Maintenance

Flush Flush

Flush

Inlet Inlet

Inlet

Strainer Strainer

Strainer

Screen Screen

Screen

Theinletstrainerslteroutparticlesthatcan

plugthepumpinletcheckvalves.Inspectthe

screensdailyaspartofthestartuproutine,and

cleanasrequired.

Isocyanatecancrystallizefrommoisture

contaminationorfromfreezing.Ifthechemicals

usedarecleanandproperstorage,transfer,and

operatingproceduresarefollowed,thereshould

beminimalcontaminationoftheA-sidescreen.

CleantheA-sidescreenonlyduringdaily

startup.Thisminimizesmoisturecontamination

byimmediatelyushingoutanyisocyanate

residueatthestartofdispensingoperations.

1.Closetheuidinletvalveatthepumpinlet

andshutofftheappropriatefeedpump.

Thispreventsmaterialfrombeingpumped

whilecleaningthescreen.

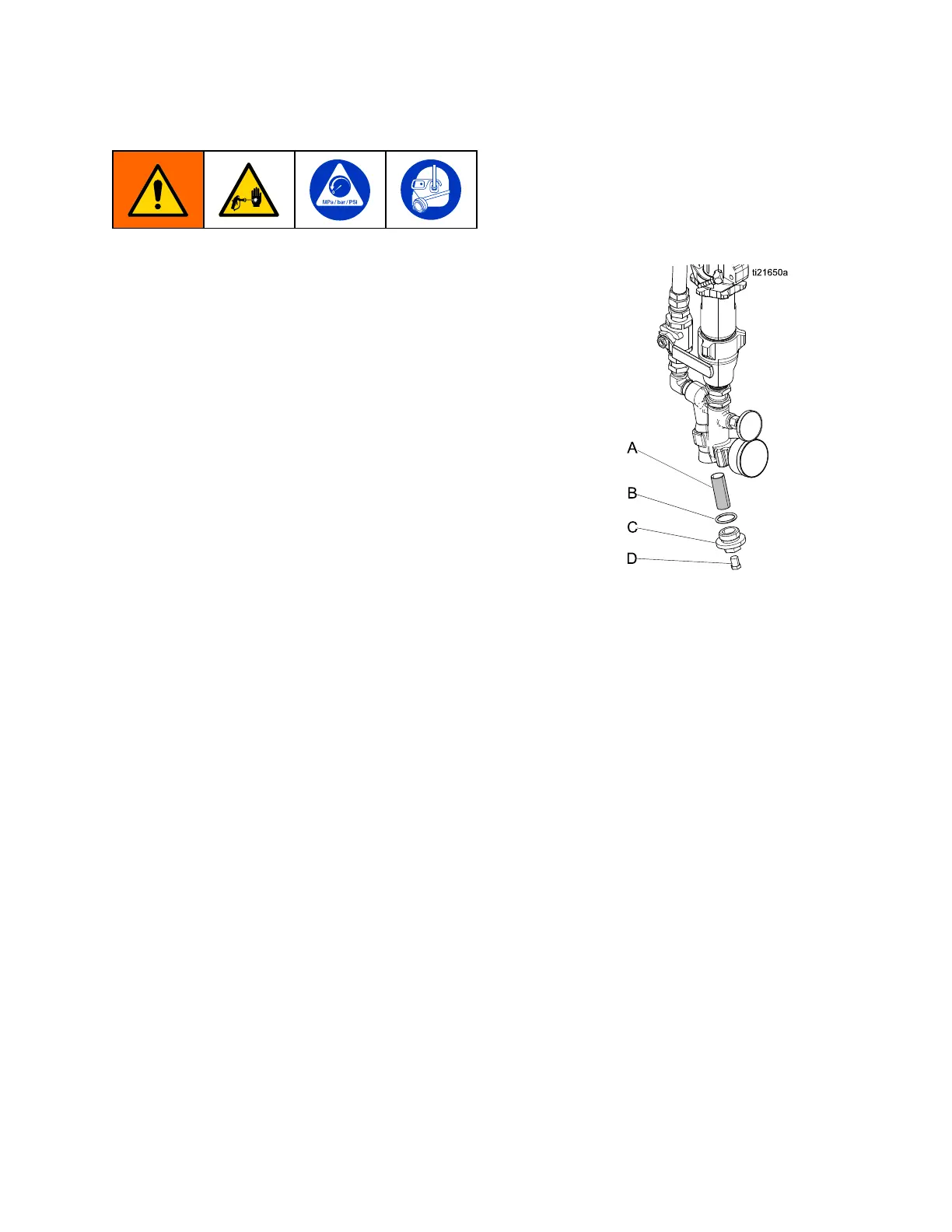

2.Placeacontainerunderthestrainerbaseto

catchdrainoffwhenremovingthestrainer

plug(C).

3.Removethescreen(A)fromthestrainer

manifold.Thoroughlyushthescreenwith

compatiblesolventandshakeitdry.Inspect

thescreen.Nomorethan25%ofthemesh

shouldberestricted.Ifmorethan25%ofthe

meshisblocked,replacethescreen.Inspect

thegasket(B)andreplaceasrequired.

4.Ensurethepipeplug(D)isscrewedintothe

strainerplug(C).Installthestrainerplug

withthescreen(A)ando-ring(B)inplace

andtighten.Donotovertighten.Letthe

gasketmaketheseal.

5.Opentheuidinletvalve,ensurethatthere

arenoleaks,andwipetheequipmentclean.

Proceedwithoperation.

Figure15

333023U 65

Loading...

Loading...