USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

24

Two-Speed Pump

In a few cases the flow from a two-speed pump is below the minimum required to operate the water flow switch on the heater. In these cases the pump must

be run at high speed to operate the heater. If the pump and piping arrangement are such that the required minimum flow cannot be obtained, do not attempt

to operate the heater. Correct the installation.

NOTICE - Heater installation, checkout, and start-up should now be completed. BE SURE to leave this manual with the pool owner.

Maintenance & Service

PERIODIC INSPECTION: The heater is designed and built for long performance life when installed and operated according to the manufacturer’s directions.

Regular inspection by qualified service personnel is recommended to keep the heater working properly. The following inspection points are suggested to help

maximize heater life.

1. Periodically check the fan discharge area. The fan discharge must never be obstructed in any way and minimum clearances must be observed.

Remember that shrubs grow and in time may obstruct

2. Keep the entire pool heater area clean and free of all debris, corrosive materials, and other flammable vapors and liquids. Remove any leaves or

paper from around the heater.

3. Do not store chlorine, other pool chemicals, or other corrosives in the vicinity of the heater.

4. Do not use the heater if any part has been under water. Contact a qualified service technician to inspect the entire heater and replace any part of

the control system that was under water. If heater has been totally submerged in water it must be removed and the entire heater must be replaced.

5. An inspection program is a good preventative maintenance measure. Keep this manual in a safe place for future reference for yourself as well

as for a service technician to consult when inspecting or servicing the heater. Additional inspection procedures to be performed by a qualified

service technician.

Water Chemistry

WARNING - Water Chemistry. Failure to maintain proper water chemistry may cause premature heat exchanger damage or failure.

The heat exchanger in your pool heater is made from the highest quality of materials. The titanium condenser is a premium material and the processes used

to manufacture the heat exchanger are state of the art in pool heater design and manufacture. However, it remains vital that the heat exchanger be protected

from damaging or corrosive chemicals, insufficient water flow or improperly balanced water chemistry. Heat exchanger damage or failure resulting from im-

proper flow, improperly balanced pool water or the improper addition of sanitizer into the water is NOT covered under the terms of the warranty. The following

factors are critical to heat exchanger protection. Follow these guidelines to help prevent pre-mature damage or failure to your heater and heat exchanger.

1. WATER FLOW THROUGH HEATER Water must be flowing through the heater at the minimum rated flow rate during operation. Check that the pump

is operating and the system is filled with water and purged of all air prior to starting the heater. The minimum rated flow rates are listed in the

specifications section.

2. WATER CHEMISTRY: The chemistry balance and mineral content of swimming pool and spa water changes rapidly due to the addition of sanitizing

chemicals, user loads, exposed rain, runoff and the amount of sun - to name a few. Improper chemistry (See Table4) balance and mineral content

can cause scaling and deposits to form on pool walls, in the filtration system, in the heat exchanger tubes and additionally can promote corrosive

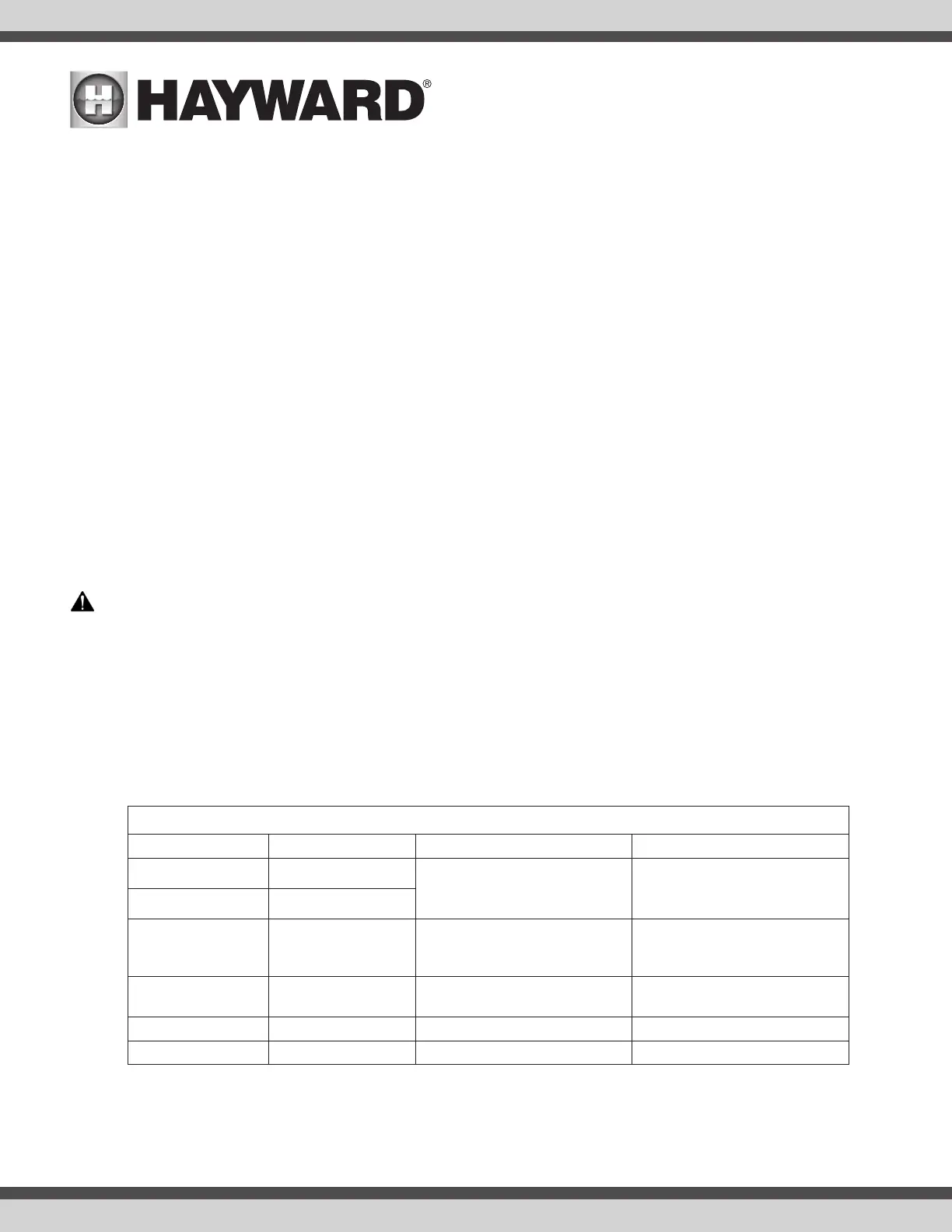

TABLE 4: Water Chemistry

Chemical Recommended Level Effect of Low Levels Effect of High Levels

Chlorine 1 - 3 ppm

hazy water, algae growth, bacteria

causing infections

swimmer irritation, bleaching of

clothes/hair, corrosive to heat

exchanger

Bromine 2 - 4 ppm

pH 7.4 - 7.6

corrosive to heat exchanger,

swimmer irritation

cloudy water, scaling of heat

exchanger, reduced sanitizer

effectiveness

Total Alkalinity 80 -120 ppm

corrosive to heat exchanger,

large fluctuations in pH

scaling of heat exchanger

Calcium Hardness 200 - 400 ppm corrosive to heat exchanger scaling of heat exchanger

Salt 2700 - 5000 ppm poor salt chlorinator performance corrosive to heat exchanger

Loading...

Loading...