– 62 –

Speed/Hall Sensor Removal

Disconnect the speed/hall sensor from the drive

motor and disconnect from the main harness.

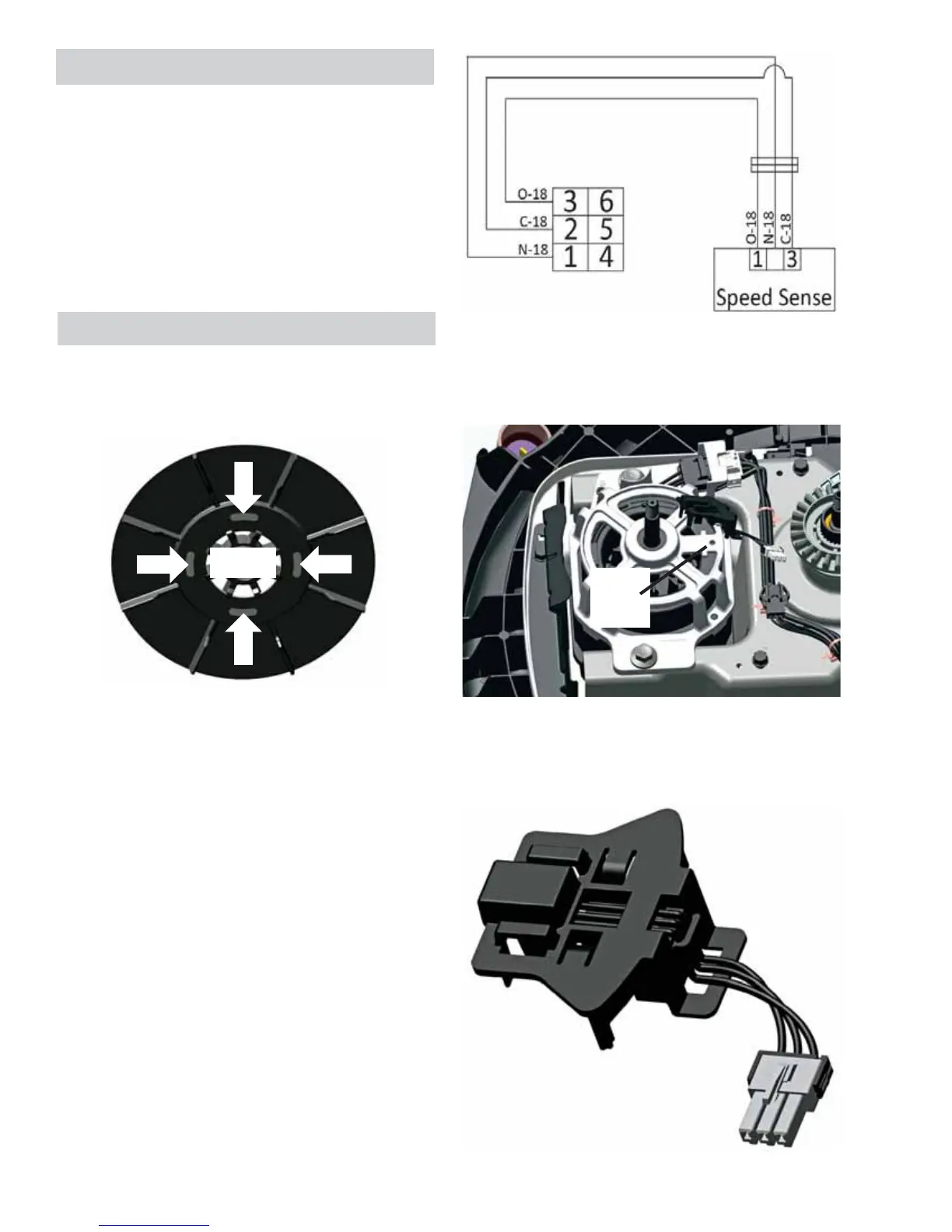

There is a locating post on the bottom of the sensor

that is pushed into an existing hole in the motor

housing, when reinstalling.

Pulley Removal

1. Remove the two 9/16 nuts (one for each pulley),

securing them to the motor and transmission

shafts.

2. 6OLGHWKHSXOOH\VRȺWKHPRWRUDQGWUDQVPLVVLRQ

shafts. Torque the new pulley nut to 110 in. lb.

when reinstalling.

Drive/Transmission Pulleys Cont.

Speed/Hall Sensor

The speed/hall sensor is mounted to the drive motor

and sends a pulse signal back to the control board.

This is done when the magnet that is mounted in the

drive motor pulley pass over the sensor.

If the control does not read any signal from the

sensor from the movement of the motor, the washer

cycle will stop.

Diagnosing the Speed/Hall Sensor

The speed/hall sensor can be diagnosed two

GLȺHUHQWZD\V

• Enter the Service Mode and Run the Spin Test

If the speed/hall sensor is bad or disconnected,

WKHEDVNHWZLOOVWDUWWRVSLQQRUPDOO\DW¿UVW

After 5 seconds, motor power will be stopped

and a locked rotor fault will be set. If the washer

continues to spin for at least 15 seconds, the

speed/hall sensor is good.

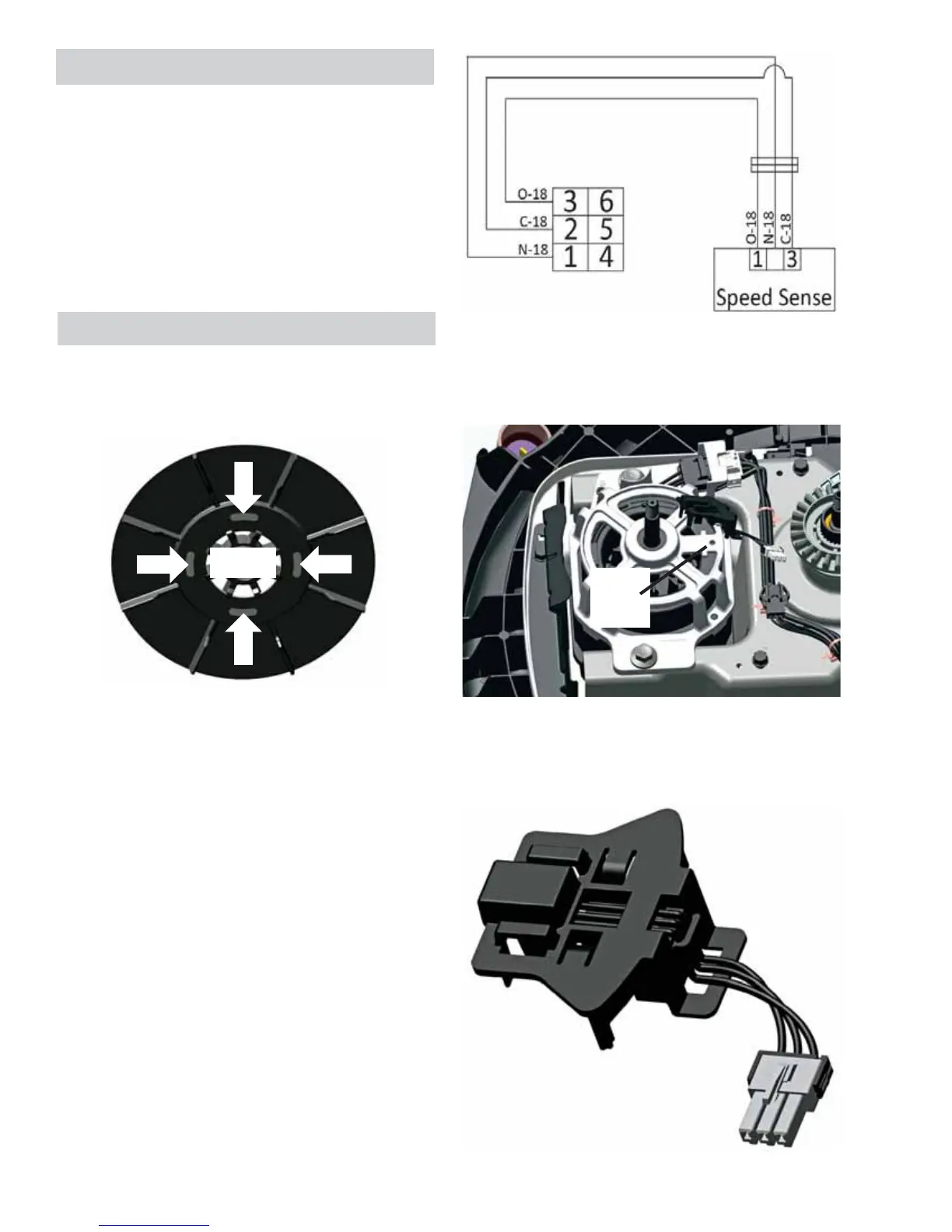

• Test the Voltage

From connector pins 3 through 5 on the J602

should read approximately 9 VDC.

Pins 1 through 5 should read approximately 4.5

VDC while rotating the basket.

Magnet

Guide

post

hole

Loading...

Loading...