14

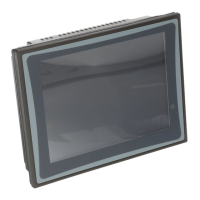

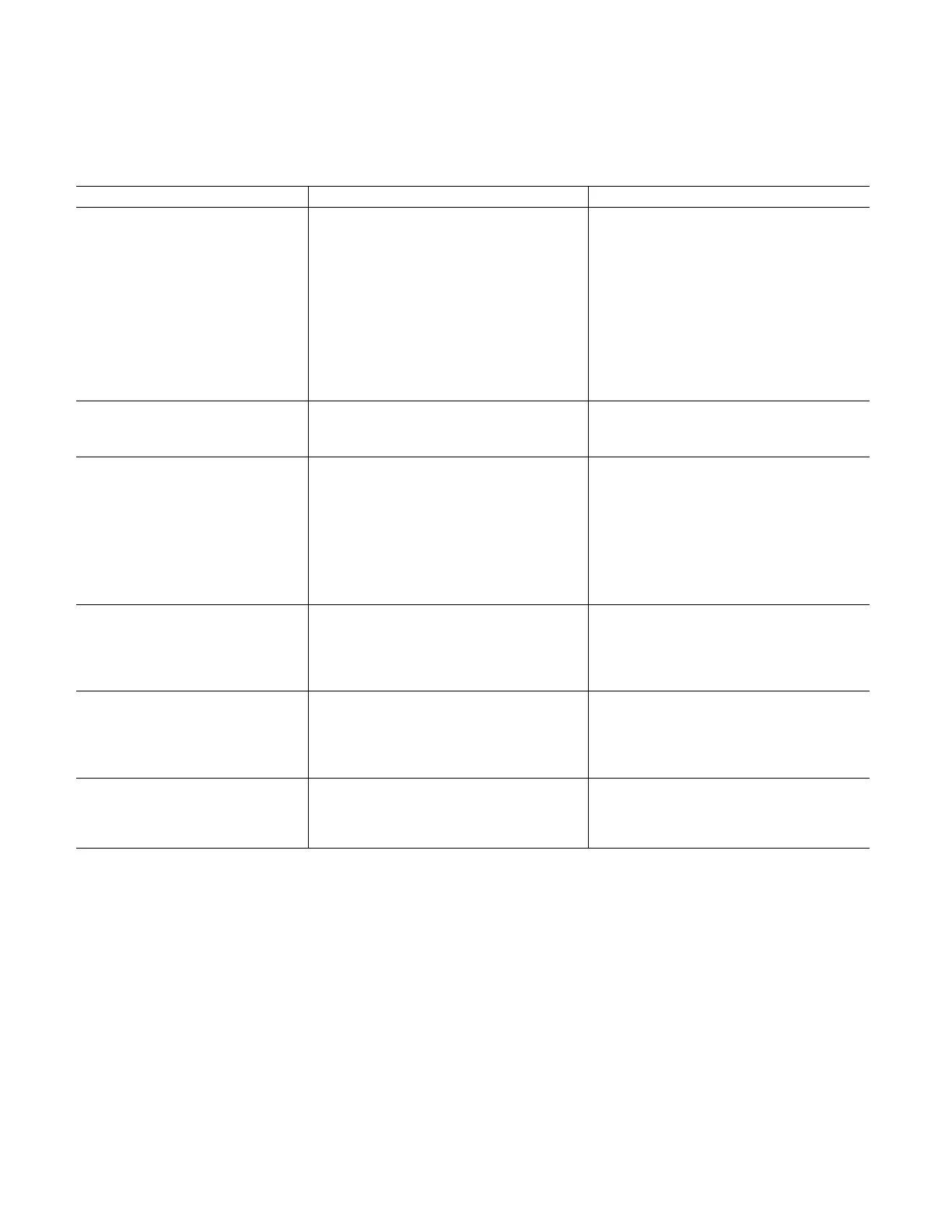

F. Troubleshooting

Table 4 lists the difficulties which may be experienced with

the unit and hydraulic system. It indicates the cause and

remedy for each of the troubles listed. It should always be

remembered that pressure and delivery are factors which

are usually dependent upon each other. Adequate pressure

gage equipment and a thorough understanding of the

operation of the complete hydraulic system are essential to

diagnose improper operation.

TROUBLE

PROBABLE CAUSE REMEDY

Oil leads at either end of spool Defective O-rings in valve body

Broken springs

Bent spool

Foreign particles

Misalignment of operating linkage

Valve tank improperly torque

Replace O-rings.

Replace springs.

Replace with new section of same size

and type.

Clean system and valve,

Check linkage for binding condition.

Re-torque nuts to specified ratings.

Detent type spools will not stay in

detent position

Worn detent barrel

Weak or broken detent spring

Replace detent barrel.

Replace detent spring.

No motion, slow or jerky action of

hydraulic system

Relief valve not properly set, or stuck in

base and/or worn

Dirt or foreign particles lodged between

relief valve control poppet and seat

Valve body cracked inside

Spool not moved to full stoke

Repair, clean and readjust.

Disassemble, clean and reassemble.

Replace valve section.

Check travel.

No relief valve action

(High Pressure)

Small particle of dirt plugging orifice in

relief valve sub-assembly

Relief valve sub-assembly installed

backwards.

Remove relief valve and check hole. If

blocked, clear hole.

Install properly.

Load will not hold Oil by-passing between spool and body

Oil by-passing piston in cylinder

Spool not centered

Replace valve.

Repair or replace cylinder.

Refer to above spool remedies.

Load drops when spool is moved

from neutral to a power position

Dirt or foreign particles lodged between

check valve poppet and seat.

Scored or sticking check valve poppet

Disassemble, clean and reassemble.

Replace poppet.

Table 4. Troubleshooting Chart

Loading...

Loading...