Operating Instructions Liquiphant M FTL50 / FTL51

28 Endress+Hauser

7Troubleshooting

Troubleshooting

Supplement

If the switching behavior of the fork is abnormal, the fork frequency can be measured at PIN 4 of

the diagnosis socket. With electronic inserts FEL 51/52/54/55/56/57/58, this is a sinusoidal

vibration whose amplitude makes it possible to determine the condition of the fork.

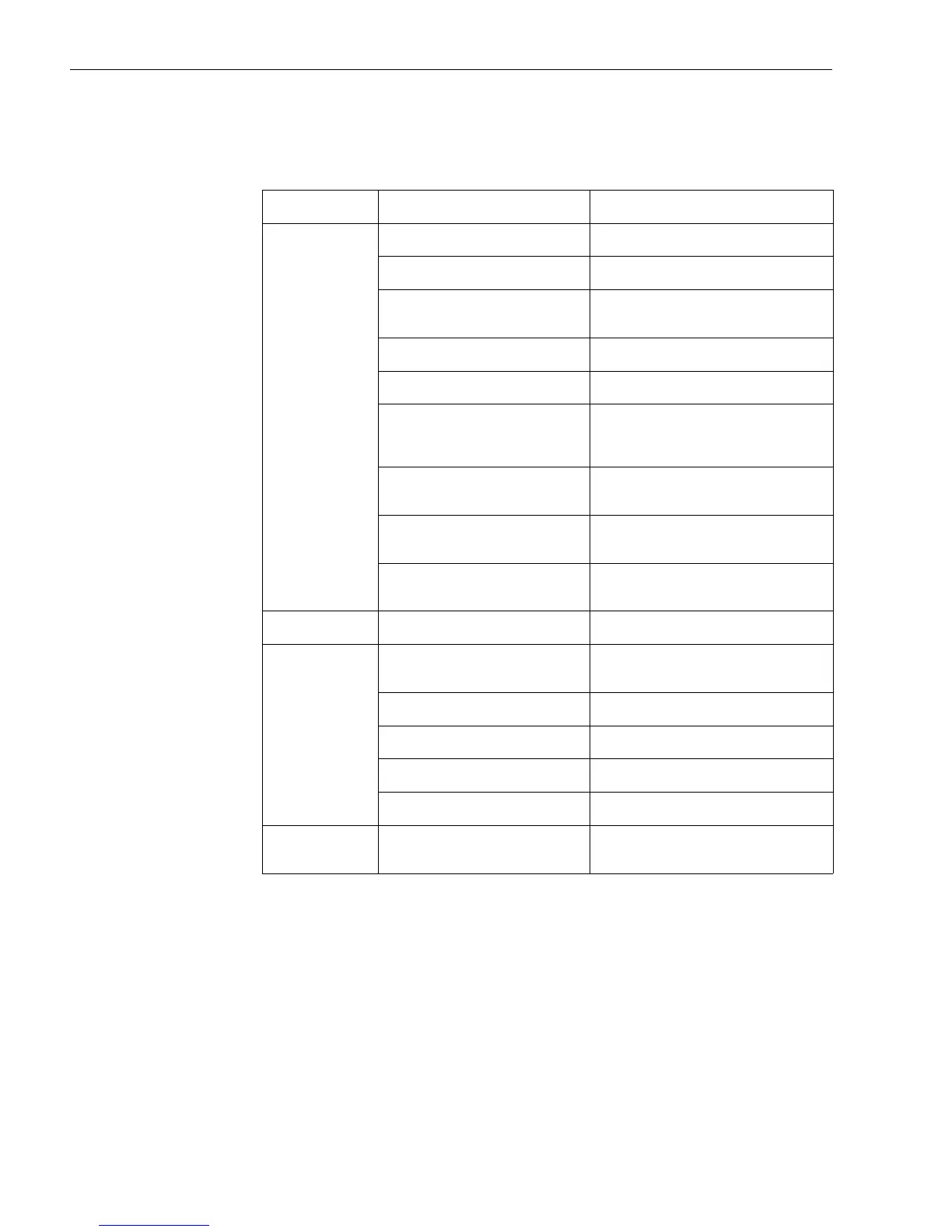

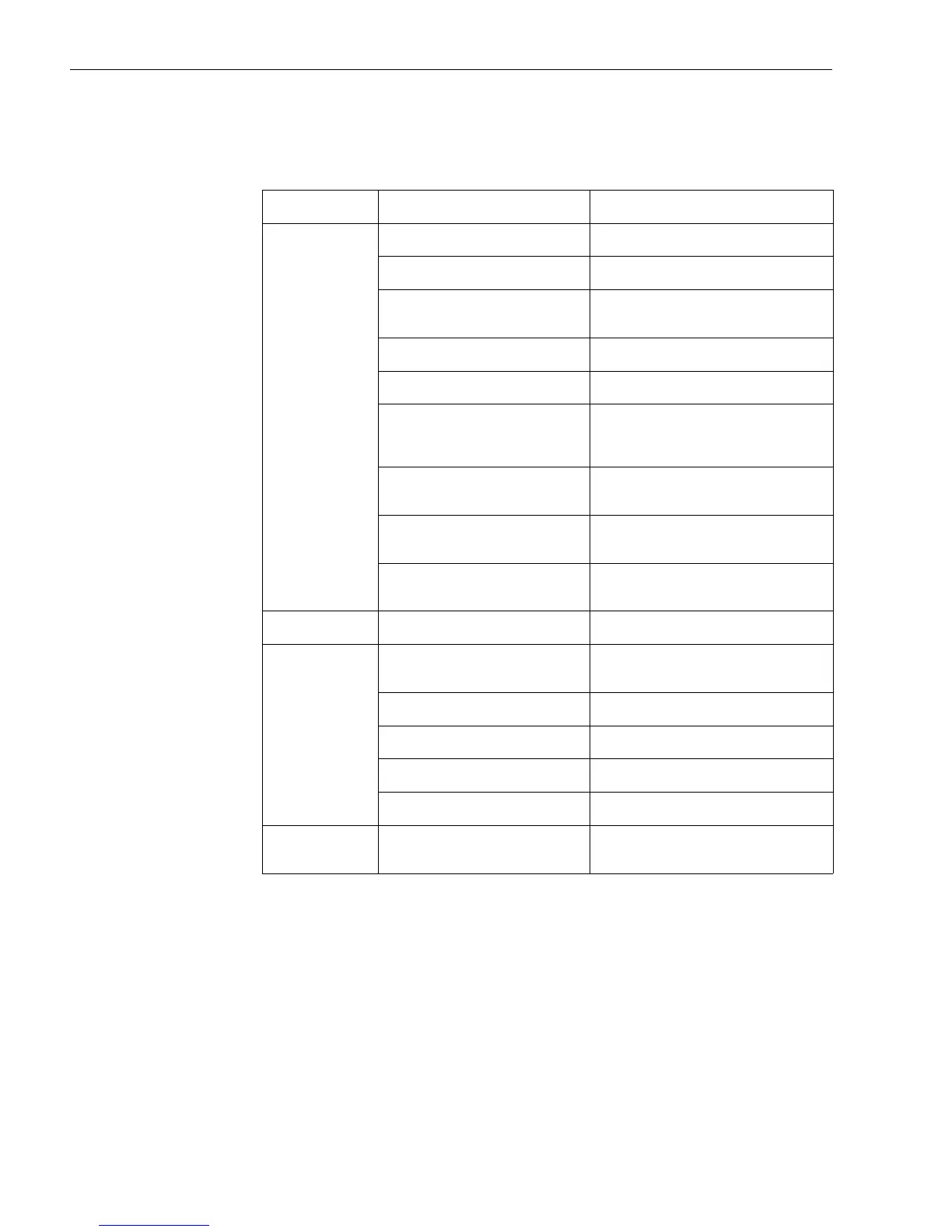

Fault Reason Remedy

Does not switch No power Check power

Faulty signal line Check signal line

Faulty electronic insert

– FEL51 connected directly to L1 and N

Exchange

– always connect FEL51 via external load

Density of liquid too low Set density to >0.5 at electronic insert

Fork encrusted Clean fork

Fork corroded

(Indication on FEL: red/yellow flashes,

FEL58: green flashes (0.3 Hz)

Exchange fork and process connection

FEL51: Internal resistance of connected

relay too large

Connect suitable relay

FEL51: Holding current of connected

relay too low

Connected resistor in parallel with relay

FEL54: Contacts welded together (after

short-circuit)

Exchange FEL54; put fuse in contact circuit

Switches incorrectly Min-/Max- fail-safe mode set wrong Set correct mode at electronic insert

Sporadic faulty

switching

Thick heavy foam, very turbulent

conditions, foaming liquid

Mount Liquiphant in bypass

Extreme RFI Use shielded cable

Extreme vibration Decouple, damp, turn fork 90°

Water in housing Screw cover and cable gland tight

FEL52: Output overloaded Reduce load, (cable) capacitance

Switches incorrectly

after power failure

FEL57: behavior during switch-on test

(functional test)

Observe switching behavior of FEL57; after

power failure block plant control for up to 45 s

Loading...

Loading...