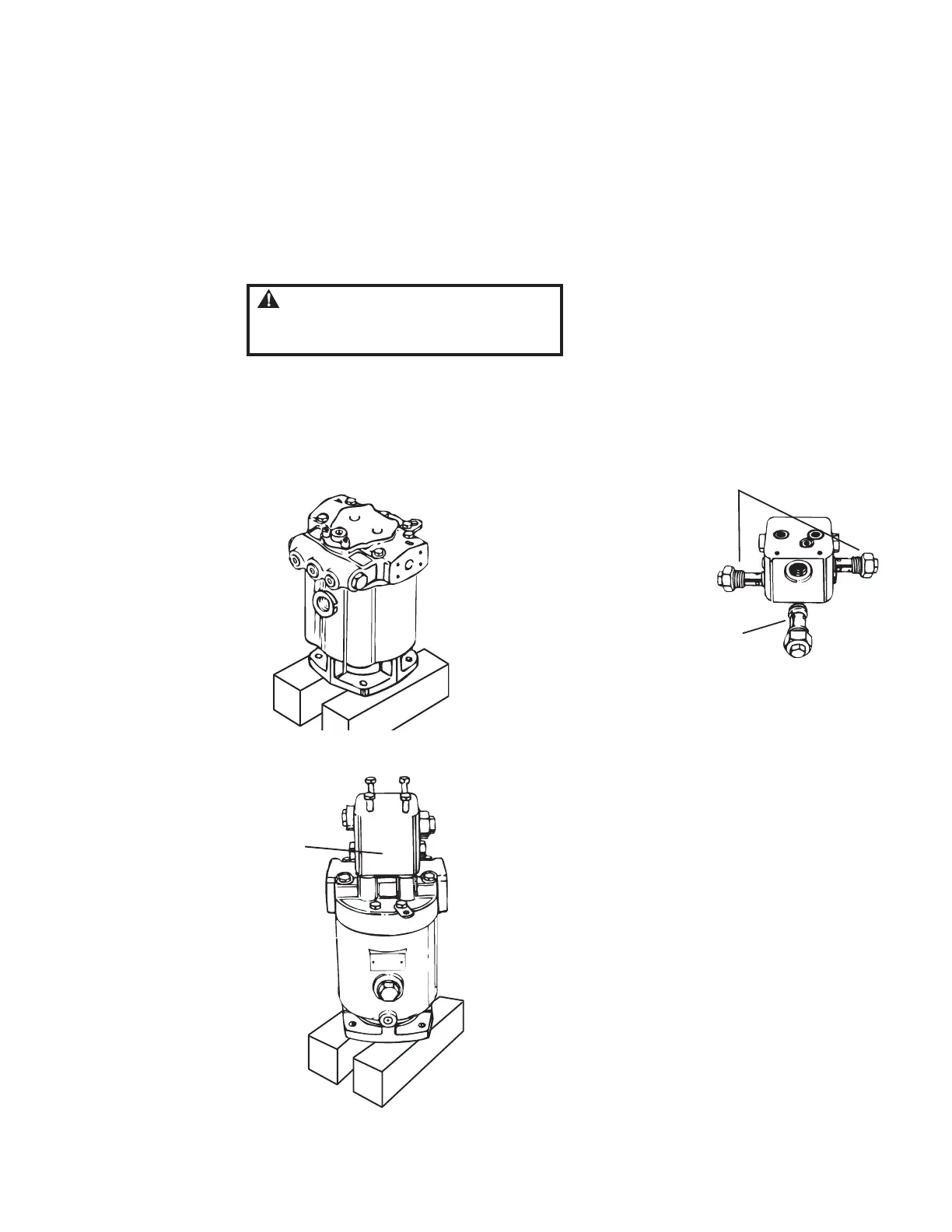

2. Position the motor on its

mounting flange as shown.

Loosen all the relief valves

and plugs in the valve block.

Remove the four bolts that

hold the valve block to the

motor. Then remove the

valve block.

3. Remove O-rings and

back-up rings from

mounting face of

valve block.

Loading...

Loading...