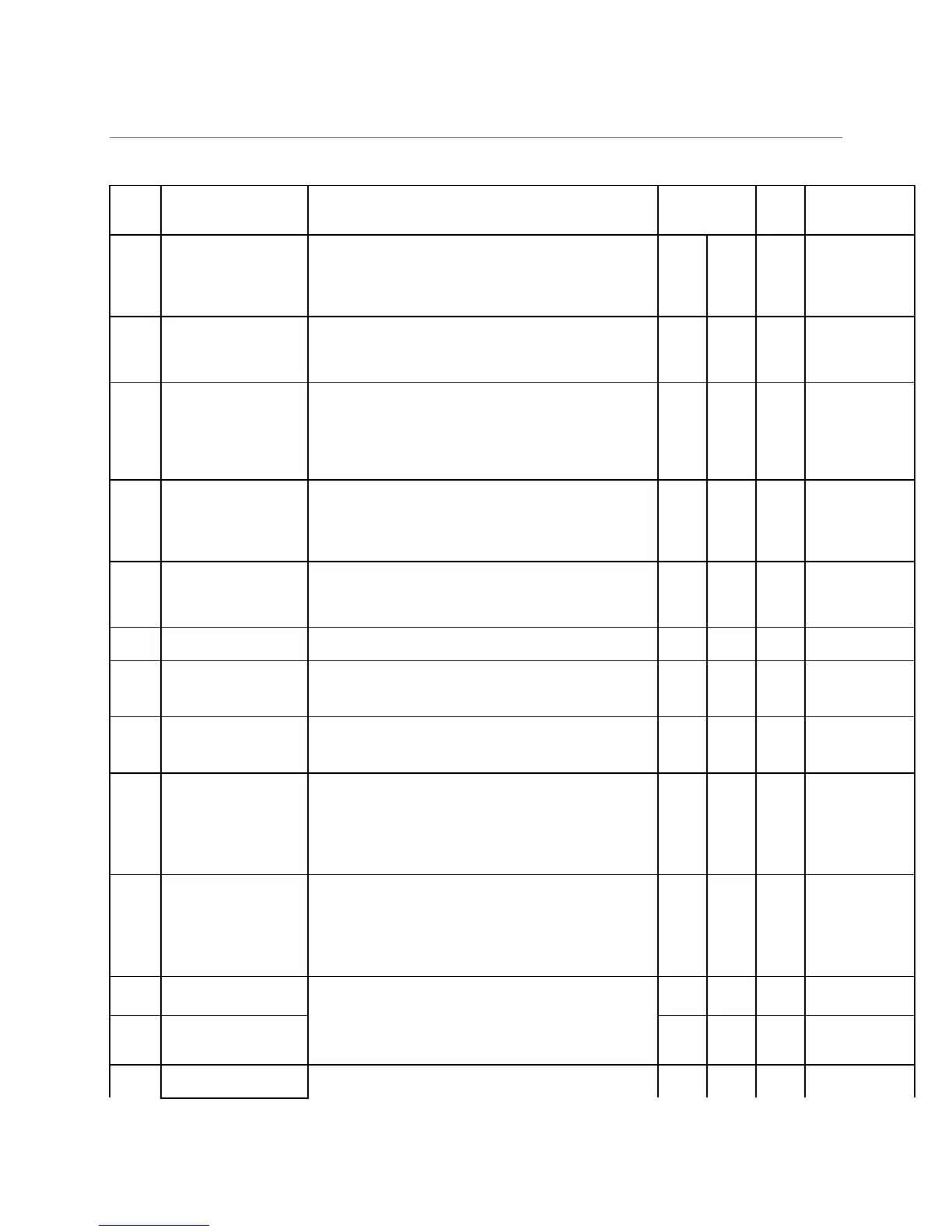

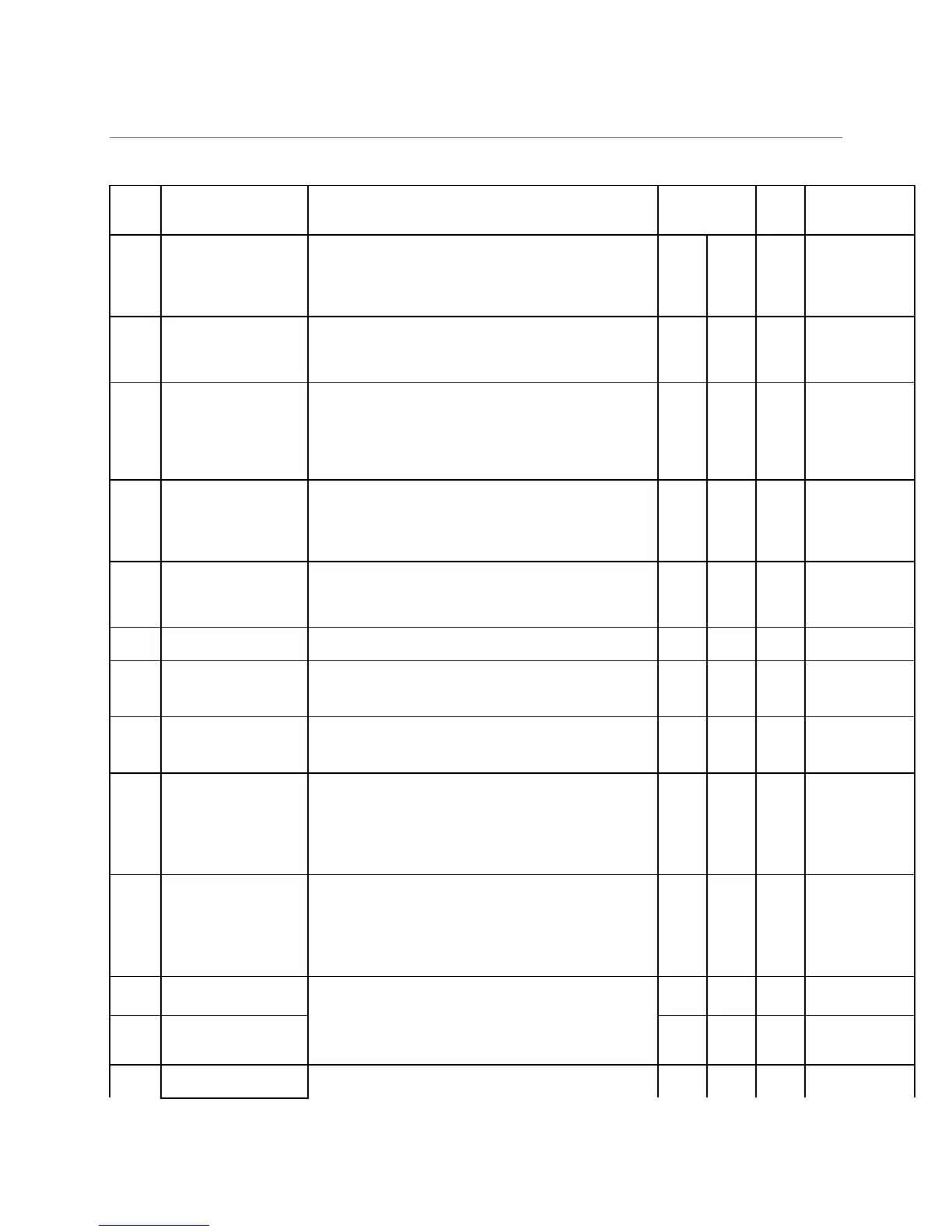

Compressor Phase

Over Current

1. Check the U/V/W connections on drive side

2. Check the compressor motor windings

3. Check the compressor is operating with in

specified limits

Torque Limit Fold

Back Timeout

1. Compressor Torque ≥ foldback protection

value (for 30 seconds).

2. Check if the compressor is operating outside

the specified speed range.

ENVELOPE

FOLDNACK

TIMEOUT

1. Check the line voltage is too low.

2. Check the line voltage for noise.

3. Check the compressor is operating with in

specified limits.

4. If the problem still persists, then it's possibly

a drive component issue. Replace the drive

1. Check the DC bus voltage if it is > 850VDC

2. Check AC Power Supply

3. Check the compressor is operating with in

specified limits.

4. Restart the drive

1. Check the DC bus voltage if it is < 350VDC

2. Check the compressor is operating with in

specified limits.

3. Restart the drive

Check the line voltage if it is > 645VAC

1. Check the line voltage if it is < 500VAC

2. Check the compressor is operating with in

specified limits.

Check if all input cables are connected or any line is

missing. Checking if the voltage is below 500VAC. If

the problem persists, replace the drive

Verify proper airflow over the heat-sink of the drive.

Remove any obstructions. Check that the compressor

is operating within specified limits. Check the

mounting screws on the drive, make sure they are

tight. If the problem, still persists replace the drive.

Verify proper airflow over the heat-sink of the drive.

Remove any obstructions. Check that the compressor

is operating within specified limits. Check the

mounting screws on the drive, make sure they are

tight. If the problem, still persists replace the drive.

1. Check the U/V/W connections on drive side &

compressor side.

2. Check the compressor motor windings

3. Check system charge levels, if too high this

problem can occur.

Compressor Phase

Current Imbalance

INVERTER

CURRENT

IMBALANCE

Loading...

Loading...