Replacing

Replacement draw lead type bushings can be installed by

following the removal procedure in reverse order. Clamp

bolts should be tightened as specified in Table 1.

The gasket under the bushing mounting flange and the

top gasket should be new or in good condition to ensure a

positive seal. The gasket mating surfaces must be clean and

smooth.

The threaded stud is keyed to the inside of the bushing to

prevent rotation while the terminal cap is being tightened. It

is important to have the threaded stud correctly seated. This

can be accomplished by pulling the stud up and turning it

until it is aligned and seated.

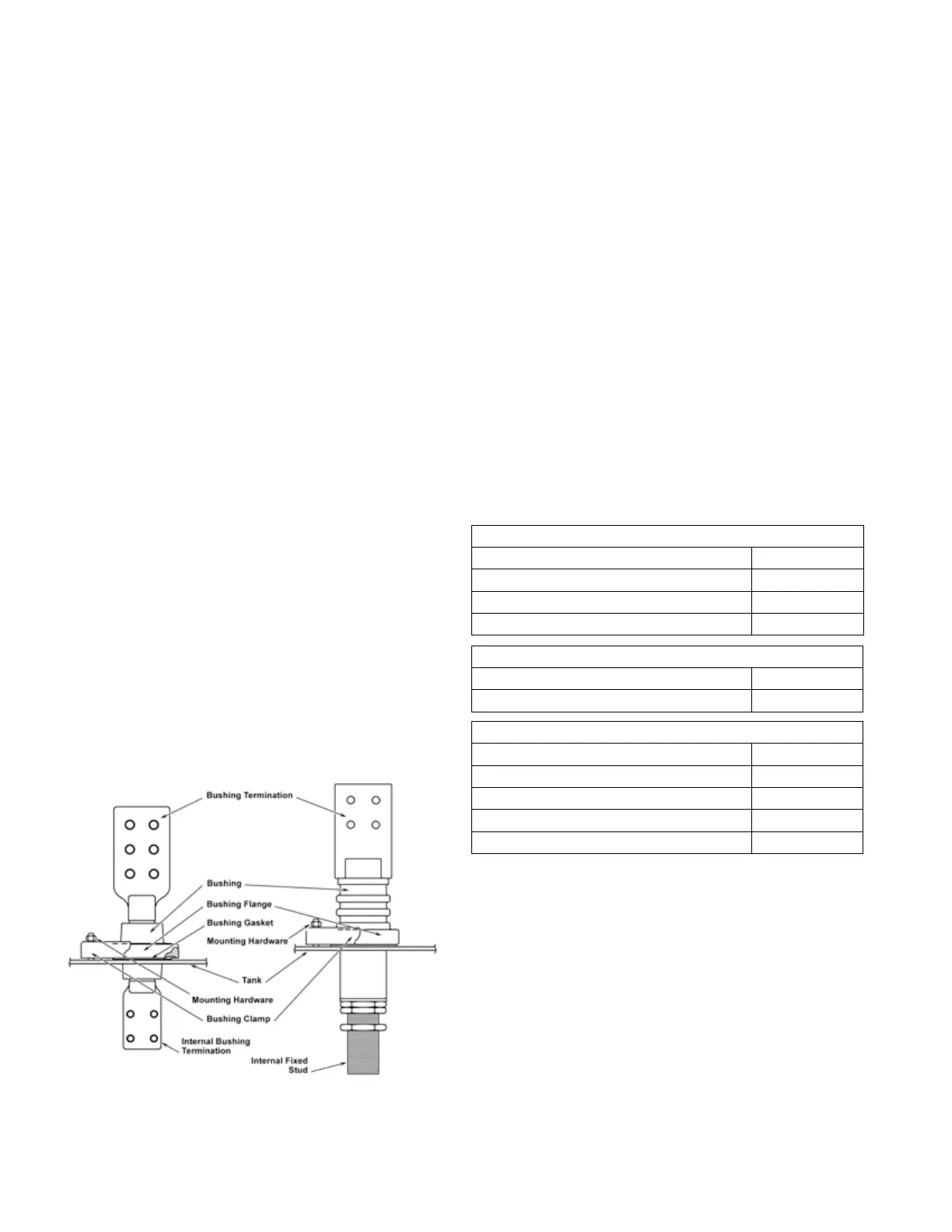

Removing and replacing fixed stud or spade type

bushings

Removing

1. Remove inspection cover (manhole) nearest to bushing,

only after all precautions outlined under "Removing and

Replacing Bushings" have been taken.

2. To remove the inspection cover:

A. Thoroughly clean the cover. Remove all dirt, grease

and moisture.

B. Release and remove cover bolts.

C. Remove the cover. Lift vertically to prevent damage

to bolt or cover gaskets.

3. Unbolt the connections–usually flexible straps–from the

bottom end of the bushing stud.

4. Remove the bushing mounting clamp nuts at the tank

to release the mounting clamp plate and free the

bushing for removal.

5. Remove the bushing.

Replacing

Replacement bushings can be installed by following the

removal procedure in reverse order. Clamp bolts should be

tightened as specified in Table 1.

The gasket under the bushing mounting flange should be

new or in good condition, and the gasket mating surfaces

must be clean and smooth.

After installing and connecting the new bushing, replace

the inspection opening cover, making certain the gasket is

in good condition and the gasket mating surfaces are clean

and smooth.

Return to the transformer any liquid removed and check for

the correct level.

A brief pressure test of the transformer at 5 psig to confirm

the integrity of the seals around all openings above the

liquid level is recommended. A solution of soap and water

will give indication of a leak by the presence of bubbles.

Bushing Clamps

4-hole Aluminum Cast Bushing Clamps 70-80 in.-lbs.

Molded Tri-Clamp Bushing 40-60 in.-lbs.

All other 3- & 4-hole Bushing Clamps 40-60 in.-lbs.

2-hole Bushing Clamps 55-65 in.-lbs.

TABLE 1 Torque Values

Internal Spade Bushings

1/2" Steel (Grade 8) 50 ft.-lbs.

3/8" Steel (Grade 8) 50 ft.-lbs.

Internal Stud Bushings

3/8"-16 Brass Nuts 16 ft.-lbs.

5/8"-11 Aluminum Nuts 60 ft.-lbs.

5/8"-11 Brass Nuts 75 ft.-lbs.

1"-14 Brass Nuts 121 ft.-lbs.

Bushing Lead Block, ½” Steel Hardware 110 ft.-lbs.

Figure 12. Fixed stud and spade type bushings.

12 SubStation tranSformer inStallation and partS replacement information MN202002EN JUNE 2016

Loading...

Loading...