Instruction Manual

D100399X012

EW Valve

July 2017

14

Trim Maintenance

WARNING

Avoid personal injury or property damage from sudden release of process pressure. Before performing any maintenance

operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the pneumatic actuator loading pressure and relieve any actuator spring precompression.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

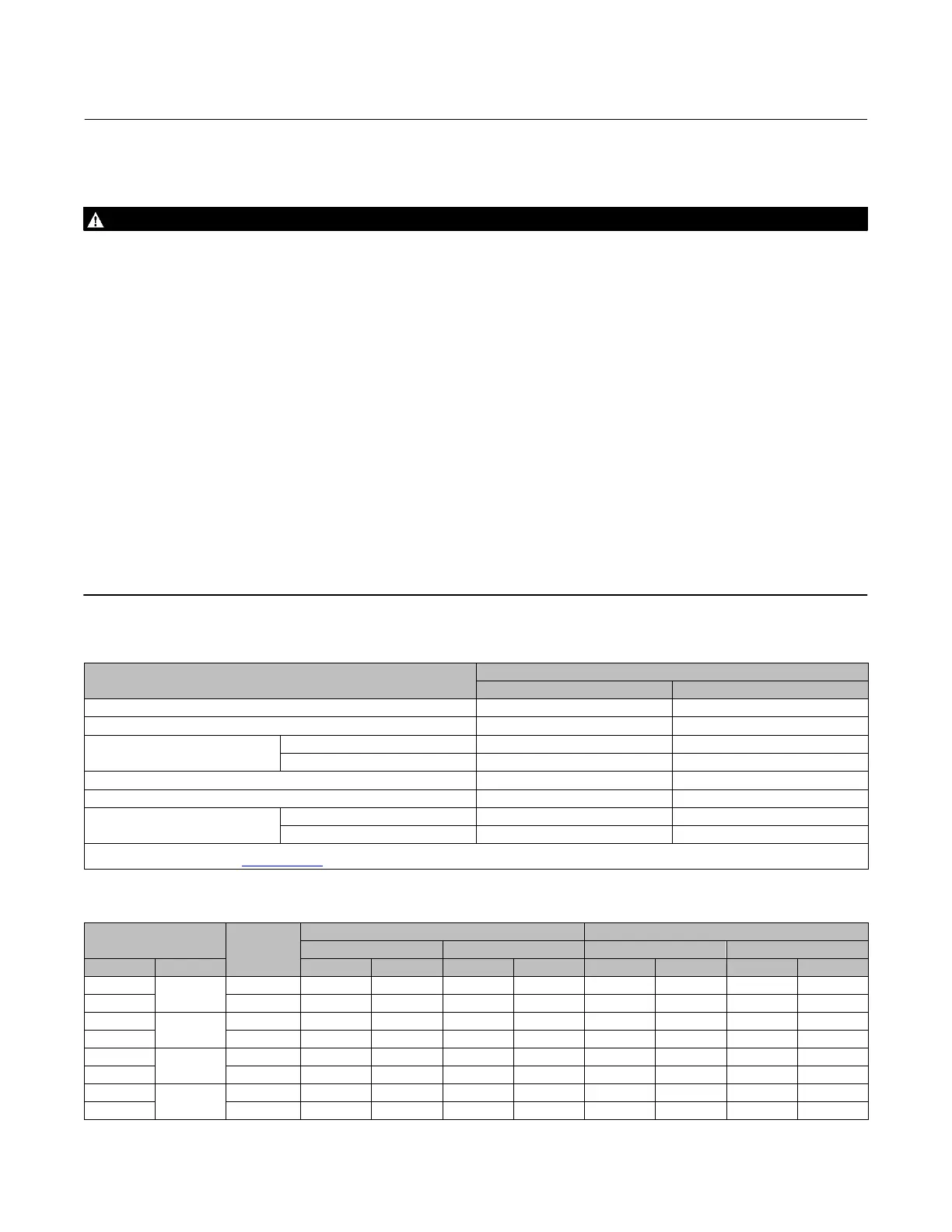

Table 5. Body‐to‐Bonnet Bolt Torque Guidelines

VALVE SIZE, NPS

BOLT TORQUES

(1,

2)

NSm LbfSft

4x2 102 75

6x4 or 8x4 259 191

8x6

CL300 or CL600 548 404

CL900 1315 970

10x8 745 550

12x6 548 404

12x8

CL300 or CL600 732 540

CL900 2712 2000

1. Determined from laboratory tests.

2. For other materials, contact your Emerson sales office

or Local Business Partner for torques.

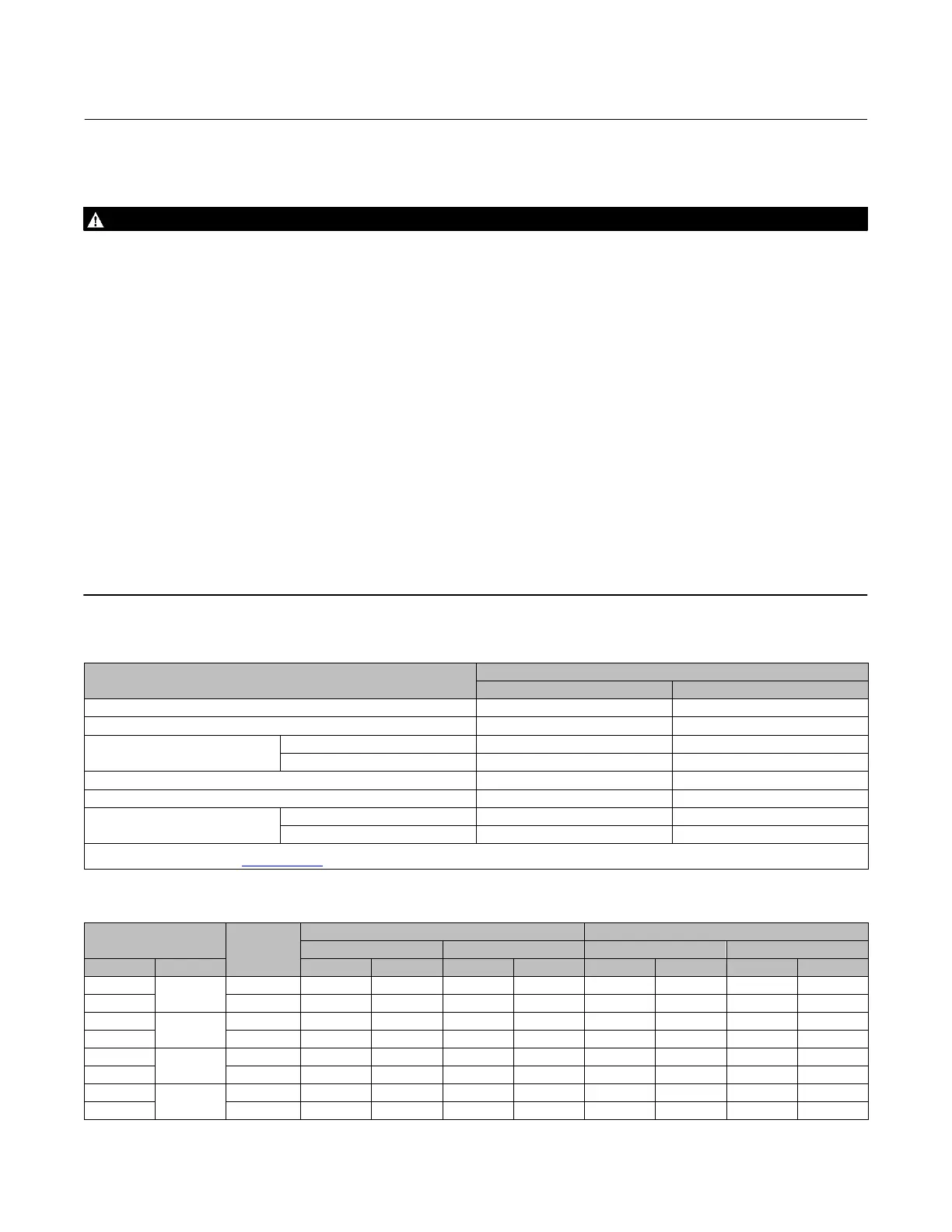

Table 6. Recommended Torque for Packing Flange Nuts

VALVE STEM

DIAMETER

PRESSURE

RATING

GRAPHITE TYPE PACKING PTFE TYPE PACKING

Minimum Torque Maximum Torque Minimum Torque Maximum Torque

mm Inches NSm LbfSIn NSm LbfSIn NSm LbfSIn NSm LbfSIn

12.7

1/2

CL300 7 59 10 88 3 28 5 42

12.7 CL600 9 81 14 122 4 39 7 58

19.1

3/4

CL300 15 133 23 199 7 64 11 95

19.1 CL600 21 182 31 274 10 87 15 131

25.4

1

CL300 26 226 38 339 12 108 18 162

25.4 CL600 35 310 53 466 17 149 25 223

31.8

1‐1/4

CL300 36 318 54 477 17 152 26 228

31.8 CL600 49 437 74 655 24 209 36 314

Loading...

Loading...