Design V260

2

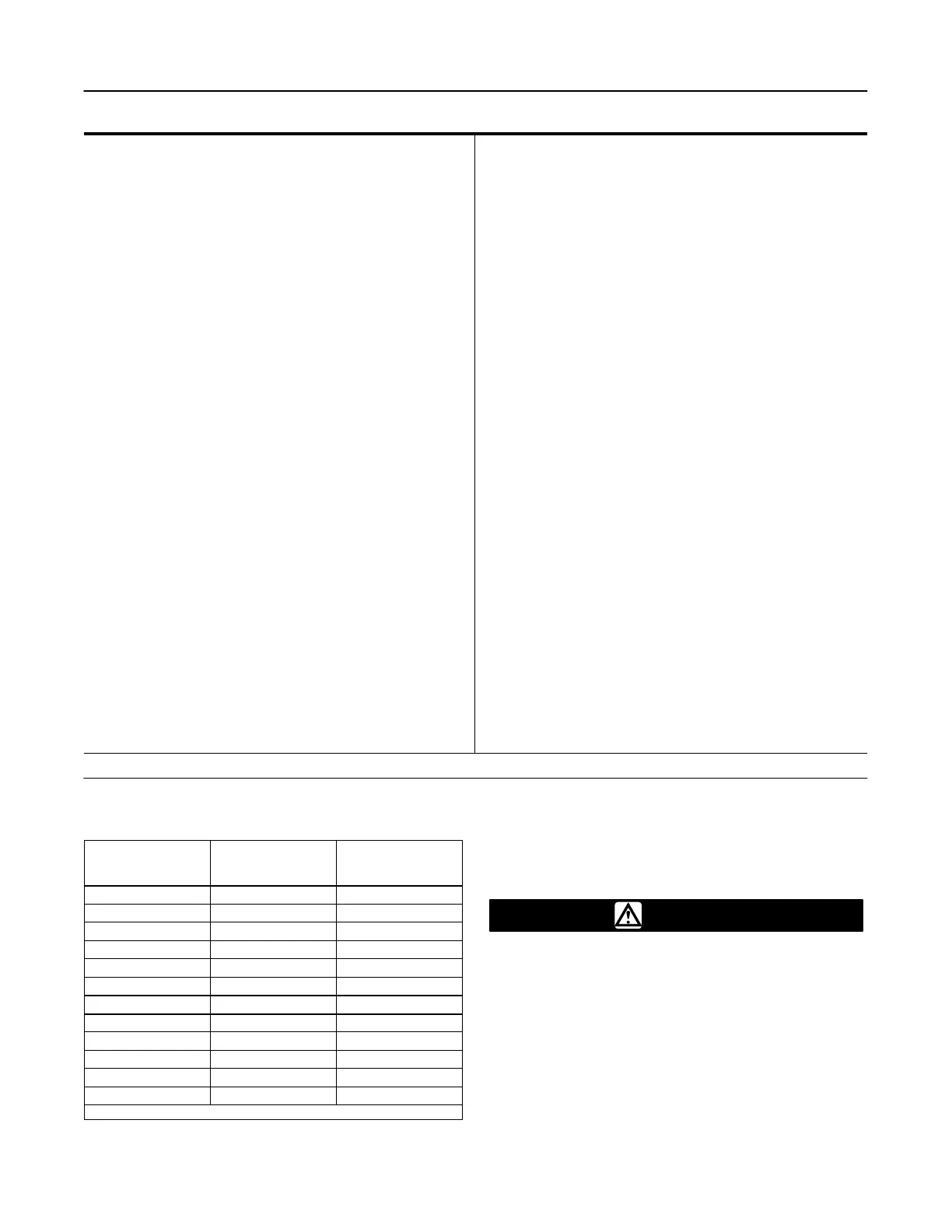

Table 1. Specifications

Valve Body Size and End Connection Styles

(1)

8-, 10-, 12-, 16- and 20-inch flanged valves with

ANSI Class 150, 300 and 600 raised-face or ring-

type joint flanges compatible with ASME B16.5.

See table 2 for face-to-face dimensions

Maximum Inlet Pressures and Temperatures

(1)

Consistent with Class 300 or 600 pressure-tempera-

ture ratings per ASME B16.34

Maximum Allowable Shutoff Pressure Drop

(1)

For Single-Seal and Dual-Seal Construction:

(Except where further limited by the pressure-tem-

perature rating of valve body material)

For LF2 valve body material:

Class 300: 51 bar (740 psi) at 38_C (100_F)

Class 600: 103 bar (1480 psi) at 38_C (100_F)

Seal Material and Temperature Capability

(1)

J Delrin (Standard) –46 to 82_C (–50 to 180_F)

J PTFE/PEEK

(2)

(Optional) –46 to 232_C (–50 to

450_F)

J S31600 (316 SST)/Alloy 6 (Optional) Consult

factory

Flow Characteristic

Modified equal percentage

Flow and Shutoff Direction

Unidirectional flow for Design V260 is forward flow.

Seal is upstream.

J Single Seal Constructions: Should be used for

unidirectional flow and unidirectional shutoff only.

J Dual Seal Constructions: V260A and V260C

may be used for unidirectional or bidirectional flow.

V260B should be used for unidirectional flow only

for most effective anti-cavitation protection. Bidirec-

tional shutoff requires the dual seal construction.

Shutoff Classification

Single-Seal Composition Constructions: 0.001%

of maximum valve capacity (less than 10% of ANSI/

FCI 70-2 Class IV)

Dual-Seal Composition Constructions: 0.001% of

maximum valve capacity (less than 10% of ANSI/

FCI 70-2 Class IV)

Single-Seal Metal Constructions: Class IV per

ASME B16.34 FCI 70-2

Dual-Seal Metal Constructions: Class IV per

ASME B16.34 FCI 70-2

Maximum Ball Rotation

90 degrees

Actuator Mounting

Right-hand or left-hand mounted as viewed from the

valve inlet for forward flow

Approximate Weight

See table 2

1. The pressure-temperature limits in this instruction manual and any applicable standard or code limitation for valve should not be exceeded.

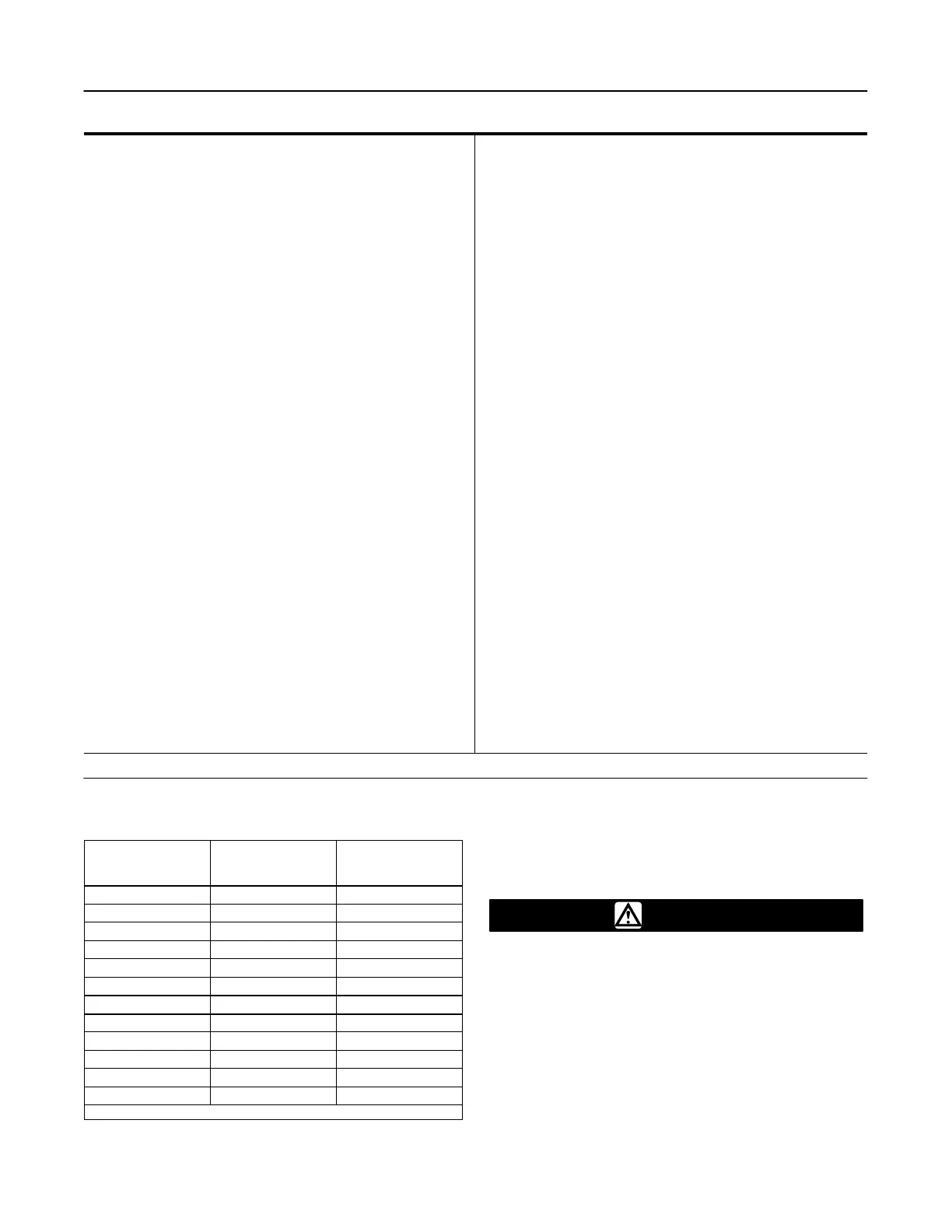

Table 2. Face-to-Face Dimensions and Approximate Weights

VALVE SIZE,

FACE-TO-FACE APPROXIMATE

INCHES

(CLASS 600

(1)

)

DIMENSIONS

WEIGHT

mm kg

8 661 424

10 788 653

12 840 882

16 990.6 2472

20 1144 4313

Inches Pounds

8 26.04 975

10 31.04 1550

12 33.07 2025

16 39.0 5450

20 47.0 9500

1. For Class 300 valves, face-to-face dimensions are the same as Class 600 valves.

Installation

WARNING

D Personal injury or equipment dam-

age can result from the sudden release

of process pressure if service conditions

can exceed valve or mating pipe flange

pressure ratings. To avoid such injury

or damage, provide a relief valve for

over-pressure protection as required by

government or accepted industry codes

and good engineering practices.

Loading...

Loading...