www.gemu-group.com14 / 19GEMÜ Q30

10 Inspection and maintenance

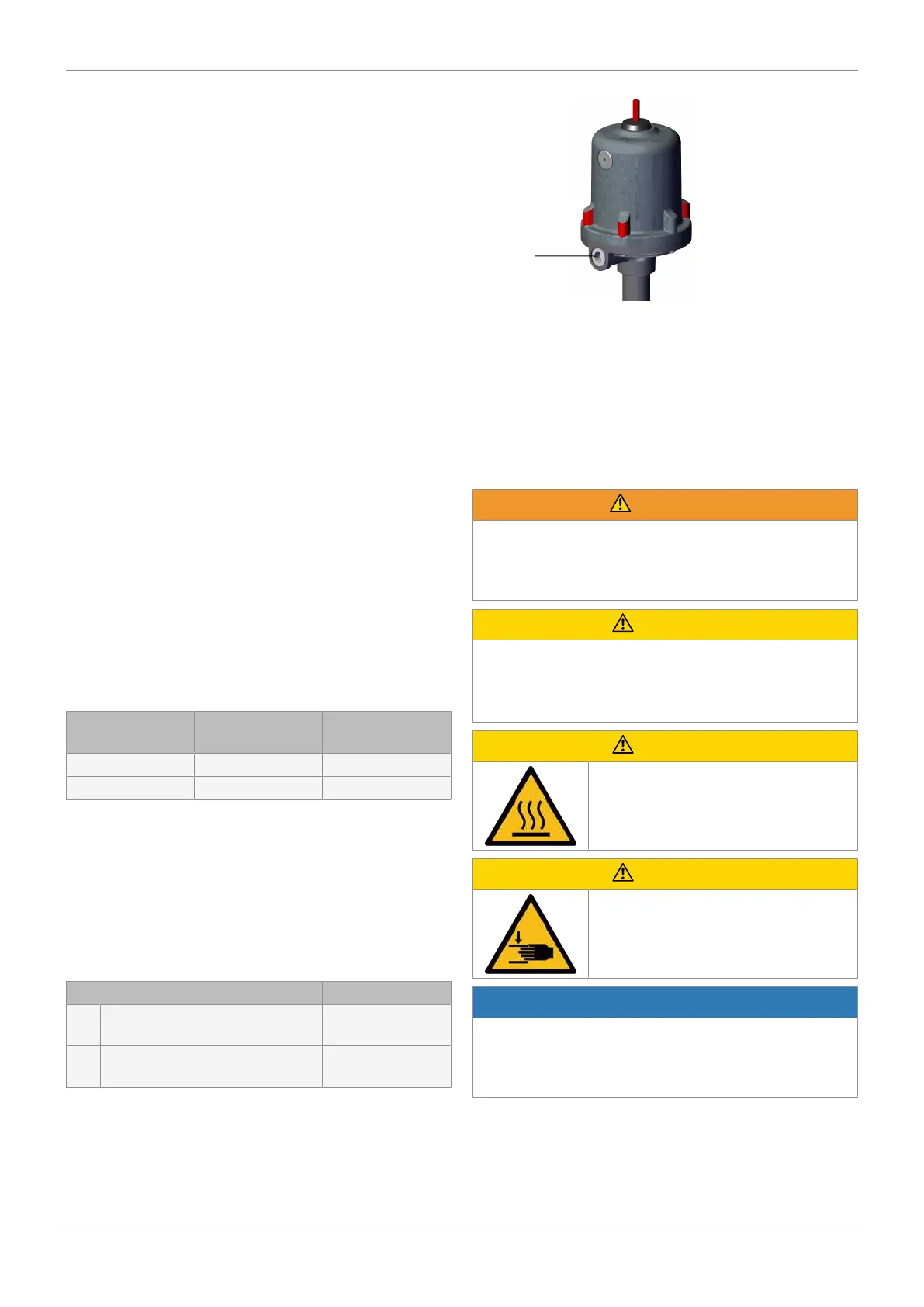

9.3 Mounting without mounting flange

1. Before mounting the valve body, machine the housing in

accordance with the borehole pattern in the chapter "Di-

mensions" so that the valve body can be secured to the

housing.

2. Secure the valve body to the housing using four screws.

3. Re-attach or reactivate all safety and protective devices.

9.4 Mounting with mounting flange

1. Before mounting the actuator, machine the housing in ac-

cordance with the borehole pattern in the chapter "Dimen-

sions" so that the valve body can be guided through the re-

cess.

2. Guide the valve body through the recess in the housing.

The actuator's mounting flange must be flush with the

housing.

3. Connect the mounting flange and housing using appropri-

ate screws and washers (not included in the scope of de-

livery).

9.5 Pneumatic connection

The following types are available:

Normally closed (NC):

Actuator resting position: closed by spring force. Activation of

the actuator (connector 2) opens the actuator. When the actu-

ator is vented, the actuator is closed by spring force.

Normally open (NO):

Actuator resting position: opened by spring force. Activation

of the actuator (connector 4) closes the actuator. When the

actuator is vented, the actuator is opened by spring force.

Control function Control medium

connector 2 (open)

Control medium

connector 4 (close)

1 (NC) + -

2 (NO) – +

+ = available

– = not available

9.5.1 Connecting the control medium

1. Use suitable connectors.

2. Connect the control medium lines tension-free and

without any bends or knots.

Thread size of the control medium connectors: G1/4

Control function Connections

1 Normally closed (NC) 2: Control medium

(open)

2 Normally open (NO) 4: Control medium

(close)

3. If necessary, remove blanking plugs from the control me-

dium connectors.

4. Control function 1: Screw the control medium line into

control medium connector 2 of the actuator.

5. Control function 2: Screw the control medium line into

control medium connector 4 of the actuator.

10 Inspection and maintenance

WARNING

The equipment is subject to pressure!

▶ Risk of severe injury or death.

● Depressurize the plant.

● Completely drain the plant.

CAUTION

Use of incorrect spare parts!

▶ Damage to the GEMÜ product.

▶ Manufacturer liability and guarantee will be void.

● Use only genuine parts from GEMÜ.

CAUTION

Hot plant components!

▶ Risk of burns.

● Only work on plant that has cooled

down.

CAUTION

Risk of crushing!

▶ Risk of severe injury!

● Before performing any work on the

GEMÜ product, depressurize the plant.

NOTICE

Requirements for tube lines used!

▶ Use tube lines suitable for the application, see manufac-

turer's information.

● Only use undamaged tube lines.

Loading...

Loading...