2

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

AE5-1377 R2

Application Engineering

BULLETIN

Introduction

Copeland Scroll

®

outdoor condensing units provide the

many benefi ts of scroll compressor technology, coupled

with advanced diagnostic controls, to ensure reliable

performance and operation in foodservice applications.

Electronics are used extensively in its protection and

diagnostic features. These features are controlled by an

electronic integrated control board. The control board

provides base control functions related to temperature

controller, defrost, evaporator fan control, compressor

protection e.g. current overload, phase reversal, liquid/

vapor injection control, self diagnostics and warnings.

These error codes can be seen by an LED display for

easy and rapid troubleshooting and maintenance.

A complete product offering for medium and low

temperature HFC-404A units is being offered in single

and three phase 208/230 volts. The -002 and -012

BOM product is approved for operation in ambients

from 120°F to -10°F. The -022 BOM is featured with

the required components to operate in colder climates.

See Figure 1 for details. For applications outside these

guidelines, please contact Application Engineering.

Nomenclature/Features

See Figure 1 (page 6).

Understanding Actual vs. Standard Airfl ow

To choose the proper coil for your application, the density

of the incoming air needs to be known to calculate the

actual capacity and performance of the system.

A coil’s required capacity can be calculated using the

thermodynamic equation

Q = M x Delta hr

Q = Heat transfer to or from the air (Btuh)

M = Mass fl ow rate of air (lb/hr)

Delta h = Difference between the entering and leaving

air enthalpy or total heat (Btu/lb)

The mass fl ow rate is equal to the density of air times

the face area of the coil times the velocity of the air at

the coil or face velocity.

M = P x A x V

P = Density (lb/ cubic ft.)

A = Face area of coil (square ft.) ~ Fin height x fi n length

V = Air Velocity (ft./min.)

For temperature conversions

( )=

+

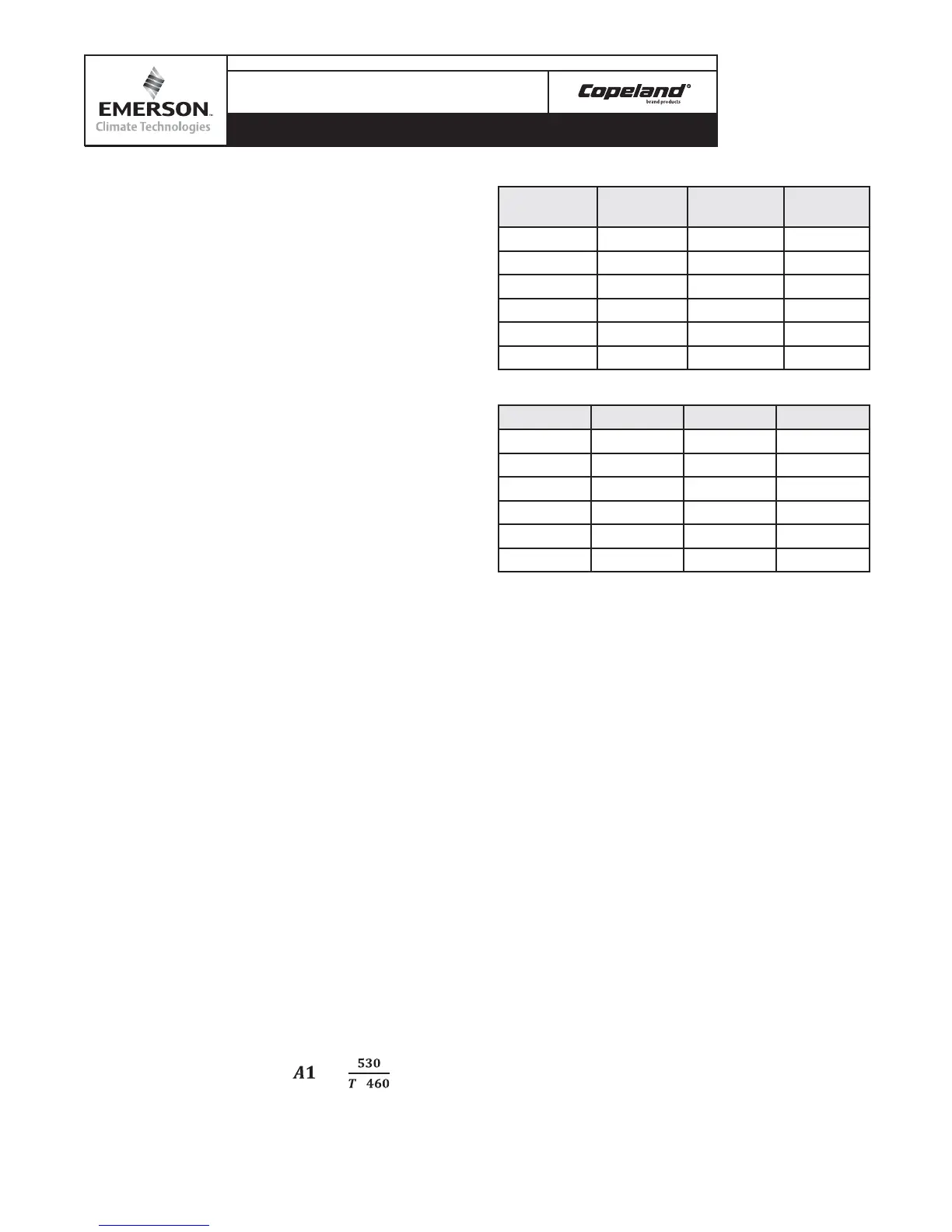

Temperature Conversion Factors

Temp

(degrees F)

Factor A1

Temp

(degrees F)

Factor A1

0 1.15 60 1.02

10 1.13 70 1.00

20 1.10 80 .98

30 1.08 90 .96

40 1.06 100 .95

50 1.04 110 .93

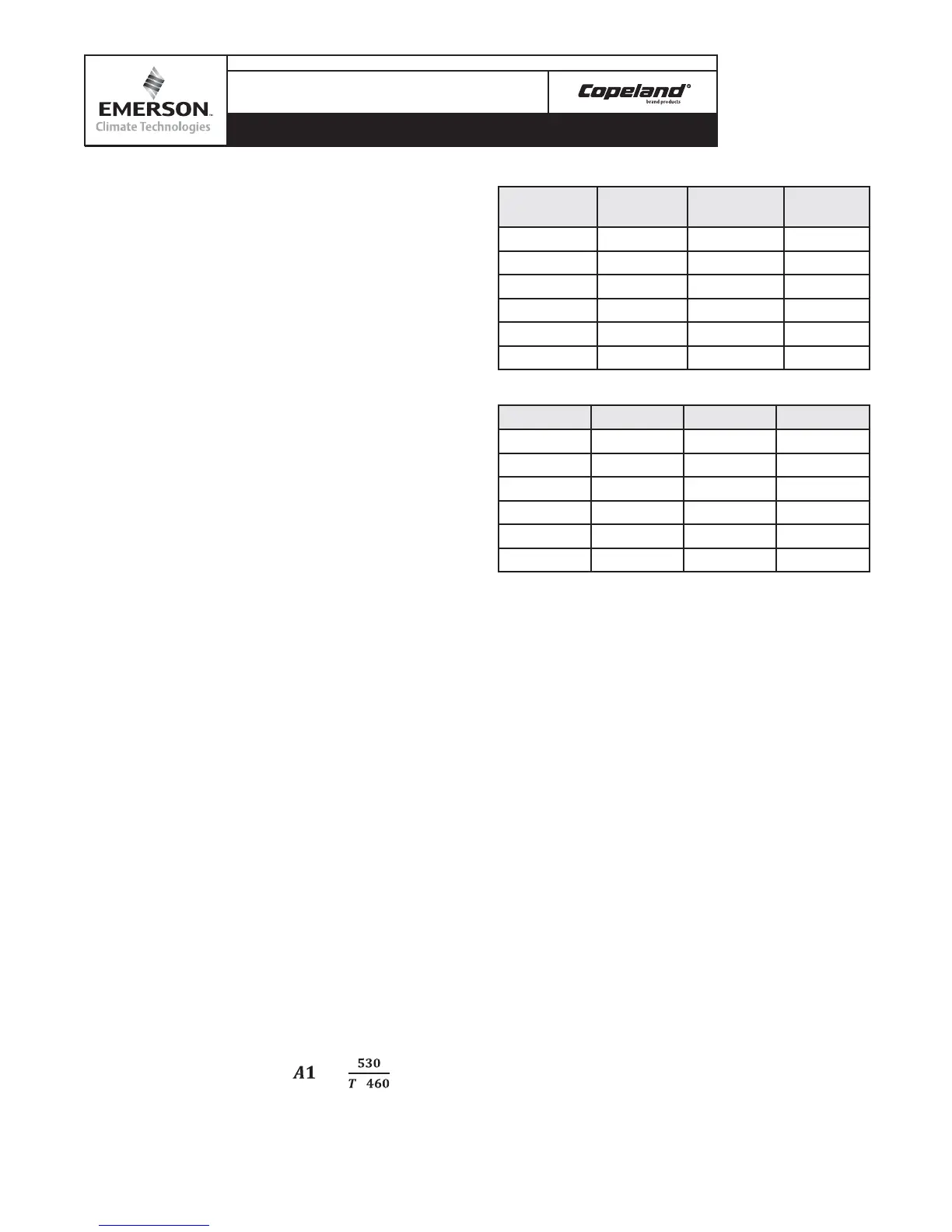

Altitude Conversion Factors (A2)

Alt.- Ft. Factor- A2 Alt.- Ft Factor- A2

0 1.00 3000 .895

500 .982 4000 .864

1000 .965 5000 .832

1500 .947 6000 .802

2000 .930 7000 .771

2500 .912 8000 .743

SCFM= CFM X A1 X A2

Note: all calculations and ratings are based on standard

air at 70°F dry bulb temp and 29.92 Hg atmospheric

pressure (sea level). These tables convert non standard

cfm to standard cfm.

Performance Data

See Tables 1 and 2 (page 10).

Electrical / Physical Data

See

Table 3

(page 11).

Generator Requirements

In situations or locations were an electrical power

generator could be applied in the event of a power

outage, the Copeland Scroll

®

outdoor condensing unit

will operate providing the generator will provide a supply

voltage range of 180-260 VAC along with a frequency

of 47-63 Hz. The electronics control along with the

power board will function properly providing the range

of operating limits is in compliance!

Physical Dimensions

See Figure 2 (page 7).

Installation / Piping Instructions

See Figure 2 for overall dimensions of the units. It is

recommended that a clearance of 8 inches from the

Loading...

Loading...