August 2015

Service Instructions

137463E Rev. D

4

Section 1: Introduction

Introduction

1�8 Actuator Weight

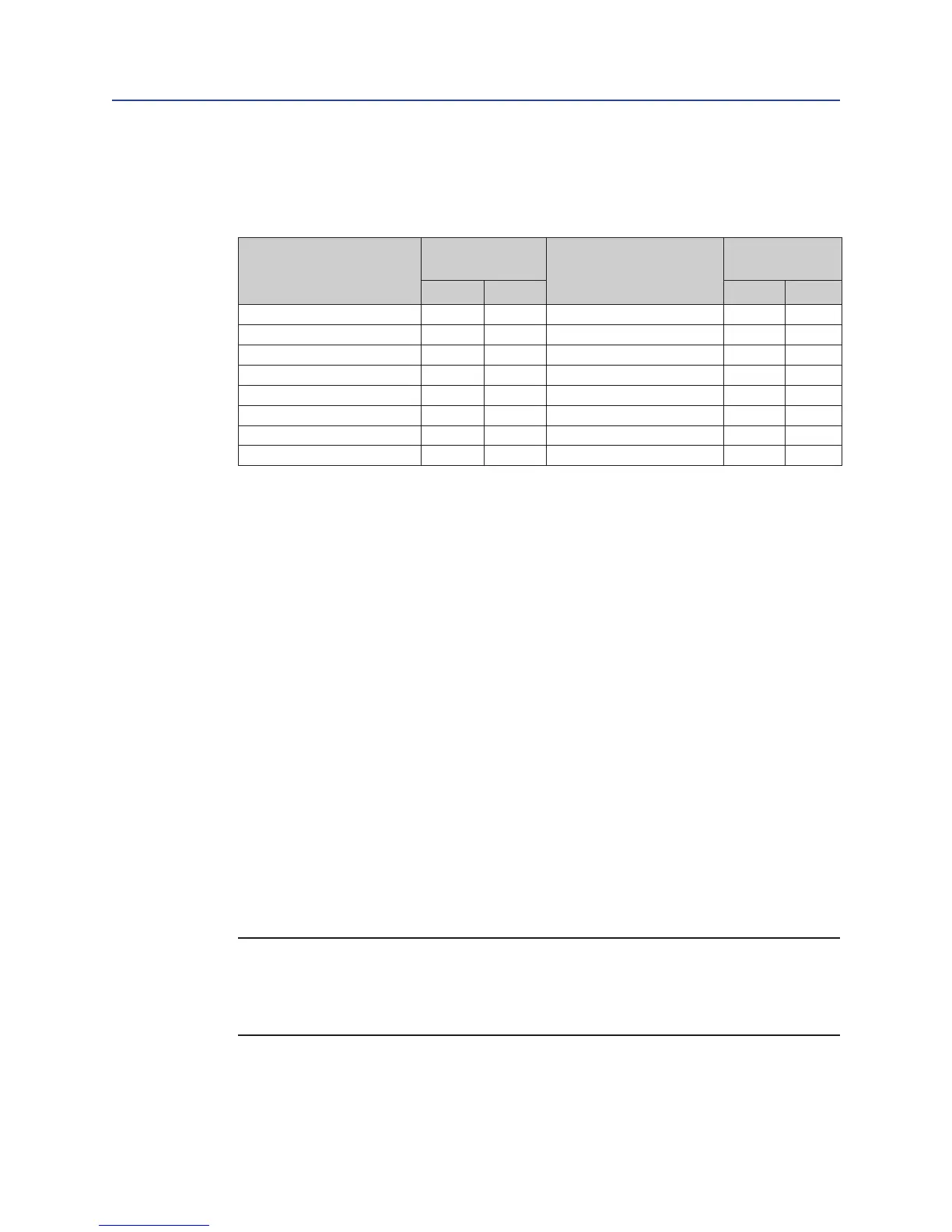

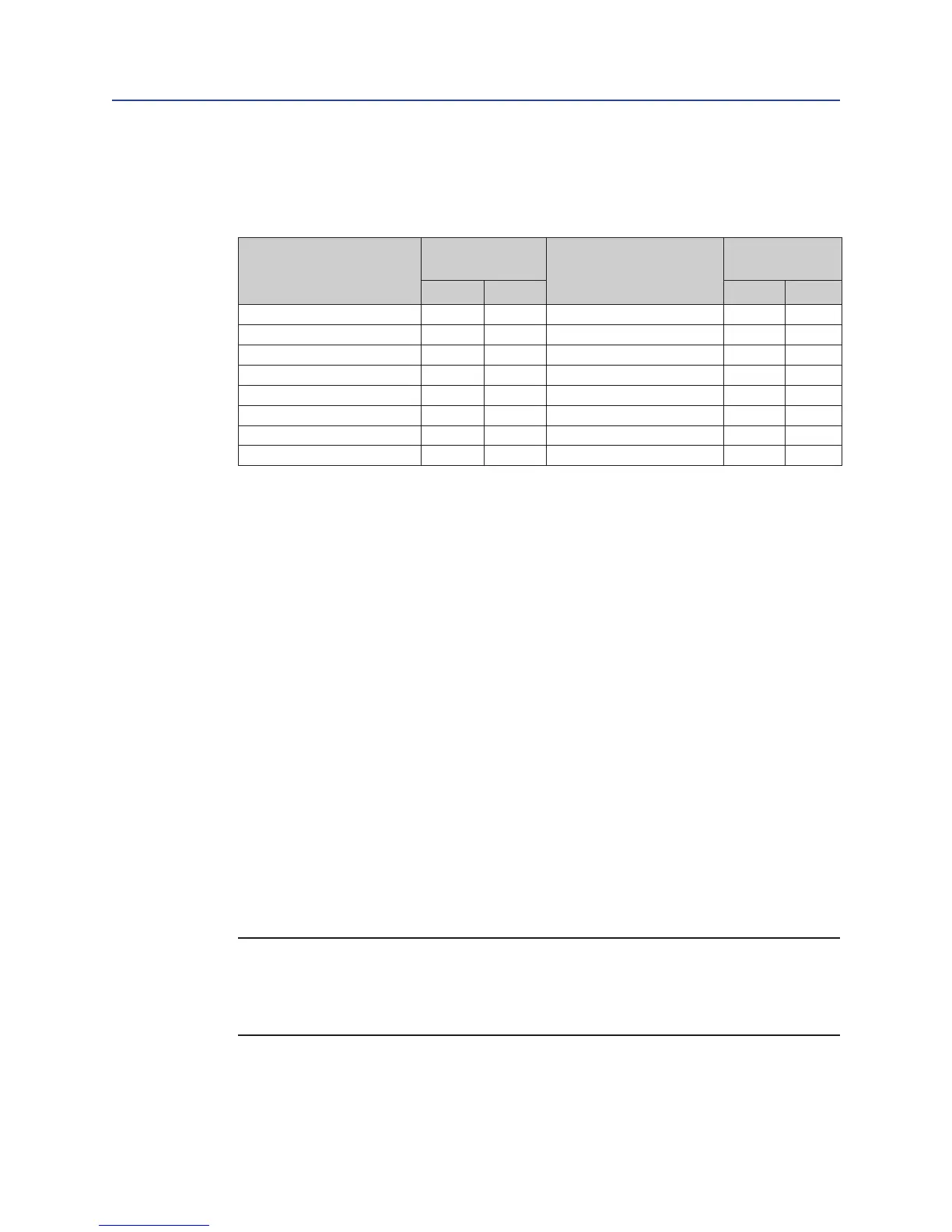

Table 2� Actuator Weight

Actuator Model

Approximate

Weight (2)

Actuator Model

Approximate

Weight (2)

LB KG LB KG

CBA730-SR40 (1) 158 71.7 CBA930-SR40 (1) 195 88.5

CBA730-SR60 (1) 160.5 72.8 CBA930-SR60 (1) 202 91.6

CBA730-SR80 (1) 163 73.9 CBA930-SR80 (1) 206.5 93.7

CBA730-SR100 (1) 164 74.4 CBA930-SR100 (1) 205 93.0

CBA830-SR40 (1) 180 81.6 CBA1030-SR40 (1) 220 99.8

CBA830-SR60 (1) 184.5 83.7 CBA1030-SR60 (1) 225.5 102.3

CBA830-SR80 (1) 188 85.3 CBA1030-SR80 (1) 233.5 105.9

CBA830-SR100 (1) 192.5 87.3

(1) When model has -M3HW add 8 pounds / 3.6 kilograms.

(2) Weight is for bare actuator without accessories or valve adaption.

1�9 Actuator Storage

For applications where the actuator is not placed into immediate service, it is

recommended that the actuator be cycled with regulated clean/dry pneumatic pressure

at least once per month. Indoor storage, if available, is recommended for all actuators.

Care should be taken to plug all open ports on actuator and controls to keep out foreign

particles and moisture. Actuators should not be stored in an atmosphere that is harmful to

resilient seals. Contact factory for extended storage period.

1�10 Actuator Installation

1.10.1 Since there are many valve and actuator combinations, it is not practical to include

detailed instructions for each type. Mountings are designed to be as simple as

possible to keep the guess work out of the installation.

1.10.2 Actuators that are shipped from the factory with the travel stops adjusted for

approximately ninety degree rotation. Generally, it is necessary to make slight

travel stop adjustments once the actuator is installed onto the valve. Refer to the

valve manufacturer's recommendations for specic requirements. When the valve

has internal stops, the actuator should be adjusted at the same points.

NOTE:

The actual "stopping" should be done by the actuator. If the valve does not have internal

stops, adjust the actuator to the full open position. Using this as a reference point, rotate

the valve closed and adjust to the valve manufacturer's specications for total rotation.

1.10.3 Good instrument practices are also recommended. Clean/dry regulated

pneumatic pressure is essential for long service life and satisfactory operation.

It should be noted that new pneumatic lines often have scale and other debris in

them and these lines should be purged of all foreign material.

Loading...

Loading...