,167$//$7,21

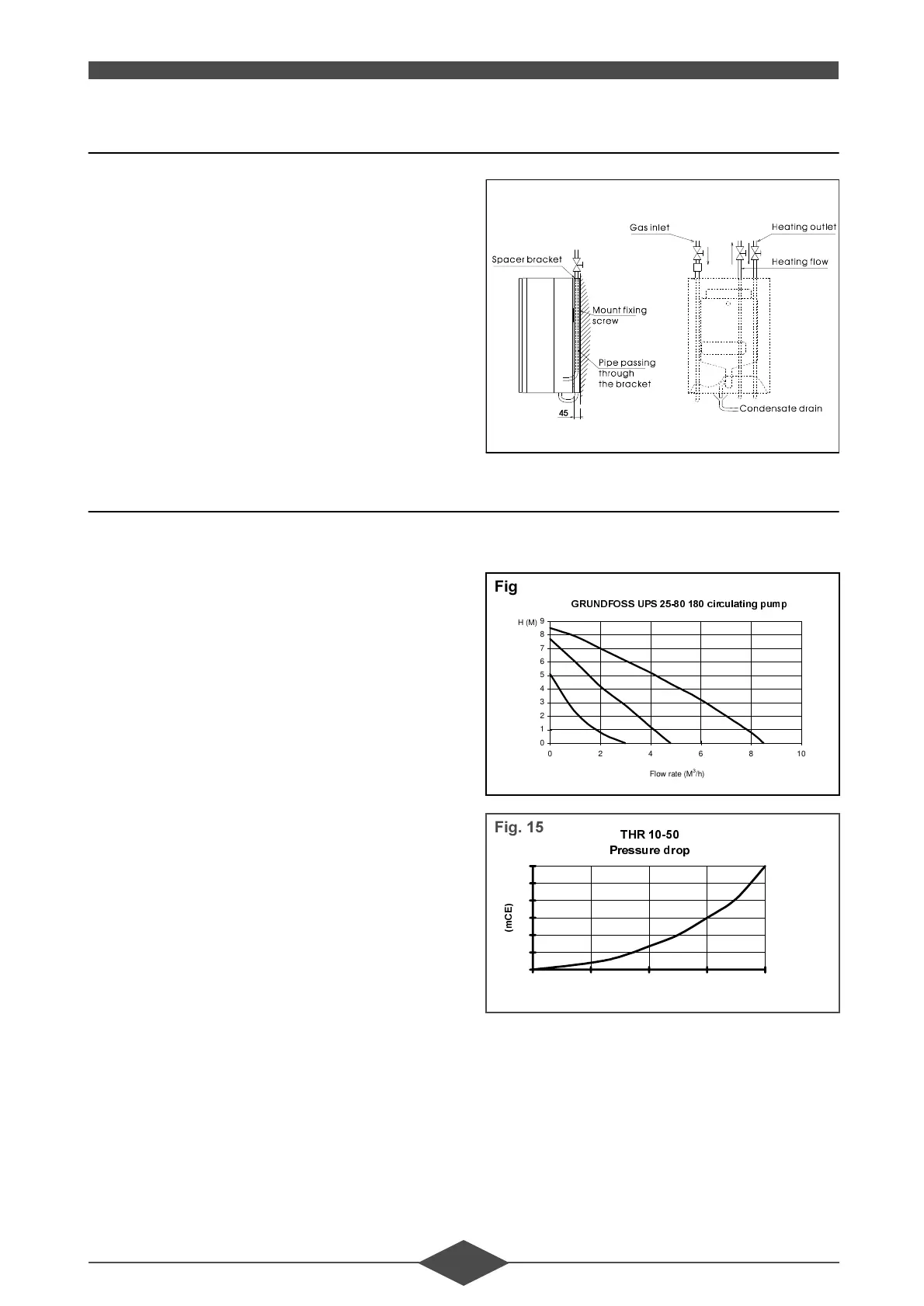

63$&(5%$&.3/$7(6833/,('$6$1237,21

The spacer back plate allows the pipes to be fed

through behind the boiler when they arrive from

above.

Assembly:

- Fit the angle mounting to the wall (supplied with

the boiler).

- Hang the spacer back plate on the angle mount-

ing.

- Hang the boiler on to the spacer back plate.

3/80%,1*&211(&7,216

Accessories to be connected:

- Expansion vessel (an option) precharged to

0.5 bar suitable for an installation up to 100 litres.

(For more than 100 litres provide for additional

expansion).

- Heating system safety pressure relief valve for

connecting to the waste water outlet via a funnel

and siphon trap.

- Condensate drainage siphon trap for connect-

ing via Ø 25 PVC pipe to the waste water outlet

via a funnel and siphon trap. When installing the

system, don’t forget to fill the siphon traps with

water before commissioning. These should be in-

spected twice a year.

-A circulating pump with an air vent. The silicon

tube from the purger should be slid inside the fun-

nel.

The heating flow and return pipes must be fitted with

stop valves so that work can be carried out on the

boiler if required without draining the installation.

:DWHUIORZUDWHWKURXJKWKHKHDWH[FKDQJHU

The power delivered by the boiler depends on the

water flow rate through the exchanger. This can be

set to between 1200 and 2500 litres/hour according

to the installation’s rated power output.

To ensure that heat transfer operates correctly and

to avoid any risk of boiling, never use a flow rate of

less than 1200 litres/hour.

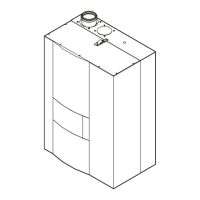

3UHVVXUHIORZUDWHFXUYHV

)LJ

*581')266836FLUFXODWLQJSXPS

0

1

2

3

4

5

6

7

8

9

0246810

Flow rate (M

3

/h)

H (M)

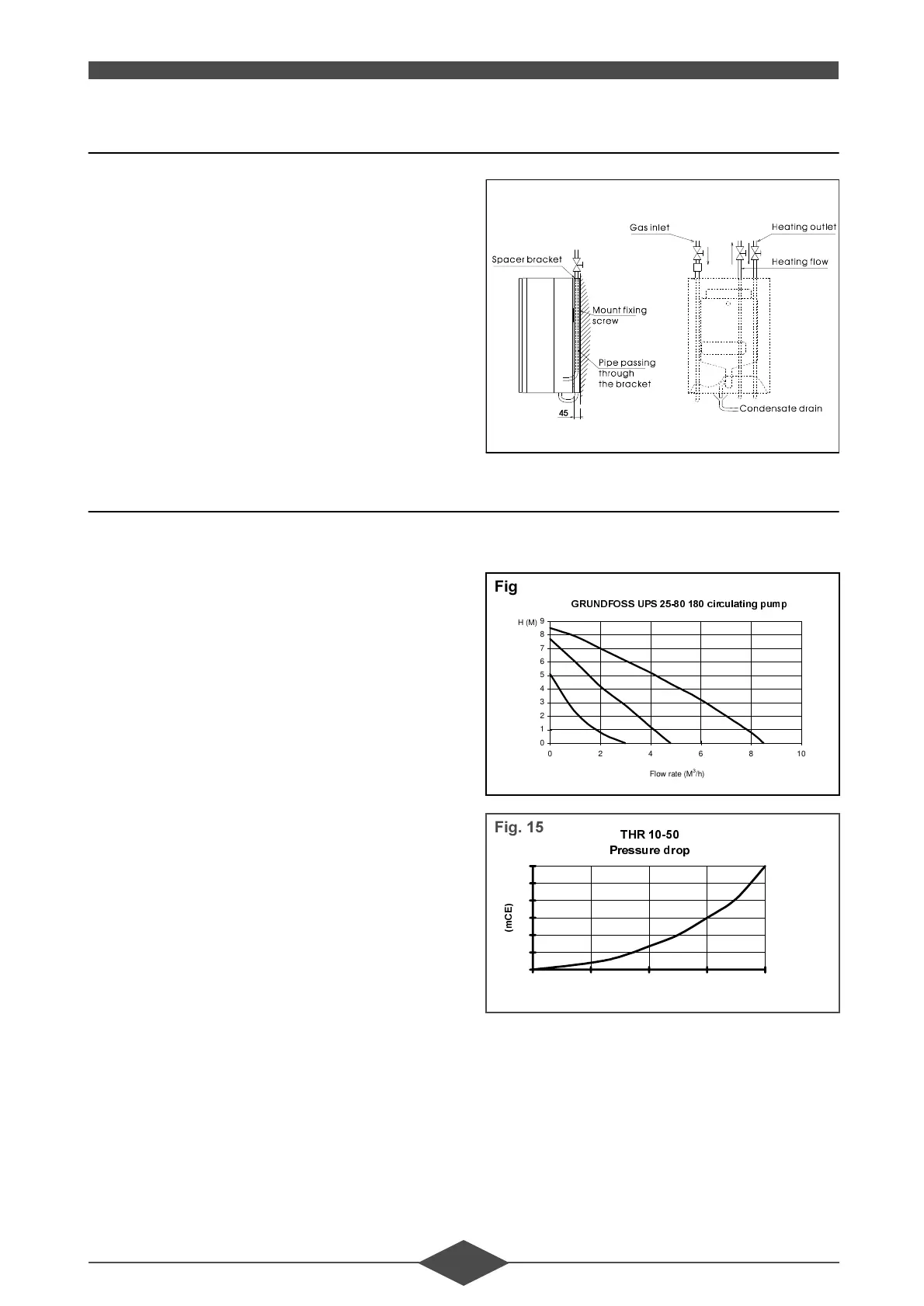

)LJ

7+5

3UHVVXUHGURS

0

1

2

3

4

5

6

0 500 1000 1500 2000

Flow rate (dm

3

/ h)

P

&

(

)LJ

Loading...

Loading...