13

Test the safety valve at least twice each month.

The pressure gauge should show a vacuum of 20

to 30 inches when the kettle is cold.

If steam pressure greater than 50 PSI is generated in

the jacket, the safety valve will open and relieve the

excess pressure.

If the jacket water level gets too low and the heating

elements overheat, the high-limit control will open,

shutting off power to the elements until the kettle cools.

Setting the operating thermostat dial to “OFF” shuts

down all control and heating circuits.

Maintenance

NOTICE: Contact Groen or an authorized Groen representative when repairs are required.

1. Periodic Maintenance

A Maintenance & Service Log is provided at the

back of this manual. Each time maintenance is

performed on your Groen kettle, enter the date of

the work, what was done, and who did it. Keep this

manual on file and available for operators to use.

Periodic inspection will minimize equipment down

time and increase the efficiency of operation. The

following points should be checked:

[BY OPERATOR]

a. Check the pressure/vacuum gauge every day.

The gauge should show a vacuum of 20 to 30

inches, when the kettle is cold. If it does not,

see “Jacket Vacuum” on page 14.

b. Also check the jacket water level each day. It

should be above mid point of the round sight

glass. If the level is low, see “Jacket Filling and

Water Treatment” on page 14.

[BY SERVICE TECHNICIAN]

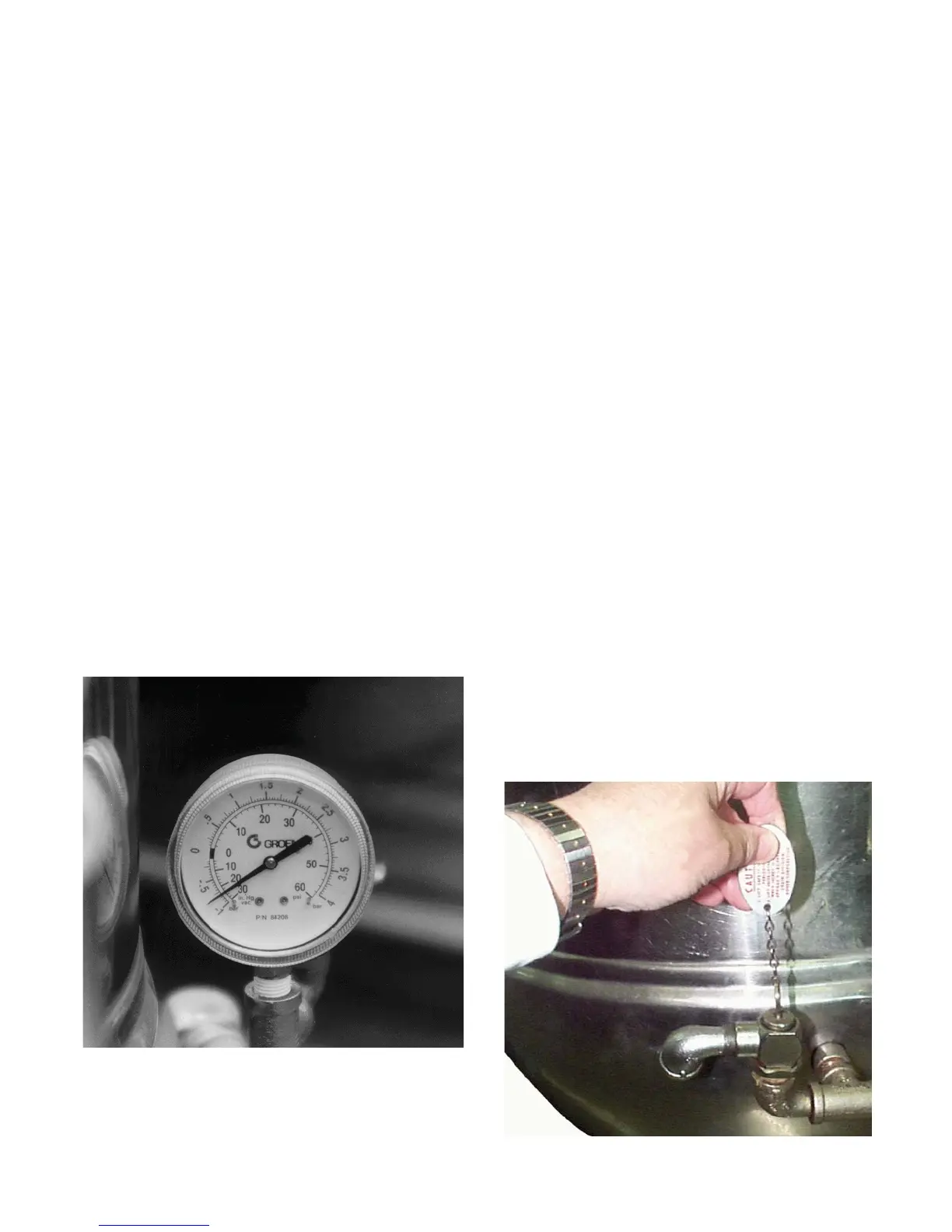

c. Test the safety valve at least twice each

month. Test the valve with the kettle

operating at 15 psi (105 kPa), by pulling up

the test chain for at least five seconds. Then

release the chain and let the valve snap

shut. If the valve does not activate, (there is

no evidence of discharge, or the valve

leaks) stop using the kettle immediately and

contact a qualified Groen service

representative.

d. The inside of the support housing should be

kept clean.

e. At least twice a year, grease the two

trunnion bearings. The bearings are located

within the kettle support housing. Remove

the access panels from the support housing

with a screwdriver to gain access to the

grease fittings. Use a lithium-based, multi-

Loading...

Loading...