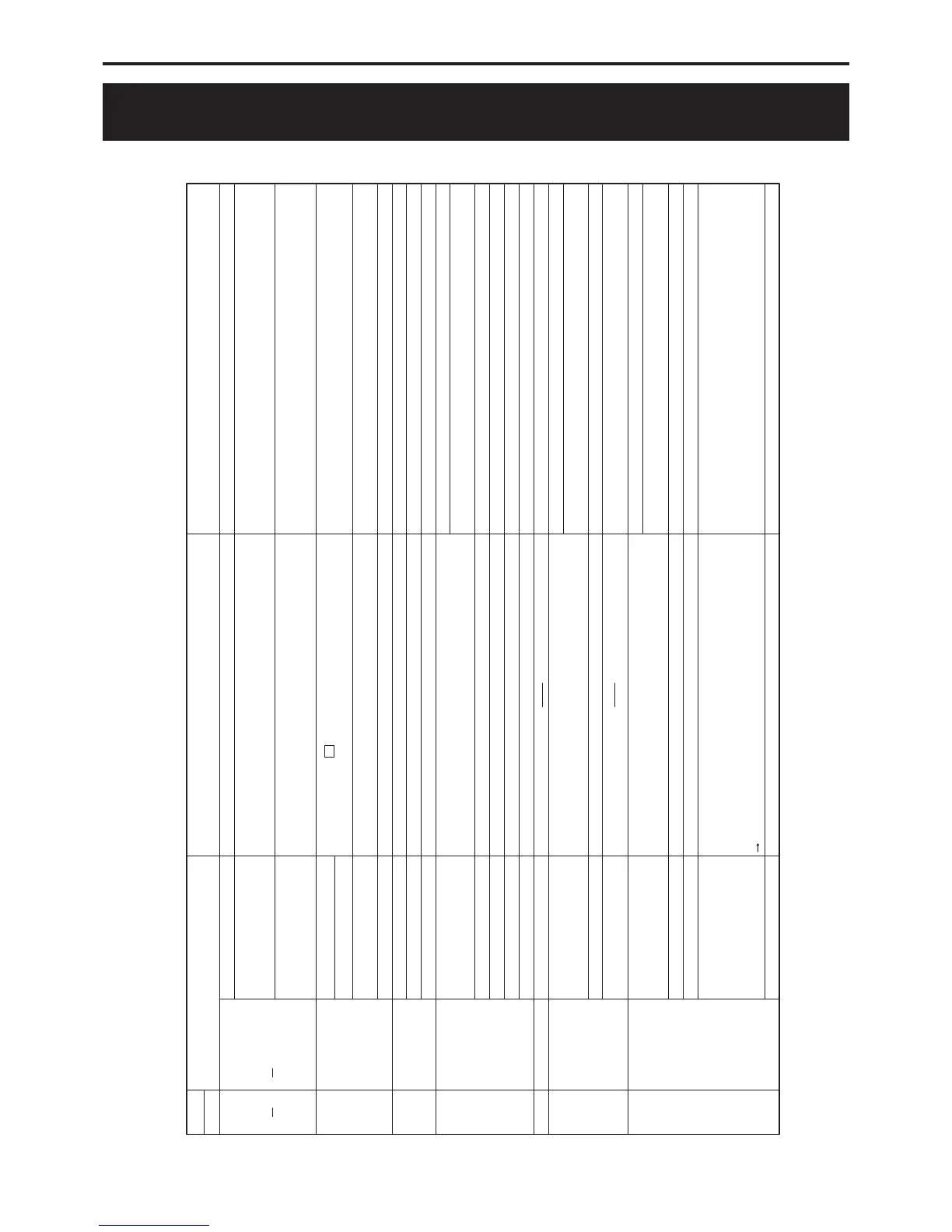

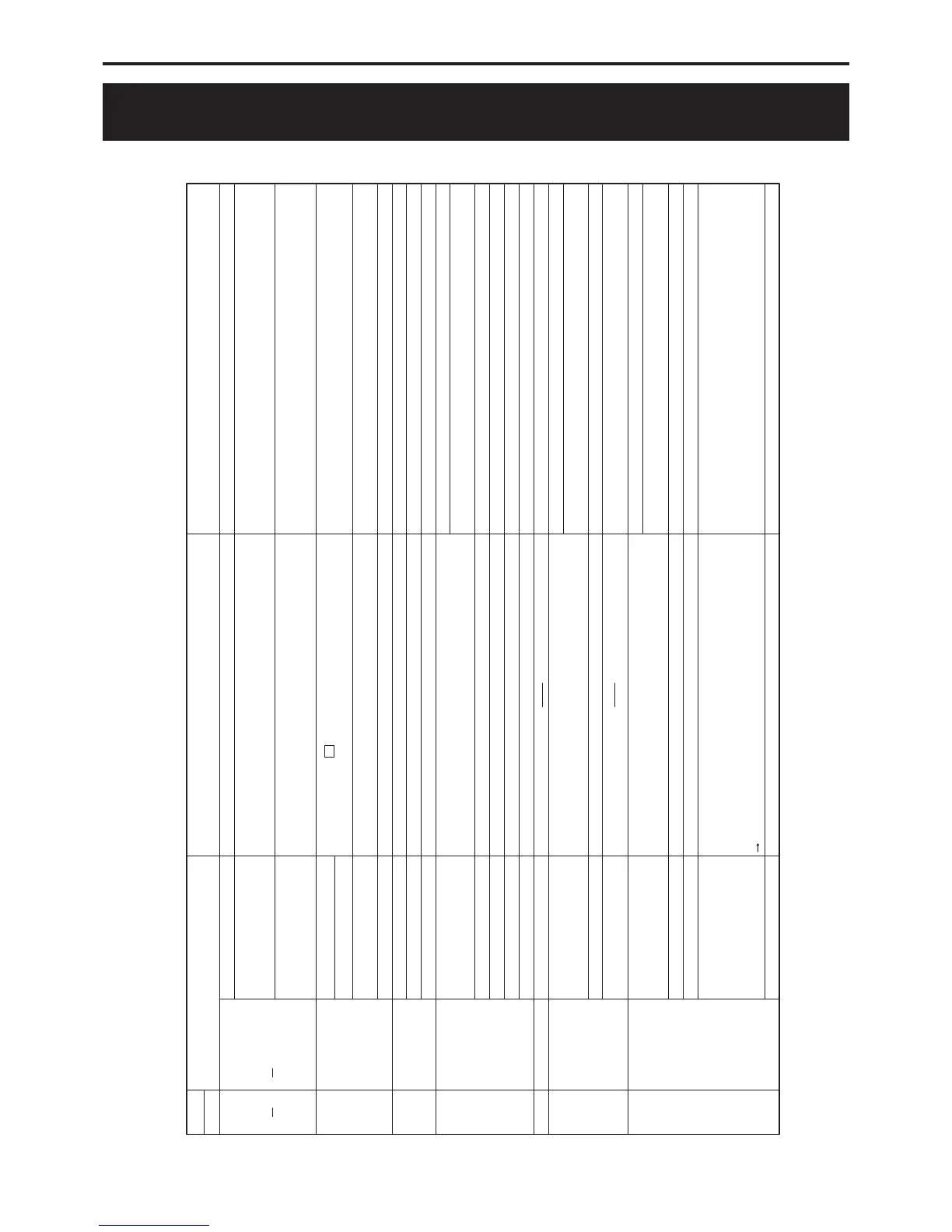

APPEARANCE, PORTION, PARTS SEEMED WRONG

check the power supply

check the electric continuity by tester [see g. 1]

METHOD OF CHECK TROUBLESHOOTING

POWER SUPPLY

FUSE CF3 (250V T5A)

check the electric continuity by tester [see g. 1]FUSE CF1 (250V T25A)

Discharge

temperature Error

check the service valve and refrigerant circuit (pipe)

check the resistance by tester [see table 1]

check the resistance by tester [see table 2]

CT disconnection

protective action

against excess

current AC current

detection

check the power voltage (230V)

GAS LEAKAGE

check the place of installation (blockage of air inlet & outlet )

check the excess gas

UNREASONABLE OPERATION

UNDER OVERLOAD

PCB (CONTROLLER)

DROP OF POWER VOLTAGE

MOMENTARY STOP OF POWER

(IN CASE OF LIGHTNING)

A1

A3

A4

DC voltage Error

FUSE CF4 (250V T3.15A)

FAN MOTOR

A0

POWER MODULE

take o the terminals (orange and blue) and check the resistance between

orange-blue if the resistance is over 100kΩ, POWER MODULE is normal

POWER SUPPLY check the power supply

(*1) When checking fan motor and/or pump, turn o the power supply completely and touch their terminal or connector

take o the connector 9 , and check the resistance between red-black

in the connector if the resistance is over 100kΩ, FAN MOTER is normal

SENSOR, TEMP. SUCTION

SENSOR, TEMP. DISCHARGE

abnormal revolution

of compressor

A5

POWER MODULE

protective action

against excess

current DC current

detection

check the place of installation (blockage of air inlet & outlet )

check the excess gas

check the power voltage (230V)

UNREASONABLE OPERATION

UNDER OVERLOAD

DROP OF POWER VOLTAGE

FUSE CF2 (250V T15A)

other than described above

check the electric continuity FUSE CF2 (250V T15A) by tester

A2

POWER MODULE

COMPRESSOR

operate without the junction connector of compressor lead wire

check the place of installation (blockage of air inlet & outlet )

check the excess gas

check the power voltage (230V)

UNREASONABLE OPERATION

UNDER OVERLOAD

DROP OF POWER VOLTAGE

FUSE CF2 (250V T15A)

check the electric continuity FUSE CF2 (250V T15A) by tester

COMPRESSOR other than described above

check the resistance of POWER MODULE by tester

take off the junction connector of compressor lead wire

measure resistance between the connector pins of junction connector, six

times between white-black, black-red, red-white respectively by changing

the polarity

if all the figures show over 100kΩ, POWER MODULE is normal

conrm the power supply.

if CF3 is blown, it should be replaced and check if there is a short-circuit at a connector

of the 4-way valve coil, the heater for tank, or the circulation pump. [see g 4,5,6]

if a short-circuit is found, the parts should be replaced.

if CF1 is blown, PCB(CONTROLLER) should be replaced and check the resistances

between pink-gray and orange-blue in the connector of POWER MODULE. [see g 7]

if these values are below 100kΩ , POWER MODULE should be replaced.

collect refrigerant once, then recharge with prescribed mass.

SENSOR, TEMP. SUCTION should be replaced.

SENSOR, TEMP. DEFROST should be replaced.

PCB(CONTROLLER) should be replaced.

ensure the installation position to avoid blockage of air inlet & outlet.

conrm the power supply voltage. (230V)

restart operation.

if excess gas is observed, collect all refrigerant once, then recharge with

prescribed mass.

if these values are below 100kΩ, POWER MODULE should be replaced.

if FAN MOTOR is abnormal, it should be replaced. and check the electric continuty

fuse CF4 by tester . [see g 2]

if CF4 is blown

, it should be replaced.

conrm the power supply.

ensure the installation position to avoid blockage of air inlet & outlet.

if excess gas is observed, collect all refrigerant once, then recharge with

prescribed mass.

COMPRESSOR should be replaced.

if CF2 is blown, PCB(CONTROLLER) should be replaced.

COMPRESSOR should be replaced.

if the same error code appears again, POWER MODULE should be replaced.

conrm the power supply voltage. (230V)

ensure the installation position to avoid blockage of air inlet & outlet.

if excess gas is observed, collect all refrigerant once, then recharge with

prescribed mass.

conrm the power supply voltage (230V)

if any of these values is below 100kΩ, POWER MODULE should be replaced.

if CF2 is blown, POWER MODULE and PCB(CONTROLLER) should be replaced.

ERROR

CODES

UNIT

Loading...

Loading...