Arc-Strangler loadbreaking device with NX

®

fusing

NX

®

full-range current-limiting fuses up to 15.5 kV can

be ordered with an integral Arc-Strangler

®

loadbreaking

device. These in-air devices are mounted on the faceplate

of the transformer. The Arc-Strangler device has the same

operating characteristics as the basic NX clip-style fuse,

along with loadbreaking capabilities.

The Arc-Strangler loadbreaking device is a spring-loaded

sliding sleeve that extinguishes the arc drawn between the

mounting contacts and the fuse conductor when the fuse

is opened while load current is flowing. All magnitudes

of current through the continuous current rating of the

fuse can be interrupted positively and safely under proper

conditions. A pull-ring at the top of the fuse assembly (for

hotstick operation) and a hinge at the bottom complete the

loadbreak device.

Arc-Strangler switchblades

Switchblades with integral Arc-Strangler loadbreaking

devices are available for use in NX type fuse mountings.

Arc-Strangler switchblades are designed to break load

current only (up to 200 A) and do not incorporate a fuse of

any type for overload or fault interruption.

Surge arresters

Surge arresters are used in three-phase pad-mounted

transformers to protect underground distribution equipment

and cable from overvoltage surges. During steady state

conditions, line-to-ground voltage is applied continuously

across the arrester terminals. When surges occur, the

arrester immediately limits the overvoltage to the required

protective level by conducting the surge current to ground.

Upon passage of the surge, the arrester returns to its initial

state, conducting minimal leakage current.

Surge arresters should be installed only on systems where

the power frequency voltage at the arrester does not

exceed published maximum continuous operating voltage

(MCOV) values.

The transformer should not be tested (impulse or applied

potential) with the arrester connected. If connected during

impulse tests, the arrester will clamp the discharge voltage

applied by the test equipment. If the arrester is connected

to the transformer during an applied potential test, there is

a possibility that the arrester will be damaged. Disconnect

surge arresters before tests are performed on the

transformer. Arresters should be reconnected immediately

after tests are completed.

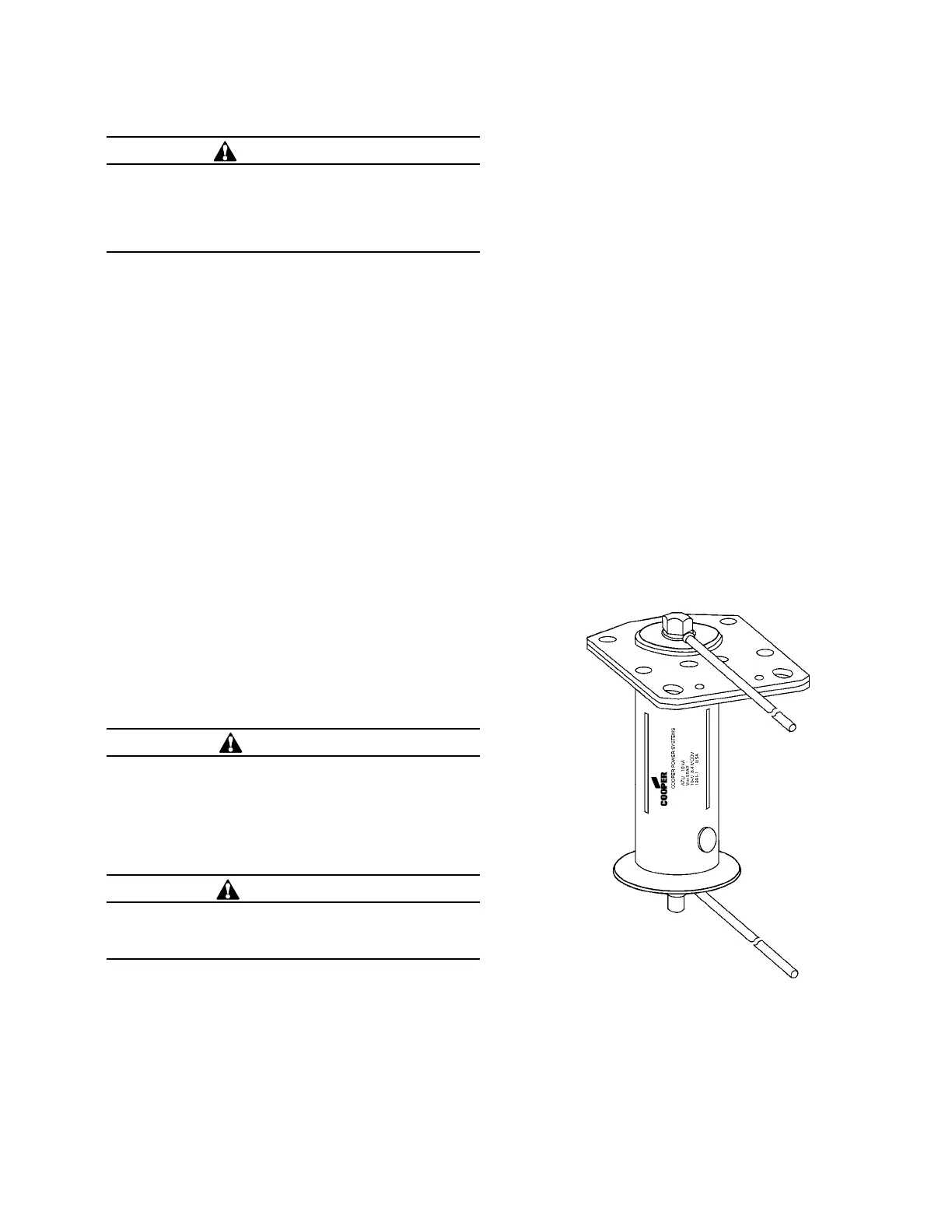

Under-oil MOV arrester

Eaton’s Cooper Power series heavy-duty distribution-class

under-oil MOV arrester is designed to be mounted inside

the transformer tank (see Figure 25). Internal, under-oil

mounting of the arrester prevents shortened arrester life

due to surface contamination, wildlife damage, vandalism,

or moisture ingress.

Under-oil arresters are designed to operate when

submerged in oil. It is recommended that the average oil

temperature not exceed 90 °C and that the maximum oil

temperature not exceed 125 °C.

Figure 25. Heavy-duty distribution-class under-oil MOV

arrester.

WARNING

Hazardous voltage. Can cause severe injury, death, or

damage to equipment. Depending on configuration,

Arc-Strangler fuses or switchblades may be energized

even when in the “open” position. Refer to catalog

section 240-60 for further information.

WARNING

Hazardous voltage. Can cause severe injury, death, or

damage to equipment. De-energize transformer from a

remote upstream source before servicing or operating

surge arresters or disconnect switches. Check that all

transformer terminals and bushings have zero voltage.

Ground transformer following industry accepted safe

grounding practices.

CAUTION

Excessive test voltage can damage surge arresters.

Disconnect surge arresters before running impulse or

applied potential tests on the transformer.

17Three-phase pad-mounted compartmental type installation and maintenance instructions MN202001EN August 2015

Loading...

Loading...