- 9 -

4. Check that harness has enough slack to allow

outboard to operate throughout its full steering

and tilt ranges.

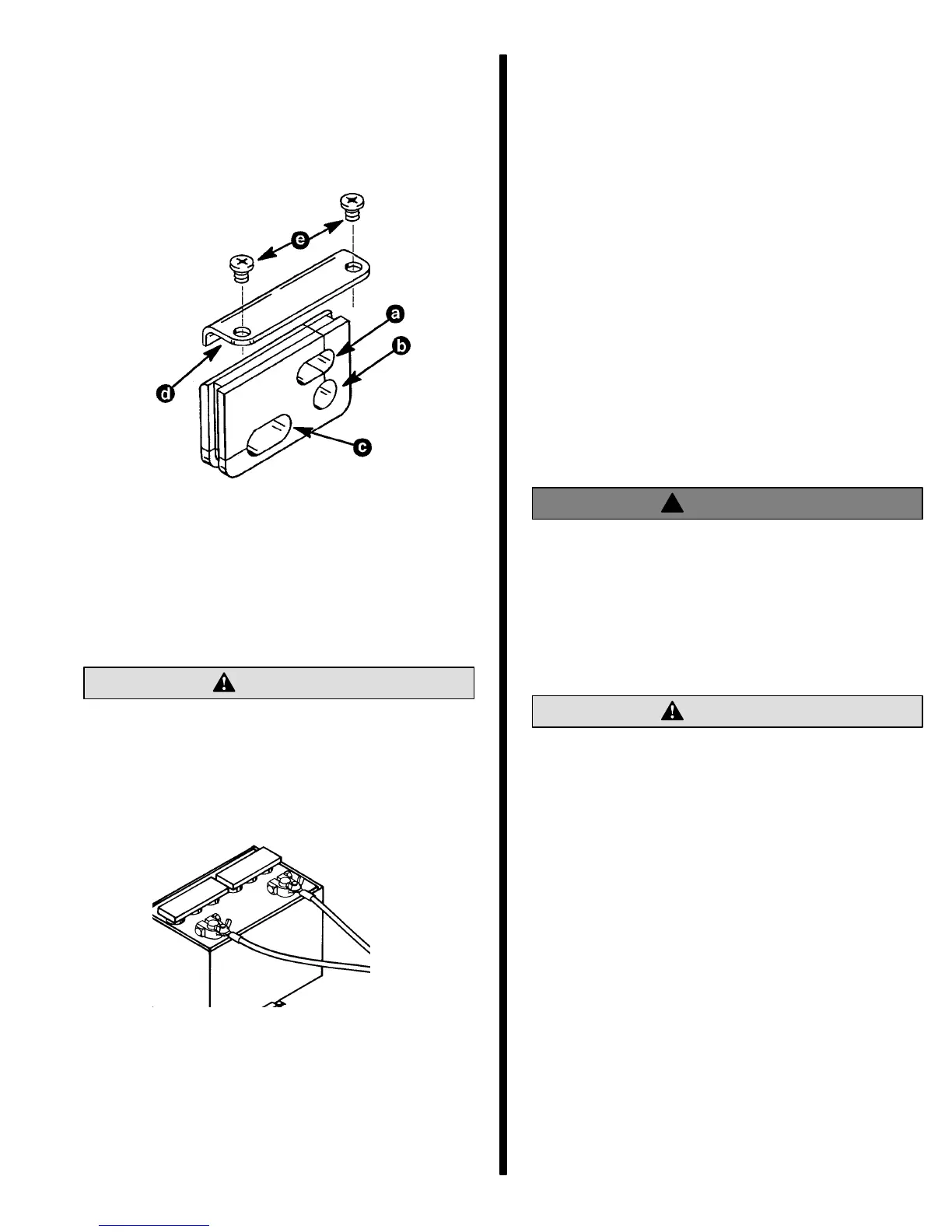

5. Place shift cable, battery cable, and remote con-

trol wire harness in openings in grommet. Secure

grommet in bottom cowl with retainer and screws.

Port

Bottom Cowl Grommet

a - Opening for Battery Cable

b - Opening for Control Harness

c - Opening for shift cable

d - Retainer

e - Screws

Battery Connections

CAUTION

Failure to observe correct polarity when connect-

ing battery cables to battery will result in damage

to the charging system.

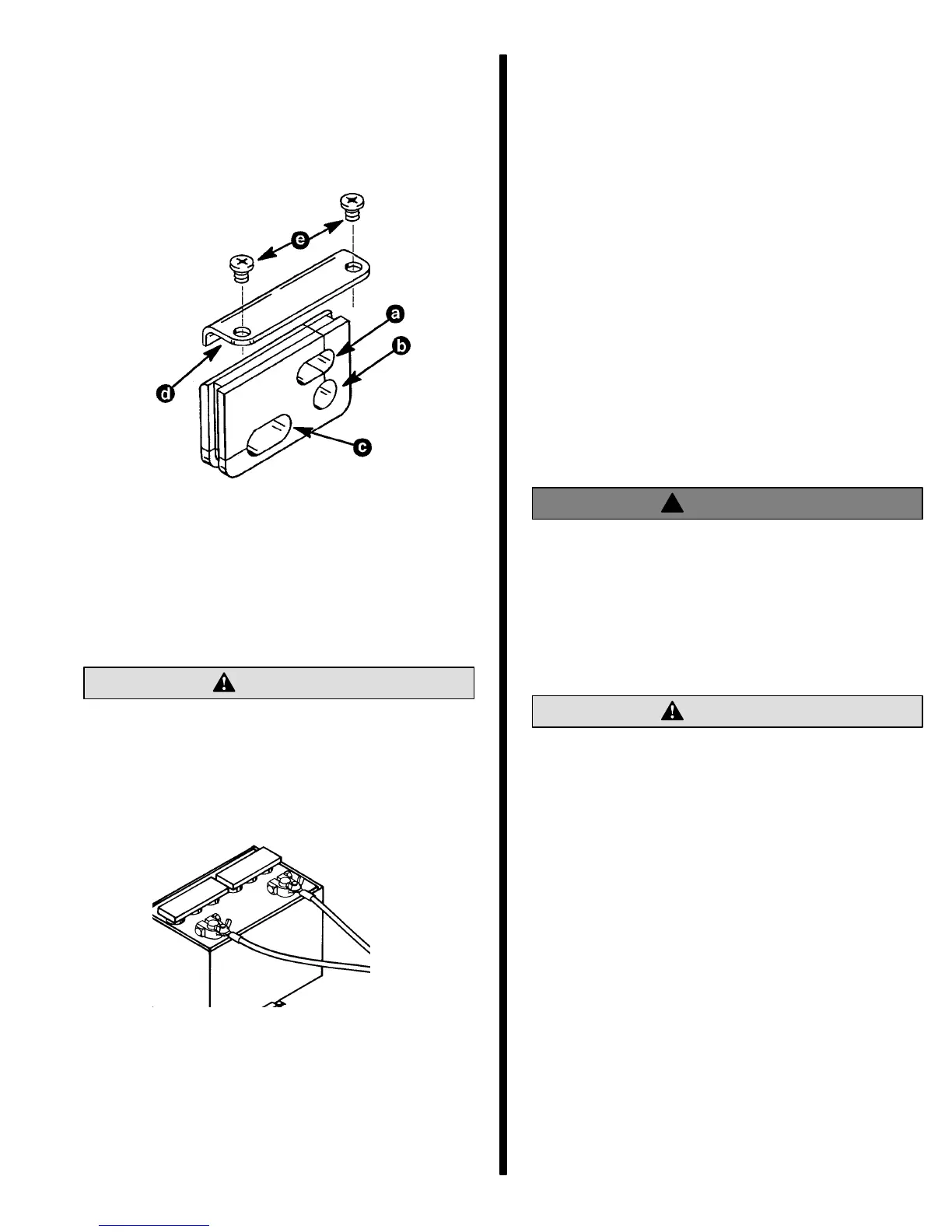

Connect battery cables from engine to battery. Con-

nect red battery cable to positive battery terminal and

black battery cable to negative battery terminal.

(+)

(–)

Propeller Selection

Refer to “Quicksilver Accessory Guide” for a com-

plete list of available propellers.

For best all around performance from your outboard/

boat combination, select a propeller that allows the

engine to operate in the upper half of the recom-

mended full throttle RPM range with the boat normally

loaded (refer to Specifications in the Operators Man-

ual). This RPM range allows for better acceleration

while maintaining maximum boat speed.

If changing conditions cause the RPM to drop below

the recommended range (such as warmer, more

humid weather, operation at higher elevations, in-

creased boat load or a dirty boat bottom/gear case)

this may require a propeller change or cleaning to

maintain performance and ensure the outboard’s

durability.

Check full-throttle RPM using an accurate tachome-

ter with the engine trimmed out to a balanced steering

condition (steering effort equal in both directions)

without causing the propeller to “break loose.”

Propeller Installation

!

WARNING

When the propeller shaft is rotated and the en-

gine is in gear, there is the possibility for the en-

gine to crank over and start. To prevent this type

of accidental engine starting and possible seri-

ous injury caused from being struck by a rotating

propeller, always set the remote control into neu-

tral and remove spark plug leads when you are

servicing the propeller.

CAUTION

If the propeller moves forward-and-aft on the pro-

peller shaft (is loose), retighten the propeller nut.

Operation with a loose propeller could cause

damage to the thrust hub and gear housing dur-

ing acceleration, deceleration or when shifting

gears.

IMPORTANT: To assure that the propeller remains

secure on the shaft during the season, periodical-

ly check propeller locknut for tightness.

To prevent the propeller hub from corroding and seiz-

ing to the propeller shaft, especially in salt water, al-

ways apply a coat of Quicksilver Anti-Corrosion

Grease to the entire shaft at recommended mainte-

nance intervals and each time the propeller is re-

moved.

1. Shift remote control into neutral position.

2. Remove leads from spark plugs to prevent engine

from starting.

Loading...

Loading...