10-2

SECTION 10: CYLINDER & CRANKCASE COVER

It is recommended that the cylinder bores be reconditioned

to restore the cross hatch when new piston rings are to be

installed in a cylinder that is within specification. Be careful not

to hone oversize or it will be necessary to replace the crankcase.

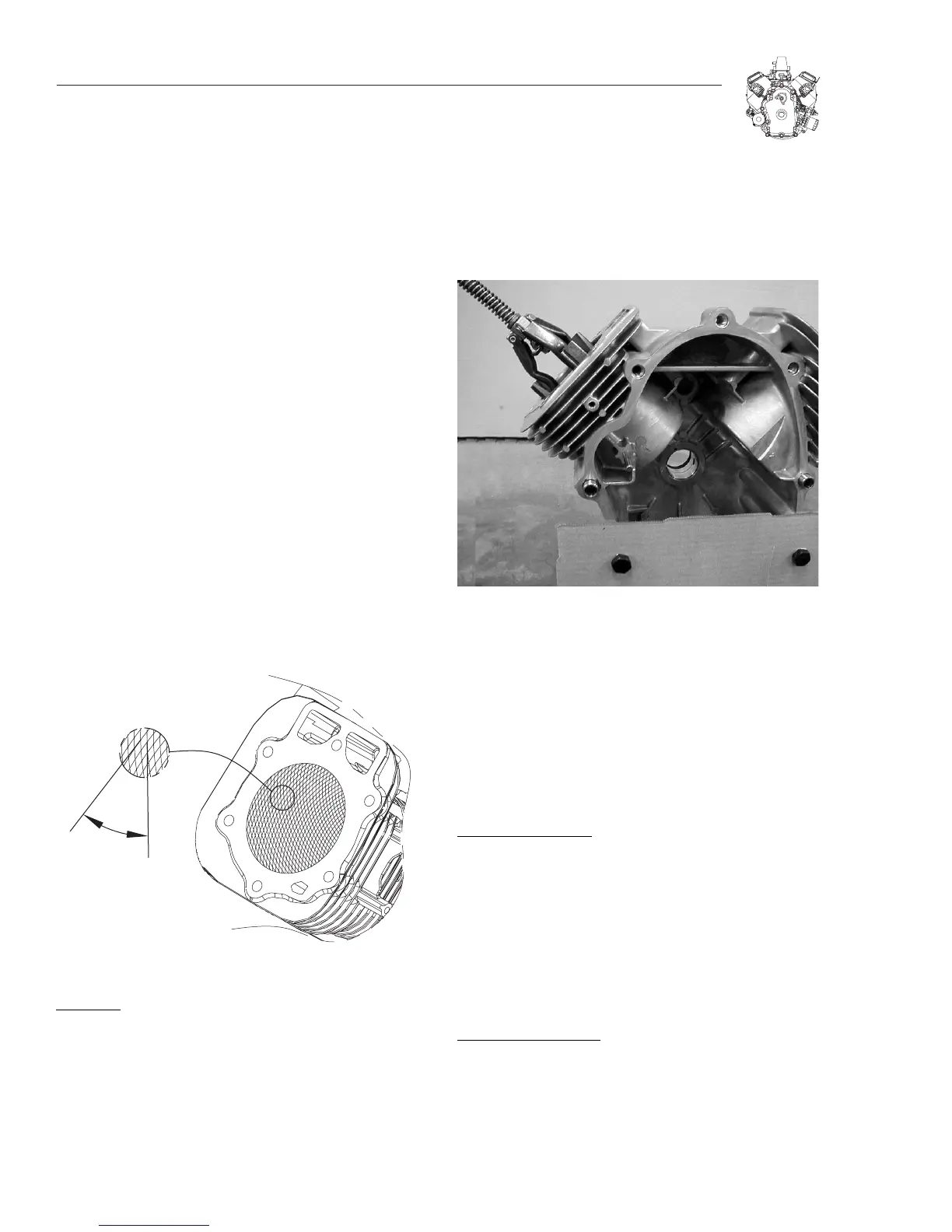

Honing is done with a variable speed 1 /2", portable drill and

a honing fixture. See Page 10-5 for dimensions to make a

honing fixture. Use two crankcase cover mounting screws to

fasten the crankcase to the honing fixture, Figure 10-5.

Clamp honing fixture and crankcase securely in a vise at a

convenient work height.

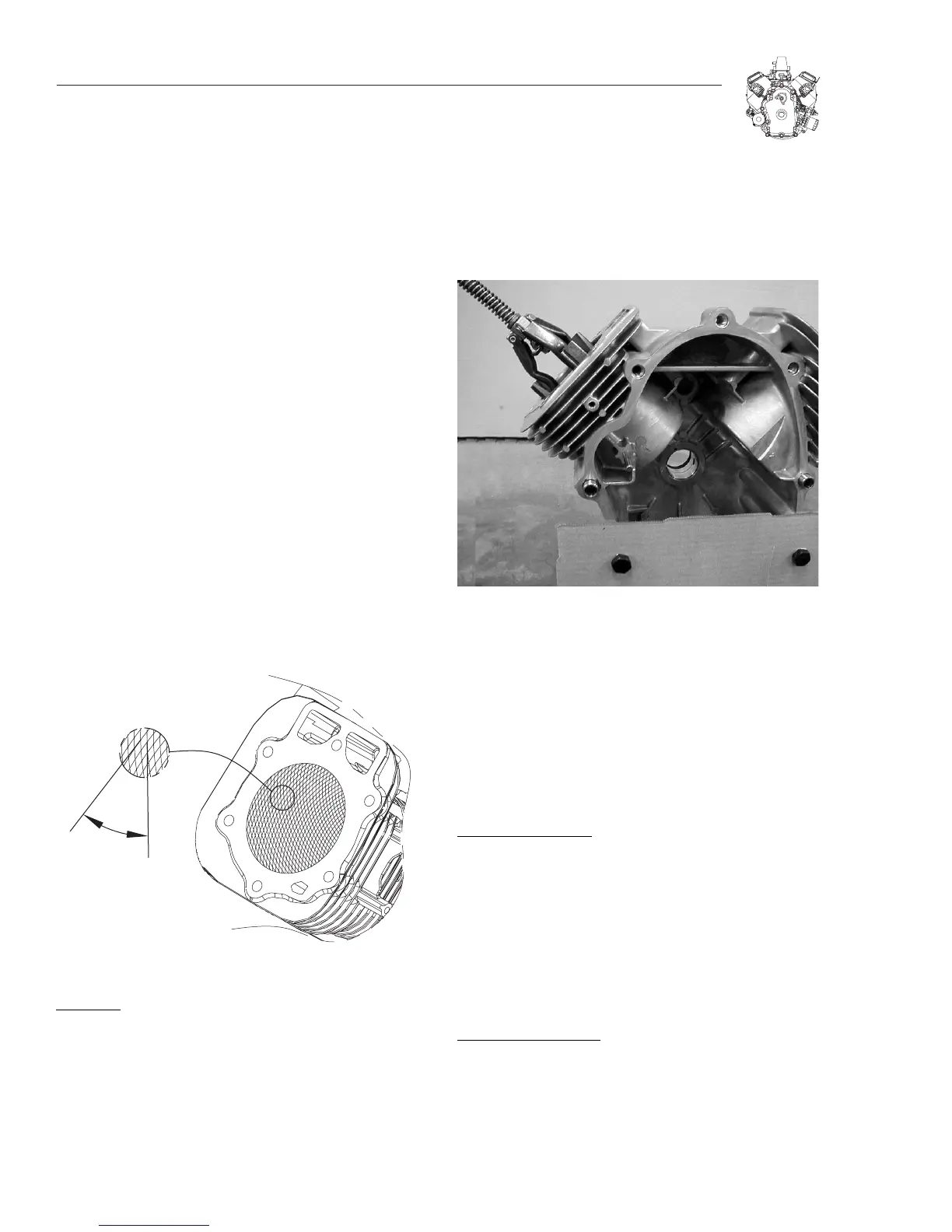

Place hone in middle of cylinder bore. Tighten adjusting

knob with finger until stones fit snugly against cylinder wall.

DO NOT FORCE. Cut a wood block and place inside cylinder

to prevent hone from extending further than 3/4" to 1" (19

mm to 25 mm) below cylinder bore. Place hone drive shaft in

chuck of portable drill and tighten. Be sure that cylinder and

hone are centered and aligned with the drill spindle.

NOTE: To produce the proper cross hatch finish use a drill

speed of approximately 200 RPM and 40-60 Hatch strokes

per minute. Lubricate hone liberally to prevent build up

on finishing stones.

NOTE: Automatic transmission fluid is an acceptable

honing oil. Another acceptable honing oil can be made

by mixing 4 parts No. 30 weight oil with 1 part kerosene.

Figure 10-4. Cylinder Cross

CLEANING:

IT IS MOST IMPORTANT THAT THE ENTIRE CYLINDER AND

CRANKCASE BE THOROUGHLY CLEANED AFTER HONING.

First wash the cylinder and crankcase carefully in a solvent such as

kerosene or commercial solvent. Then thoroughly wash cylinder and

crankcase using a stiff brush with soap and hot water. Rinse thoroughly

with hot running water. Repeat washing and rinsing until all traces

of honing grit are gone.

Honing grit is highly abrasive and will cause rapid wear to all

of the internal components of the engine unless it is completely

removed.

Figure 10-5. Honing Cylinders

NOTE: When cylinder and crankcase have been thor-

oughly cleaned, use a clean white rag or napkin and

wipe the cylinder bore. If honing grit is present it will

appear as a gray residue on rag. If any honing grit is evi-

dent, re-wash and rinse entire cylinder and crankcase and

check again. When there is no trace of honing grit on rag,

the cylinder is properly cleaned. Then oil cylinder bore

to prevent rusting.

BEARINGS

CHECK MAG BEARING:

Check magneto bearing for damage. Damaged bearings

must be replaced. If not damaged, check for wear using a tele-

scoping gauge and caliper (see Figure 10-6). Measure at several

locations. If the measured diameter is larger than 38.25 mm

(1.506”), the bearing must be replaced.

The diameter of the crankshaft may also make it necessary

to replace the bearing. See Section 11 for the crankshaft mea-

surement details.

REMOVE MAG BEARING:

1.Remove seal.

2.Place crankcase flat upon a press and remove bearing using

a bushing driver (Figure 10-7).

Loading...

Loading...