8

Installation

The Groen Kettle is provided with

complete internal wiring. It is ready for

immediate connection. A wiring diagram

is provided in this manual and on the

inside of the control housing service

panel. Any mechanical or electrical changes must

be approved by Groen’s Food Service Engineering

Department.

WARNING

INSTALLATION OF THE KETTLE MUST

BE DONE BY PERSONNEL QUALIFIED TO

WORK WITH ELECTRICITY. IMPROPER

INSTALLATION CAN RESULT IN INJURY

TO PERSONNEL AND/OR DAMAGE TO

EQUIPMENT.

The completed unit has been operated at the factory

to test all controls and heater elements.

1. Set the kettle in place and level it. The base

should be securely fastened to a table or work

surface. Four 3/8”-16 N.C. threaded couplings

are provided in the base of unit. Installation

under a ventilation hood is recommended.

2. Provide electrical power as specified on the

electrical information plate attached to the

equipment. Observe all local and national

codes, and all regulations in force at the time

of installation.

3. The equipment is shipped ready for three

phase operation. Refer to the wiring diagram

for single phase operation.

4. Bring the electrical service through the

entrance at the rear of the support housing,

making a watertight connection with the

incoming lines. (A BX connection is not

recommended.) Observe all local and

national codes, and all regulations in force at

the time of installation.

DANGER

ELECTRICALLY GROUND THE UNIT AT

THE TERMINAL PROVIDED. FAILURE TO

GROUND UNIT COULD RESULT IN

ELECTROCUTION AND DEATH.

5. Confirm that the jacket water level is above

mid point of sight glass. If the level is low,

follow the instructions under “Jacket Filling

and Water Treatment,” Page 14.

6. Electrically earth the unit at the terminal

provided.

7. Equipotential terminal: In accordance with

national regulations, the unit has been fitted

with an equipotential terminal.

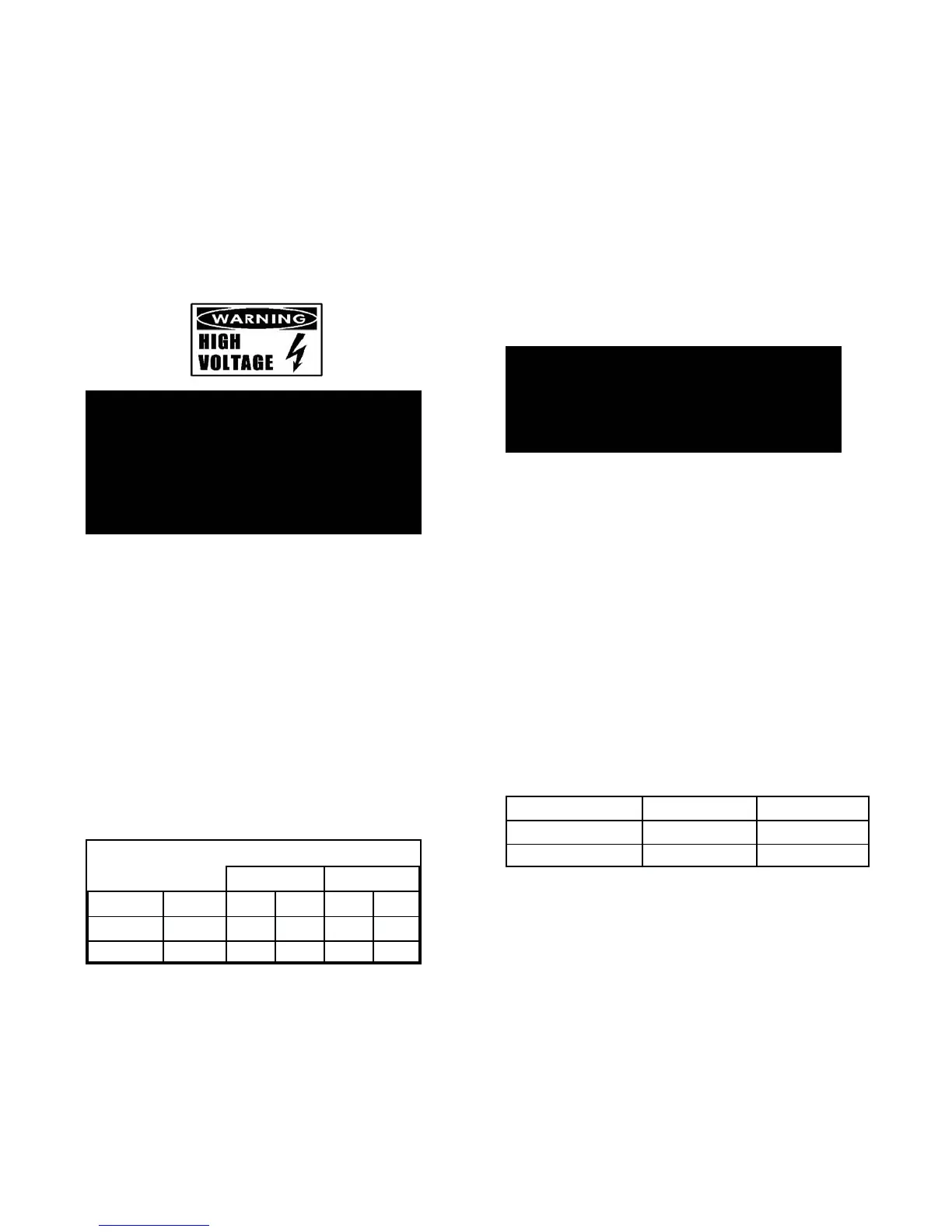

TDB(C) ELECTRICAL SPECIFICATIONS

20 QUARTS 40 QUARTS

VOLTAGE PHASE KW AMPS KW AMPS

230 1 7.8 33 13.3` 57

400 3 7.8 11.2 13.3 19

ELECTRICAL SUPPLY CONNECTION

REQUIREMENTS

Unit TDB(C)-20 TDB(C)-40

230V - 1 Phase 33 Amps 57 Amps

400V - 3 Phase 33 Amps 57 Amps

Loading...

Loading...