Figure 3-10 General Partial Cross-Sectional View (Shown

in Closed Position) (not specific to any family/frame)

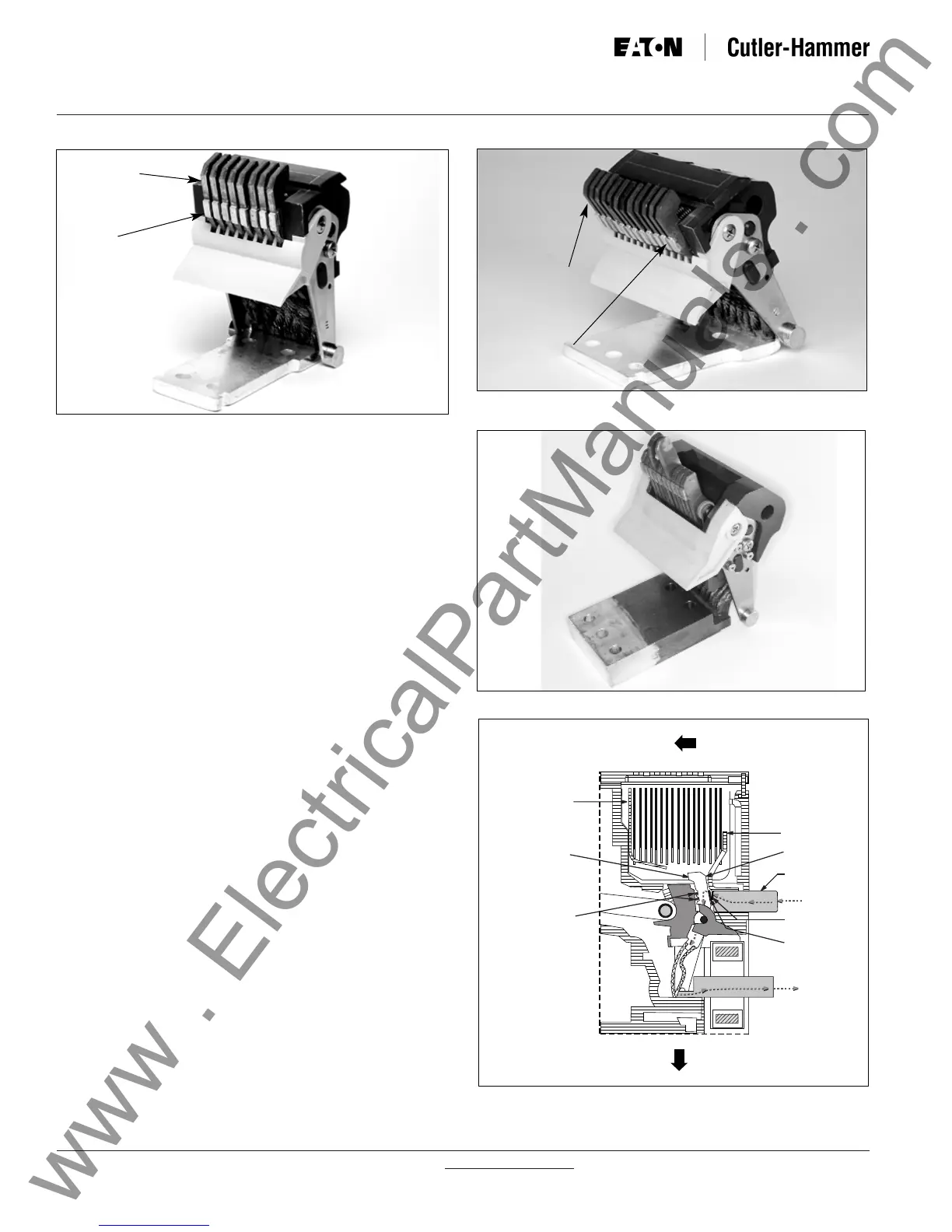

3-3.1 PRIMARY MOVING CONTACTS

Depending upon the frame size, each primary moving

contact assembly is comprised of multiple individual

copper contact fingers connected to the load conductor

through flexible braided connectors (Figure 3-8). Two

flexible connectors are used to connect each finger to

the load conductor. The number of fingers used

depends upon the circuit breaker’s continuous and

short-circuit current ratings (Figures 3-8 and 3-9). On

some ratings fingers are removed and replaced with

spacers.

The single contact finger performs both the main and

arcing contact functions on different parts of the same

finger (Figure 3-7). A highly conductive alloy pad is part

of the contact finger and functions as the moving main

contact, and is called the “Heel.” The tip of the same

contact finger functions as the moving arcing contact,

and is called the “Toe.”

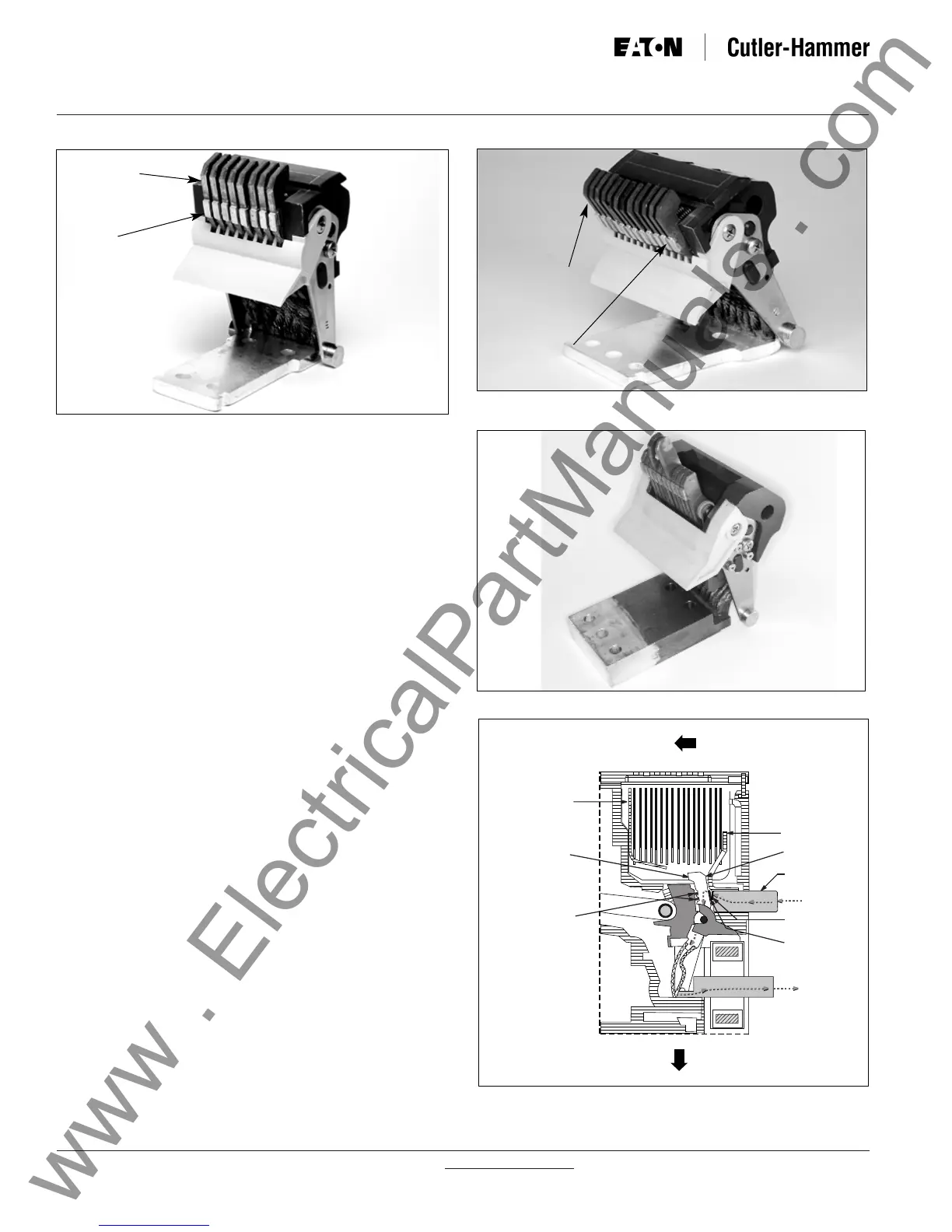

In addition to the contact finger information given above,

DSX (MDSX) utililize an inner and outer carriage design

to facilitate a fast opening blow open contact structure

(Figure 3-9a). The contact fingers mounted in the inner

contact carrier can move independently from both the

outer carrier and the opening mechanism in the breaker.

This independence is the core design feature of its fast

opening blow open contact structure.

Figure 3-8 Narrow Frame (8-finger) Moving Conductor

Assembly

“Heel”

(Main Contact)

“Toe”

(Arcing Contact)

“Toe”

(Arcing Contact)

“Heel”

(Main Contact)

Figure 3-9a MDSX Moving Contact Assembly

Loading...

Loading...