16

Instructional Booklet IB02102006E

Effective May 2011

Type MVS (previously WLI)

metal-enclosed switchgear—

4.76 kV, 15.0 kV, 27.0 kV, and 38.0 kV

EATON CORPORATION www.eaton.com

Operation

Mechanical safety interlocks

The MVS switch is equipped with switch interlocks and door inter-

locks, as well as provisions for padlocking in either the “Open” or the

“Closed” position.

WARNING

DEFEATING OR DISENGAGING SAFETy INTERLOCKS ON AN MVS SWITCH

THAT IS CONNECTED TO A POWER SOURCE MAy RESULT IN PROPERTy

DAMAGE, BODILy INJURy, OR DEATH.

DO NOT DEFEAT OR DISENGAGE ANy SAFETy INTERLOCKS.

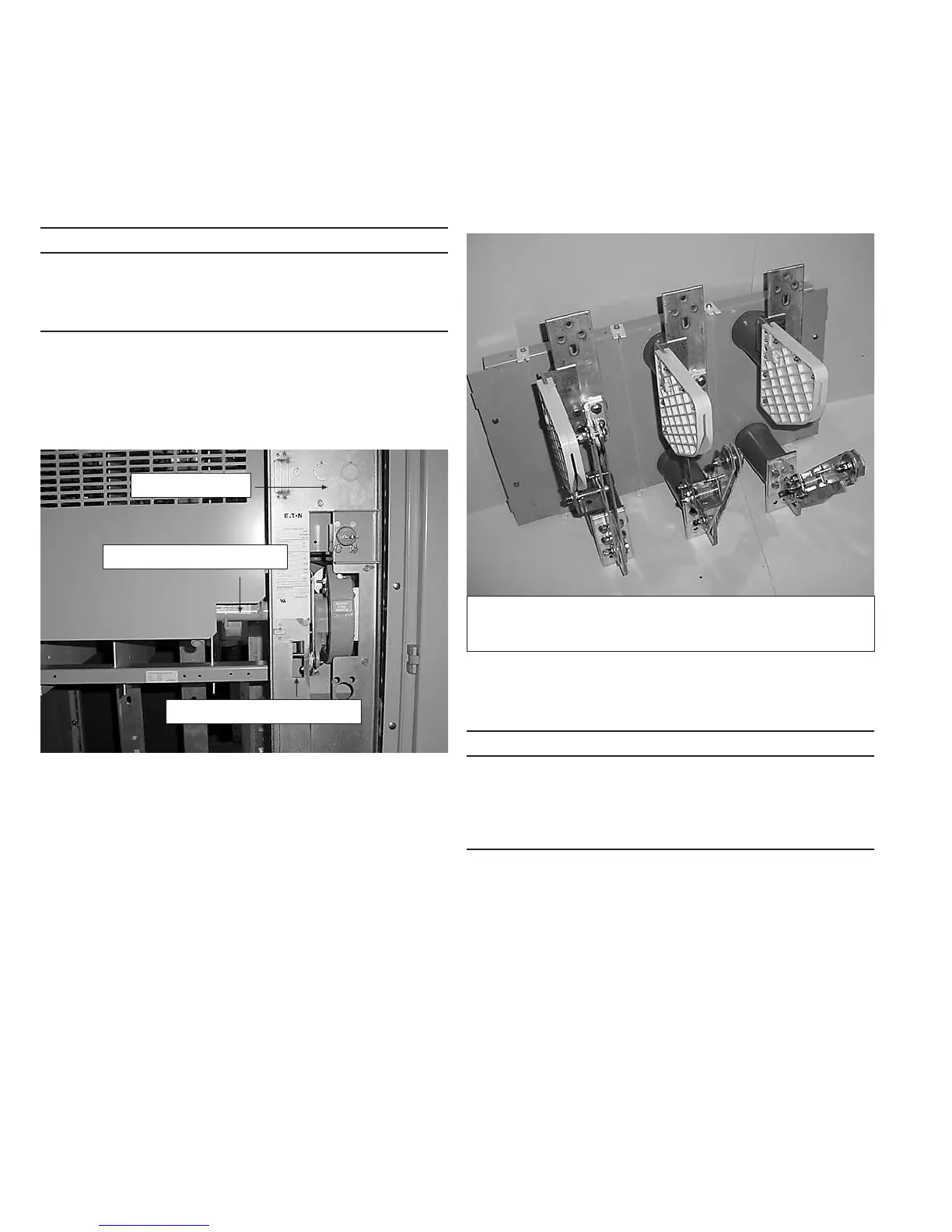

Switch interlock

The switch interlock prevents inadvertent closure of the switch if the

enclosure door is open. When the door is closed, the pointed latch

lug welded to the inside of the door causes the safety latch to move

out of the blocking position (see Figure 21).

Figure 21. Door/Switch Mechanism and Shaft Interlock

Locations

Door interlock

The door interlock prevents the door of the enclosure from being

opened when the switch is “Closed.” When the switch is “Closed,” a

cam welded to the operating shaft engages a bracket welded to the

inside of the switch door, preventing the door from being opened

(see Figure 21).

Key interlocking

Key interlocks are supplied when specified. Certain MVS switchgear

configurations require key interlocks and they are therefore included.

Standard schemes are available for locking the switch in the “Open”

or the “Closed” position, as well as locking the main door closed.

Numerous other schemes are available for special requirements that

can coordinate with upstream or downstream devices supplied by

Eaton or other equipment.

Switch operation

The quick-make mechanism provides power to overcome blowout

forces that occur if the switch is “Closed” into a fault. However, these

forces are not transmitted to the operating handle because it is

not rigidly connected to the blades. Therefore, the switch can be

safely closed under short-circuit conditions within its fault-close rating.

Mechanism Cover

Door/Switch Shaft Interlock

Door/Switch Mechanism Interlock

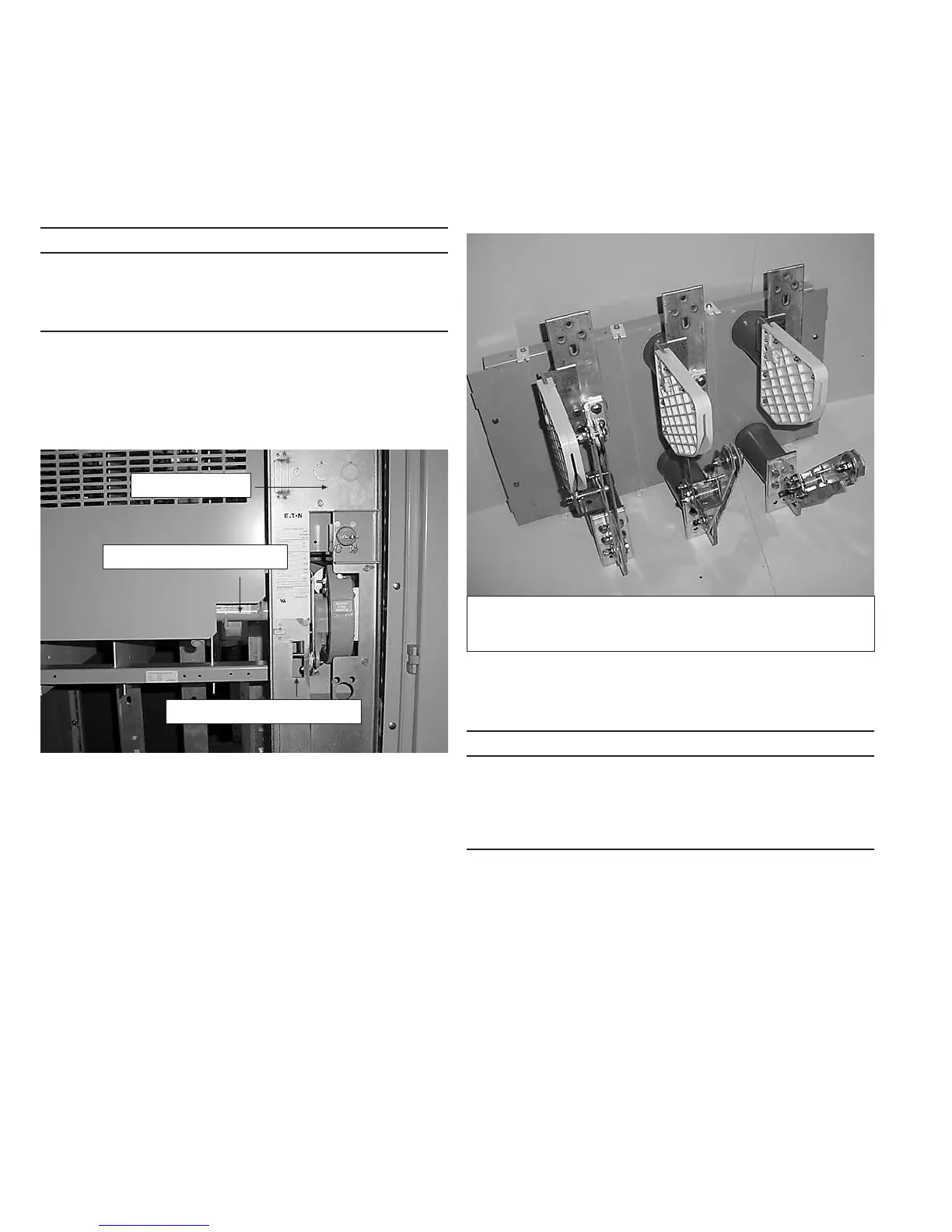

Load interruption is accomplished by a flicker blade and engaging

contact fingers located inside a DE-IONT arc chute. On opening the

switch, the main blades open first and all current is shunted through

the spring-loaded flicker blades. Further travel of the main blades

causes the flicker blades to snap out of their contact fingers where

associated arcing takes place within the arc chutes. See Figure 22

for the sequence of operation.

Figure 22. Main and Flicker Blade Operation

Fuse replacement

WARNING

WHEN ACCESSING FUSES, FAILURE TO ENSURE THAT THE FUSES ARE

DE-ENERGIzED MAy RESULT IN EQUIPMENT DAMAGE, BODILy INJURy,

OR DEATH.

MAKE SURE THAT ALL POWER SOURCES ARE DE-ENERGIzED BEFORE

ATTEMPTING TO ACCESS THE FUSES.

Step 1: All upstream devices that could energize the fuse should be

opened, padlocked, and tagged so that inadvertent closure cannot

create a hazard.

Step 2: The MVS switch should be in the “Open” position. This is

accomplished by rotating the operating handle downward.

Step 3: Before opening the door, look through a viewing window

to visually verify that all blades are disengaged from their break jaws.

Step 4: After opening the door, an appropriate medium voltage

sensing device should be used to determine if voltage is present.

Step 5: If no voltage is present, a suitable grounding device should

be attached to the fuse terminals to discharge any static charge and

ensure that the fuse terminals remain at ground potential.

Step 6: The fuses are removed by loosening the plastic hand

knobs and removing the locking bars. The fuses are then free to be

removed. When the fuses are re-installed, the hand knobs should be

retightened hand tight.

Left Pole: Main Blade and Flicker Blade Colsed.

Center Pole: Main Blade Open, Flicker Blade Closed.

Right Pole: Main Blade and Flicker Blade Open.

Loading...

Loading...