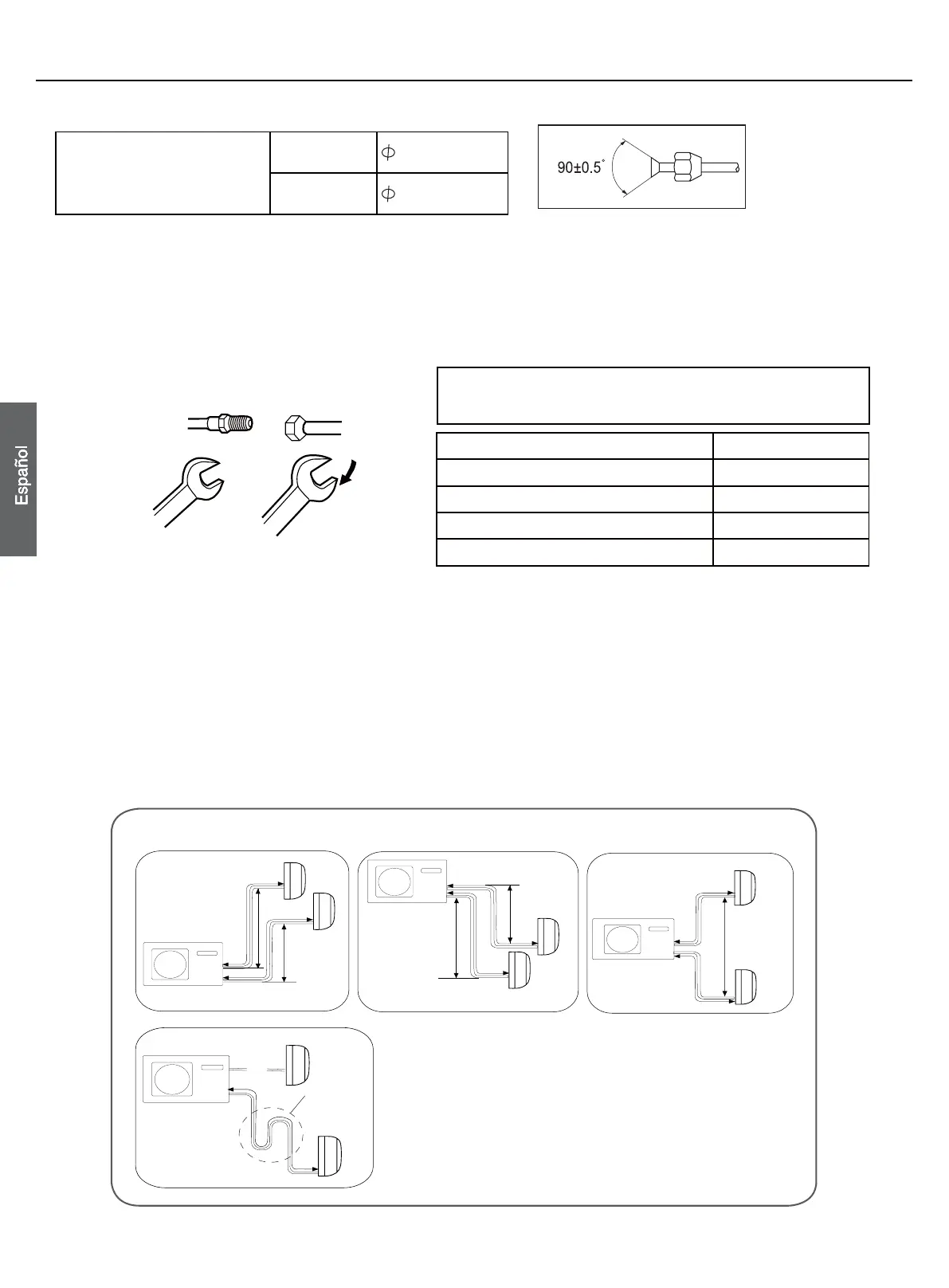

Ɣ Inserte las tuercas cónicas retiradas en los tubos que se

van a conectar y, a continuación, abocarde los tubos.

Si se fuerza la ¿MDFLyQ sin aplicar centrado podrían

dañarse los tubos y provocarse una fuga de gas.

Media unión Tuerca cónica

Llave Llave dinamométrica

Diámetro del tubo (ø) Par de apriete

Lado de líquido 6,35 mm (1/4") 18N.m

Lado de líquido/gas 9,52mm (3/8") 42 N.m

Lado de gas 12,7mm (1/2") 55 N.m

Lado de gas 15,88 mm (5/8") 60 N.m

Procedimiento instalación

Conexión de los tubos

1. Tamaño de los tubos

2U14CS2ERA

2U18FS2ERA

Tubo de líquido

6,35x0,8 mm

Tubo de gas

9,52x0,8 mm

2

. Conexión de los tubos

Ɣ Para doblar un tubo, intente hacer la curva lo más suave posible para no aplastar el tubo. El radio de

doblado

debe ser de entre 30 y 40 mm o superior.

Ɣ Será más sencillo conectar en primer lugar el tubo de gas.

Ɣ El tubo de conexión es especial para el tipo R410A.

Procure que no penetren materiales, como residuos de arena, agua, etc., en el tubo.

PRECAUCIÓN:

Procure que no penetren materiales, como residuos o arena, en el tubo. La longitud estándar del tubo es

de 5m. Si la longitud total del tubo es superior a 20m, se verá afectado el funcionamiento de la unidad, y

deberá cargarse el refrigerante a razón de 20 g/m. No obstante, la carga de refrigerante deberá ser

realizada por un ingeniero profesional en aire acondicionado. Antes de añadir refrigerante adicional,

realice una purga de aire desde los tubos refrigerantes y la unidad interior utilizando una bomba de vacío

y cargue después el refrigerante adicional.

B

A1

B1

A2

B2

B1

B2

A3

A1

B1

A2

B2

Unidad interior

Unidad exterior

Unidad interior

Filtro de

aceite

Ɣ Elevación máx. A1 máx =15 m A2 máx =15 m

A3 máx =15 m

Ɣ En caso de que la elevación A sea superior a 5 m, el ¿OWUR

de aceite debe instalarse cada 5 ~7 m.

Ɣ Longitud máx.: B1 máx. de 20m B2 máx. de 20m

(B1+B2) máx de 30m

Ɣ En caso de que la longitud total del tubo (B1+B2) sea

superior a 20 m, deberá cargarse el refrigerante a razón

de 20 g/m.

Unidad

interior

Unidad exterior

PRECAUCIÓN

Unidad interior

Unidad exterior

Unidad

interior

Unidad exterior

Unidad interior

Unidad

interior

24