653, 654

12 / 28

11.3 Setting the seal adjuster

and the stroke limiter

Important:

Only set the seal adjuster and

stroke limiter when the valve

is completely assembled (with

diaphragm and valve body) and in

a cold condition!

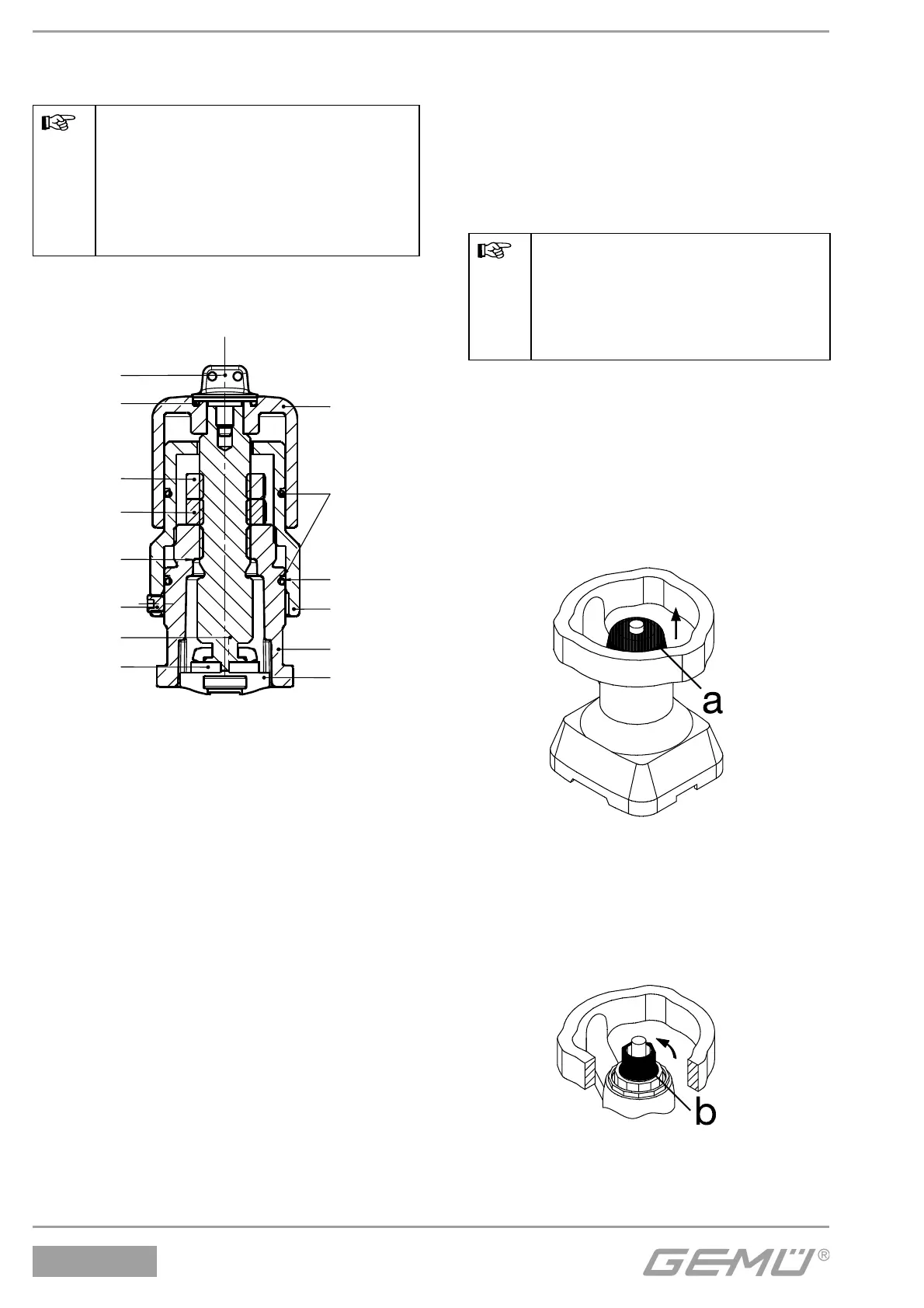

GEMÜ 654 bonnet size 0TH

Diaphragm size 8

15

4

Greased

thread

9

3

10

Greased

O-rings

5

12

7

6

13

11

8

Setting the seal adjuster

G Unscrew locking screw 8 and remove it.

G Pull off handwheel 7.

G Loosen locking screw 9 with a SW2 Allen

key (do not unscrew it completely).

G Unscrew stroke limiting sleeve 5 and

remove it.

G Loosen lock nut 6 with a SW19 open-end

wrench and unscrew it by 2 to 3 turns.

G To deactivate the seal adjuster loosen the

seal adjuster nut 13 with a SW19 open-

end wrench unscrew it by 2 to 3 turns.

G Place handwheel 7 upside down on the

double flats of the threaded spindle 15.

Gently close the valve with handwheel 7

("CLOSED position") (valve is tight).

G Screw in the seal adjuster nut 13 until it

stops and secure with lock nut 6 (SW19

open-end wrench).

Setting the stroke limiter

G Move the valve to the OPEN position by

turning handwheel 7 (upside down) until

the required flow rate is reached.

G Pull of handwheel 7 from the threaded

spindle 15.

G Screw stroke limiting sleeve 5 on until it

stops.

Important:

The threaded spindle 15 must

not turn during this process!

If necessary, hold with a SW8

open-end wrench!

G Fix the stroke limiting sleeve 5 with

locking screw 9 (SW2 Allen key).

G Push handwheel 7 into its original

position on the double flats of the

threaded spindle 15 and secure it with

locking screw 8.

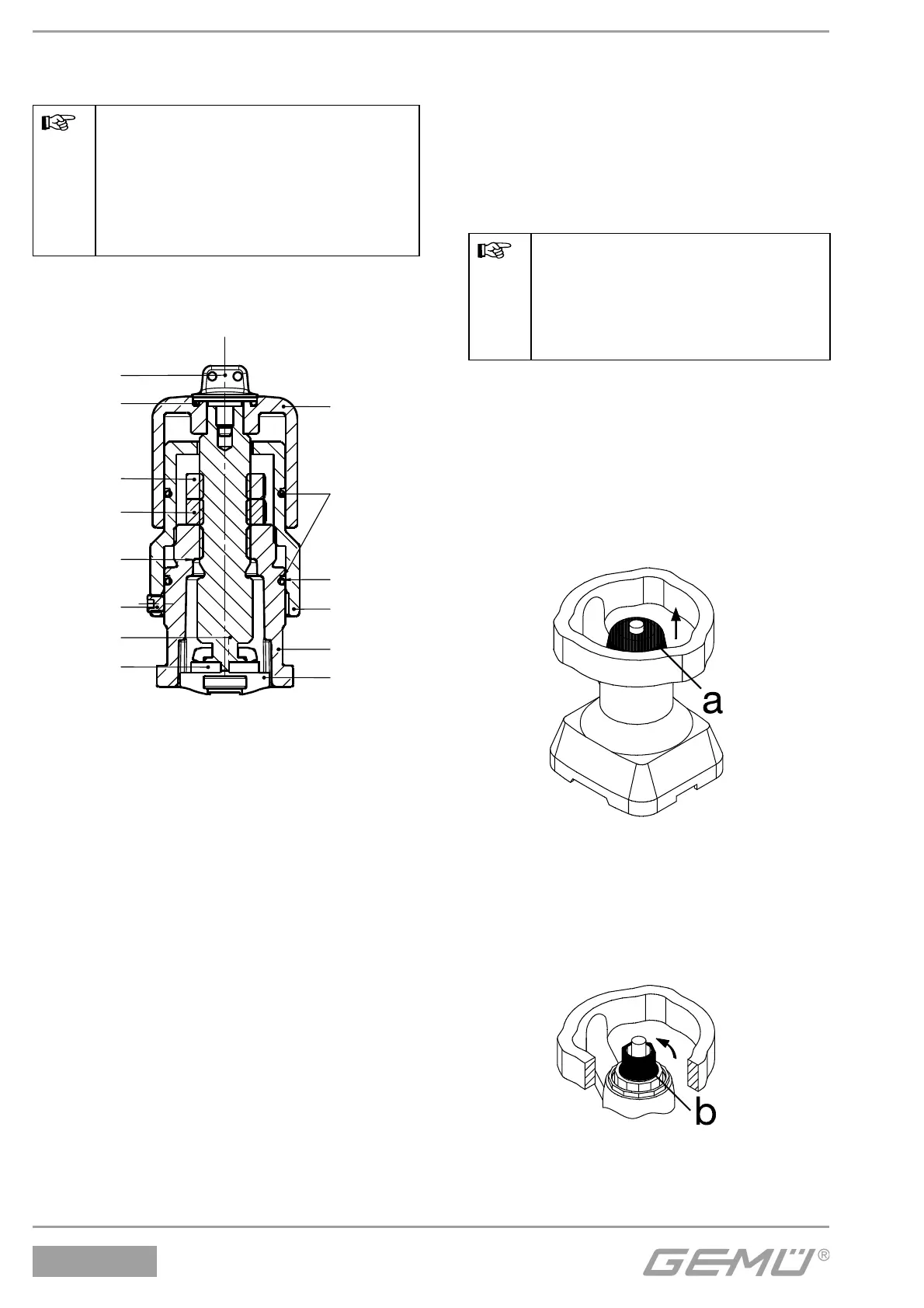

Diaphragm sizes 10 - 50

Preparation for setting

G Remove protective cap a.

G Move the bonnet out of the end positions

to enable the handwheel to be turned in

both directions.

Releasing the stroke limiter

G Turn stroke limiter b anticlockwise

upwards until the male thread is visible.

Loading...

Loading...