4

Use whenever sudden pressure drops are

anticipated (such as when testing vessels to

destruction).

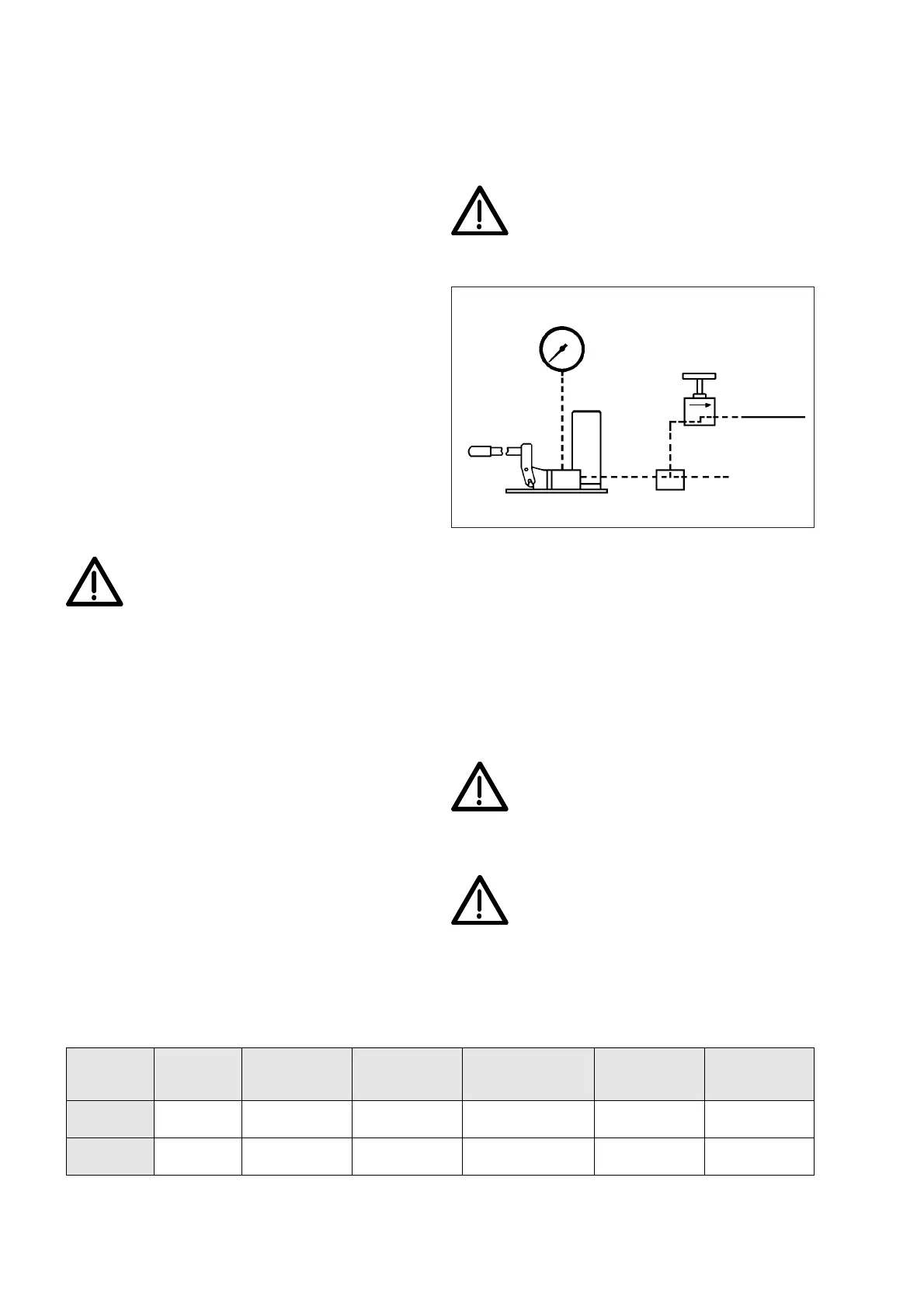

Install gauge as shown in illustration 3. The shut-off

valve (Modelnr. 72-750) protects the gauge against

recoil damage when the test vessel ruptures. For

maximum protection, the shut-off valve should be

nearly closed during operation of the pump.

6.0 OPERATION

6.1 To Pressurize the System

Turn pump release valve to maximum clockwise

"closed" position (finger-tight). Operate the pump

handle until the desired system pressure is attained

or operation is completed.

NOTE: "Spongy" pump action indicates that there is

air in the pump or external hydraulic system.

6.2 To Relieve Pressure from the System

Turn pump release valve counterclockwise to "open"

position (approximately one turn).

WARNING: Check pressure gauge to be

sure system hydraulic pressure has

dropped to zero before attempting to

disconnect pump.

6.3 To Purge Air From the Pump

1. Open pump release valve (approx. one turn).

2. Loosen outlet port gland nut.

3. Close pump release valve.

4. Operate pump handle until air is expelled.

5. Torque outlet port gland nut to 67 Nm [50 Ft.lbs].

6. Check pump operation. Repeat above procedure

if necessary.

7. If pump action continues to feel "spongy", bleed

the external hydraulic system.

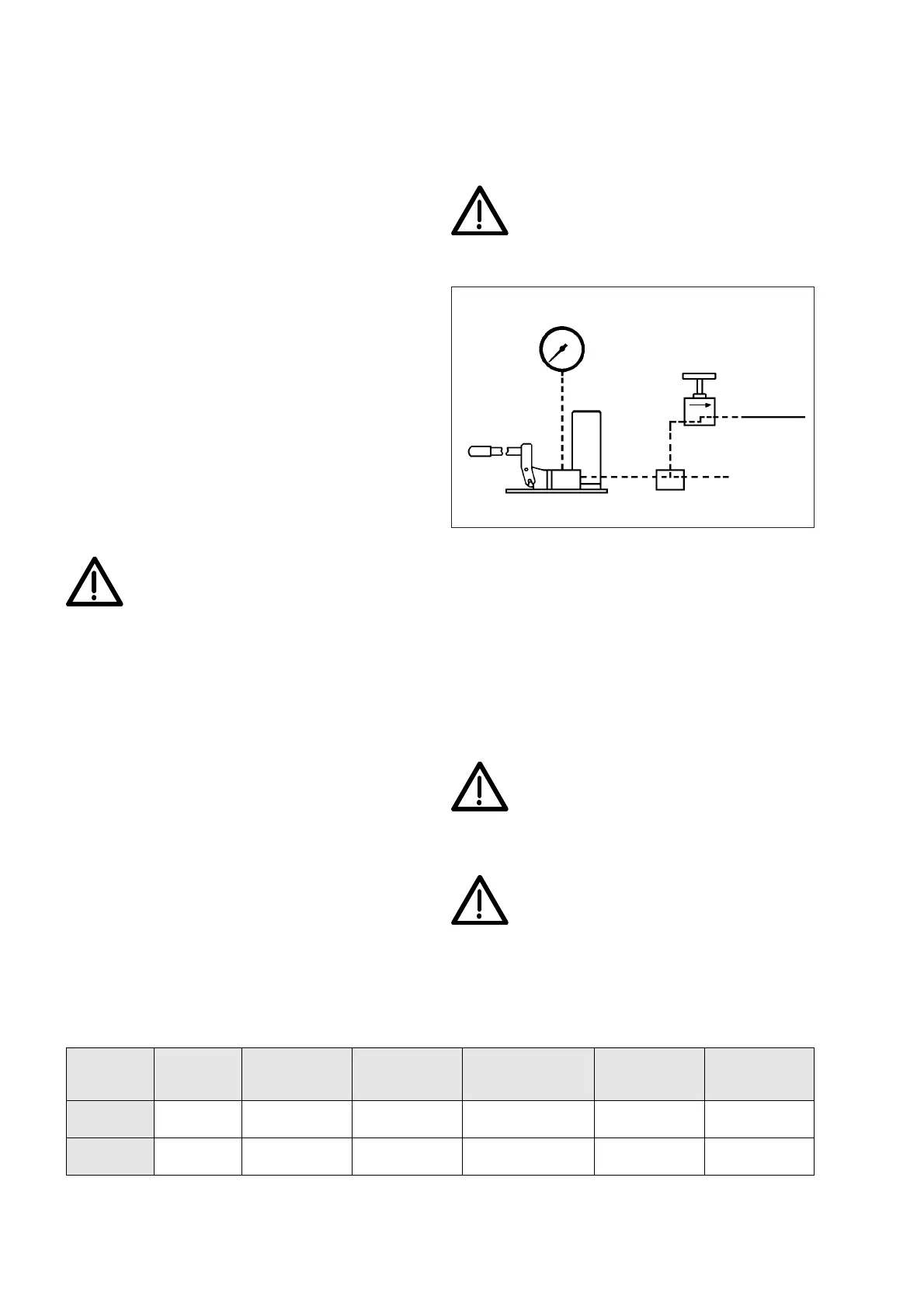

7.0 PRESSURE TESTING OF LARGE VESSELS

1. Install a tee (Modelnr. 43-300) and shut-off valve

(Modelnr. 72-750) as shown in Figure 4.

CAUTION: Install the shut-off valve so that

the flow arrow points away from the tee and

toward the fluid supply line so that the valve

inlet port will be subjected to the high test pressures.

See Figure 4.

2. Remove pump reservoir filler plug and fill pump

reservoir with test fluid.

3. To fill test vessel:

a. Turn the pump release valve to maximum

clockwise "closed" position (finger-tight).

b. Open fluid supply shut-off valve.

c. When test vessel is filled, close fluid supply

shut-off valve.

4. Operate pump until desired system pressure is

developed.

CAUTION: The fluid supply shut-off valve

must remain closed at all times during the

pressure test.

5. After test is completed, open pump release valve.

WARNING: Check pressure gauge to be

sure system hydraulic pressure has

dropped to zero before attempting to drain

test vessel or disconnect pump.

illustration 4 – Large vessel pressure test

Gauge

TeePump

Shut-Off

Valve

Fluid supply

line

Model

Number

11-100

11-400

Pressure

Rating

Type of

pump

10000 psi

700 bar

40000 psi

2800 bar

Single-

speed

Single-

speed

Usable Oil

Capacity

45 in

3

737 cm

3

45 in

3

737 cm

3

Oil Displacement

per Stroke

.152 in

3

2,49 cm

3

.038 in

3

0,62 cm

3

Piston

Diametre

.50 inch

12,7 mm

.25 inch

6,4 mm

Piston

Stroke

.780 inch

19,8 mm

.780 inch

19,8 mm

TABLE 1 – SPECIFICATIONS

Loading...

Loading...