AD J USTING BELT TENSION

1. REMOVE UPPER ACCESS PANEL: Remove all ¼” bolts holding the Upper

access panel with a 3/8” socket and ratchet. The panel is sealed with Loctite 598

High Performance RTV Silicone Gasket Maker. The panel will need to be pried

from the frame with a large screwdriver.

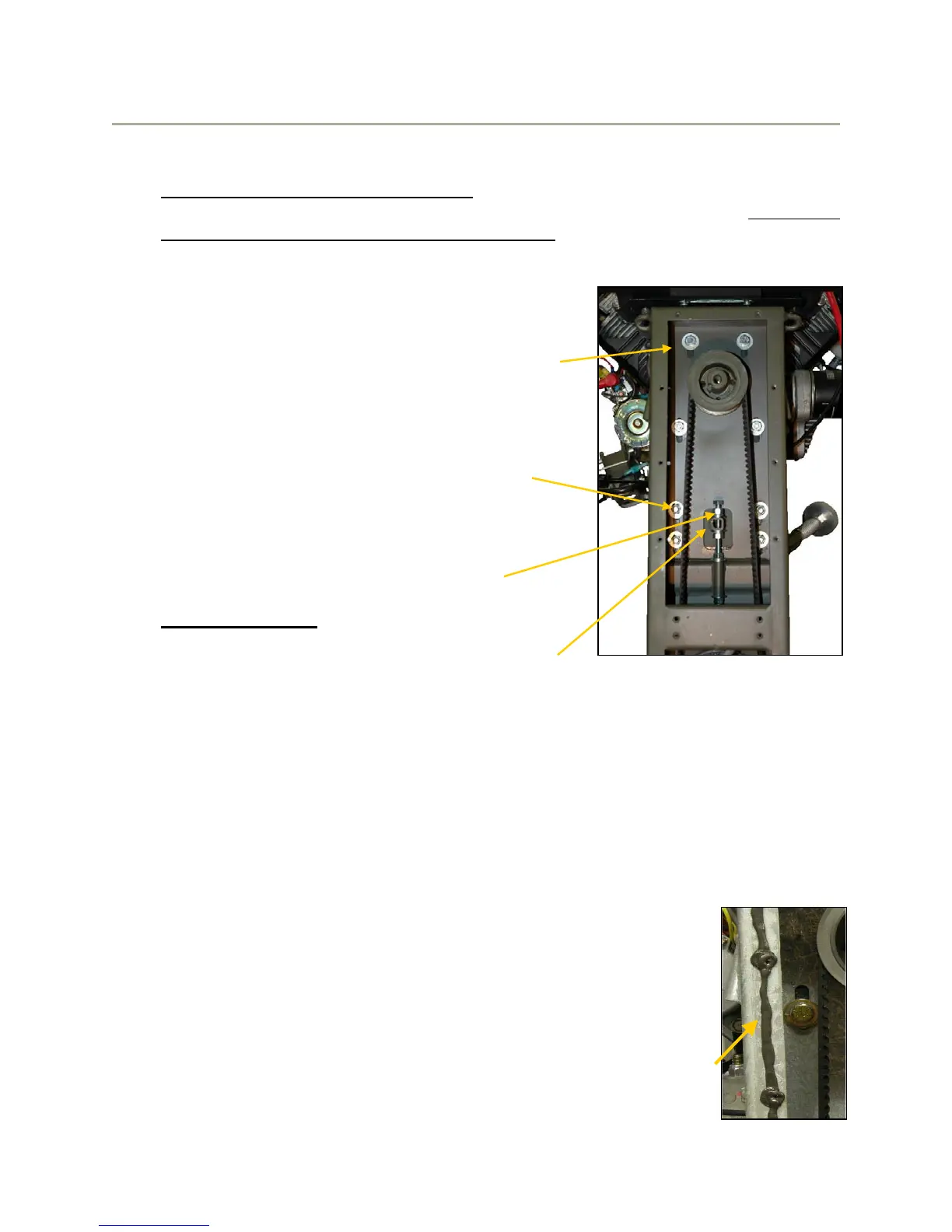

2. Locate the 3/8” bolts shown in the photo to the

right. Using a 9/16” socket, ratchet and extension,

loosen the top 4 bolts around the engine

crankshaft. Hand tighten the bolts to allow the

frame to slide up and down but remain against the

engine.

3. Loosen the lower 4 bolts using the ratchet and

9/16” wrench. Snug the bolts as done for

the upper bolts to allow the frame to slide

up and down.

4. Loosen the Upper Tension Adjustment nut on the

jack bolt using a 9/16” open end wrench.

5. NEW BELT ONLY - If installing a new belt, loosen

the Lower adjustment nut and turn the Upper

adjustment nut clockwise to loosen the belt.

Remove all four of the 3/8” bolts securing the sprocket shaft bearing housing

shown on page 12. The sprocket unit can then be lifted enough to change the

belt. Apply Blue Loctite to bolts and reinstall them with the new belt in place

around the sprocket. Torque all four bolts to 250 In.-Lbs. (21 Ft.-Lbs.)

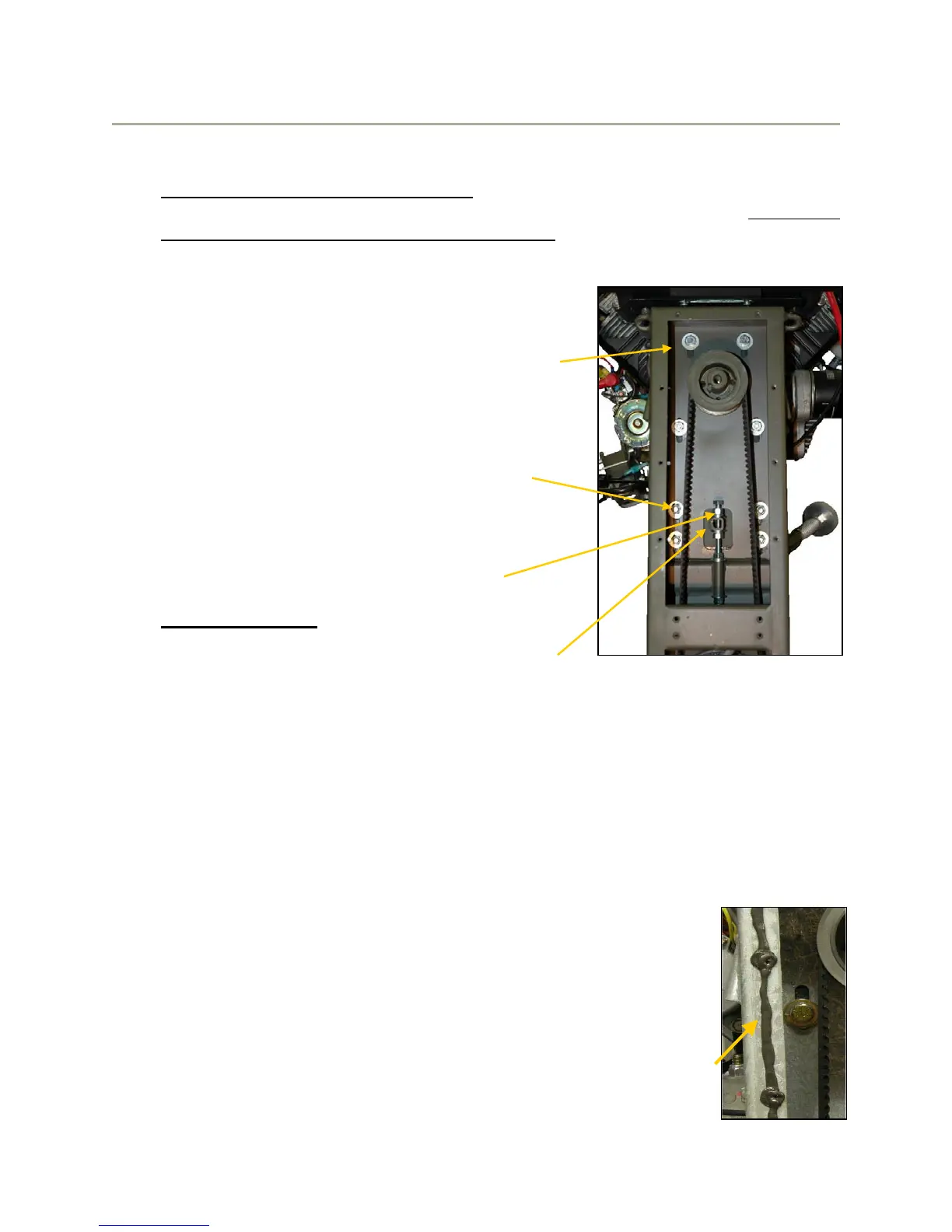

6. To increase belt tension, turn the Lower Tension Adjustment nut counterclockwise

until the proper tension is achieved as indicated by the tension gauge instructions

listed on page 14.

7. Tighten all 8 of the 3/8” bolts shown above to 250 In.-Lbs. (21 Ft.-Lbs.)

8. Tighten the Upper Tension adjustment nut.

9. After tightening all bolts and nuts listed above, check belt tension

again and readjust if necessary using the same procedures.

Replace the inspection hole plug when finished.

10. Remove existing RTV Silicone from frame and access panel and

insure that mating surfaces are clean. Apply a continuous 1/8”

bead of silicone to the frame surface and inside the bolt holes.

Ensure that the bead is continuous around the perimeter to

Loading...

Loading...