Storage

Transformers that will not be placed in service immediately

should be stored with terminal compartment doors closed

and sealed to prevent damage to bushings or other

attachments.

Quality standards

ISO 9001 certified quality management system

Installation

Installation location

The transformer must be located to meet applicable fire

codes. For indoor installations, the installation location must

meet the requirements of the National Electrical Code

(NEC

®

) with sufficient space requirements and proper over-

current protection as specified by the listing body that has

jurisdiction over the installation.

These pad-mounted transformers are built to operate

at altitudes up to 3300 feet at 30 °C average and 40 °C

maximum ambient, unless otherwise specified. Before

operating a standard transformer at higher altitudes, contact

your Eaton representative.

Mounting the transformer

The transformer should be mounted on a level concrete

pad. The pad should be strong enough to support the

weight of the transformer. The site must be adequately

prepared to prevent the transformer from tilting beyond two

degrees from horizontal.

Tilting beyond two degrees may cause internal components

to come out of the oil and/or cables to mechanically stress

the bushings and bushing gaskets. Excessive tilt (beyond

two degrees) can result in a lower dielectric strength for the

transformer than the basic insulation level (BIL) listed on the

nameplate. Reduced BIL can result in an internal dielectric

breakdown with a risk of explosion, tank rupture, or fire.

To maintain full cabinet security, the transformer tank and

cabinet base have provisions for installing cleats to secure

transformer to pad. If gaps still exist between the cabinet

and pad after cleating the cabinet, the installation will not

provide the security needed to prevent tampering by the

public. Add a permanent mortar seal to fill the gaps.

Pre-service inspection (exterior)

New transformers, or transformers which are being

activated after a period of storage, should be thoroughly

inspected before being connected to the power distribution

system to identify damage which may have occurred during

storage.

1. The transformer exterior should be inspected for nicks,

dents, and scratches. Repair damage to weather-

resistant finishes promptly.

2. The tank cover and manhole/handhole cover seals

and all gaskets or seals at bushings, gauges, fuses,

operating devices, etc., should be inspected for

evidence of insulating liquid seepage. Repair leaking

or improperly tightened gaskets and seals before the

transformer is placed in service.

3. Under normal conditions, the transformer leaves the

factory with a slight positive pressure in the tank

over the oil. However, due to changes in atmospheric

conditions, the unit may arrive under vacuum (negative

pressure). This is itself is not cause for concern, however

continued absence of either negative or positive

pressure may indicate a leak at a gasket seal or tank

seam, and require further investigation. To leak test

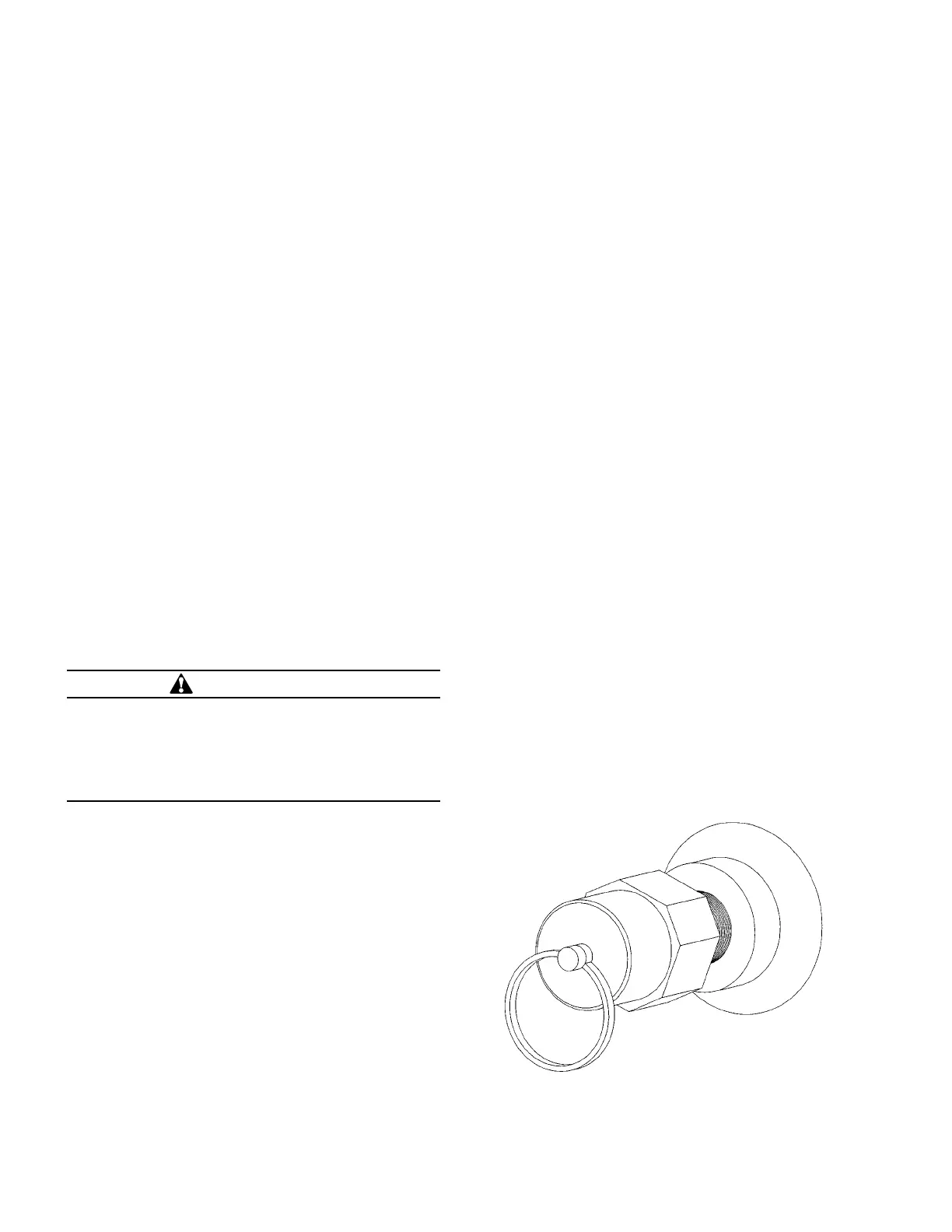

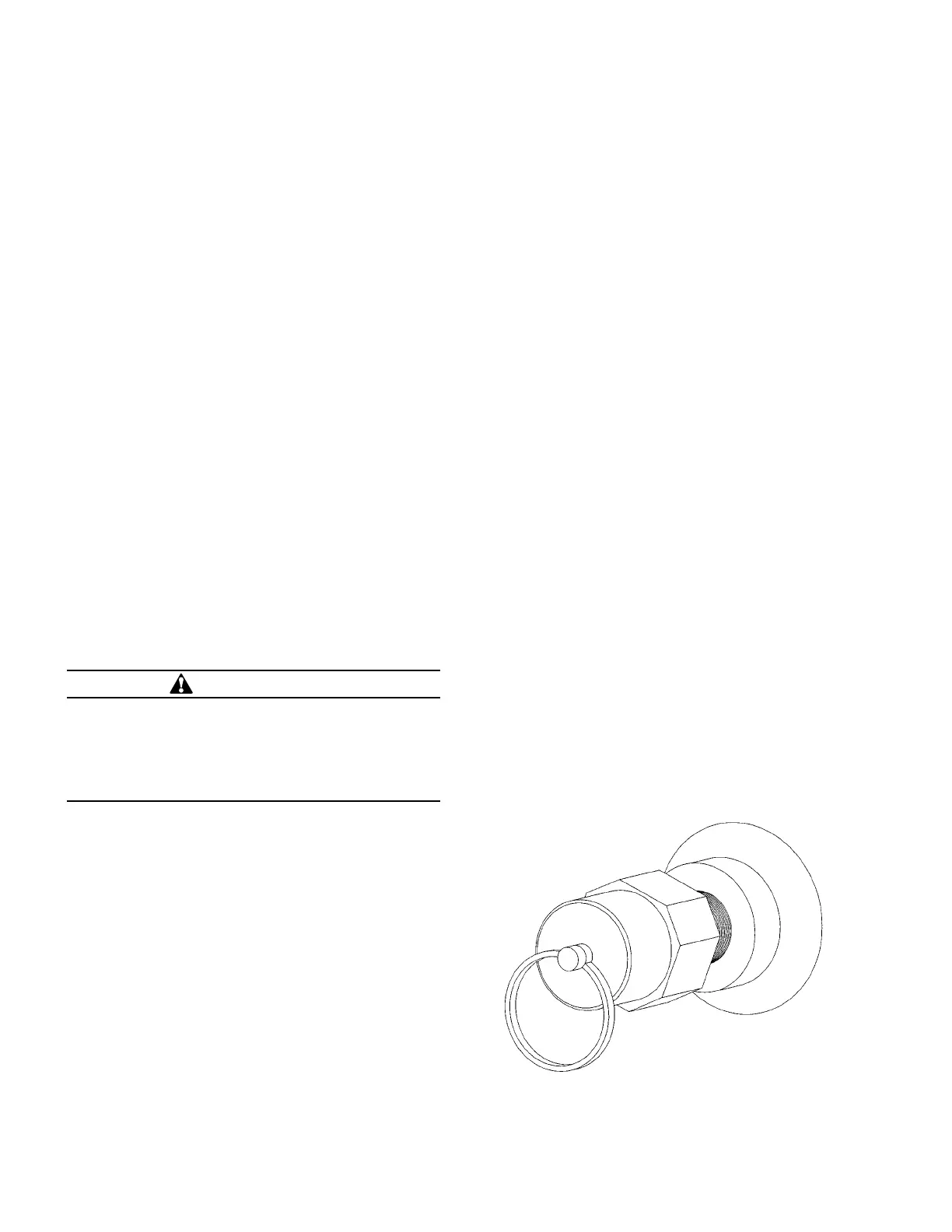

transformer, remove the pressure relief valve (see Figure

1) and pressurize the headspace to ensure that there are

no leaks. The test pressure should not exceed 7 psig.

The established pressure should be maintained for at

least four hours to ensure that all the seals are proper.

Figure 1. Pressure relief valve.

WARNING

Fire Hazard. Non-level installation of transformer

can result in fire and cause severe personal injury or

death. Prepare transformer installation site such that

transformer does not tilt more than two (2.0) degrees

from horizontal while the transformer is in service at

the site.

2 Three-phase pad-mounted compartmental type installation and maintenance instructions MN202001EN August 2015

Loading...

Loading...