What to do if Fujitsu WPYA100LA has a gas leakage?

- KKenneth OlsonAug 2, 2025

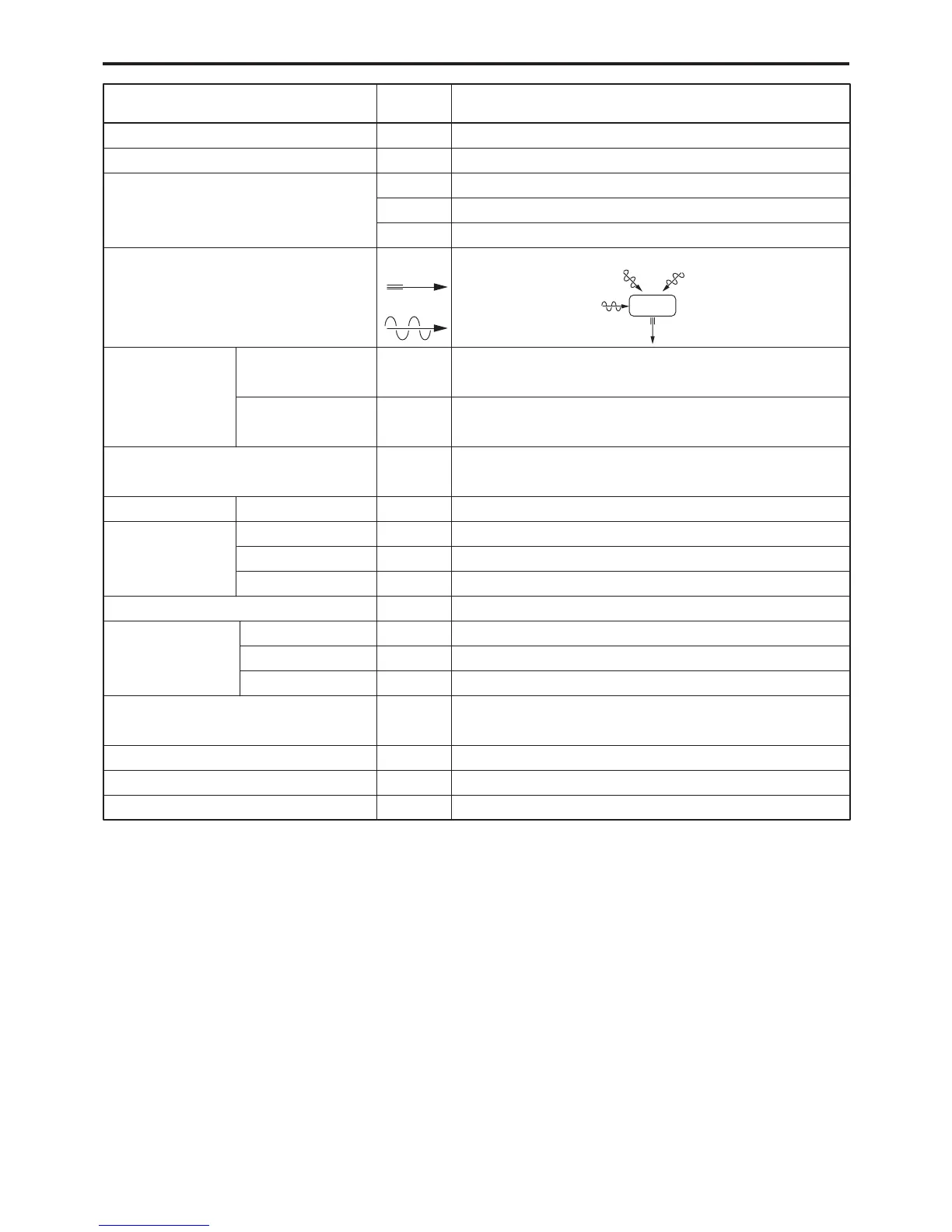

If there is a gas leakage, you should not only refill the required amount of the refrigerant gas but also find out the gas leakage point and mend it. If the service work has to be suspended before mending the leakage points, be sure to collect the refrigerant gas in the unit by using pump then fasten the service ports to avoid any further leakage. Note that poisonous gas may be generated when the leaked refrigerant is exposed to fire.