4

English

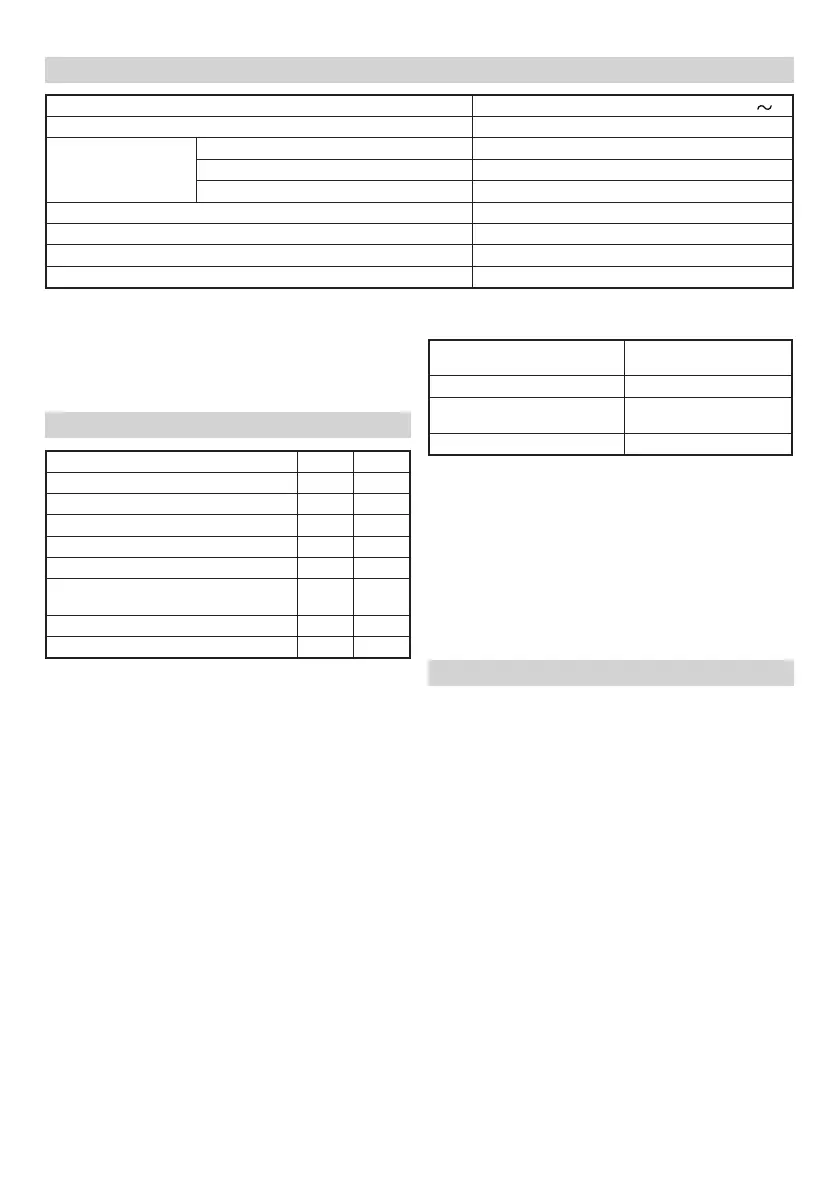

SPECIFICATIONS

Voltage (by areas)* (110 V, 120 V, 127 V, 220 V, 230 V, 240 V)

Power Input 400 W*

Cutting capacity

Mild Steel plate (400N / mm

2

) 1.6 mm

Stainless steel plate (600N / mm

2

) 1.2 mm

Aluminium plate (200N / mm

2

) 2.3 mm

Number of strokes at no load 2300 min

–1

Minimum cutting radius 40 mm

Width of nibbling groove 5 mm

Weight (without cord) 1.6 kg

* Be sure to check the nameplate on product as it is subject to change by areas.

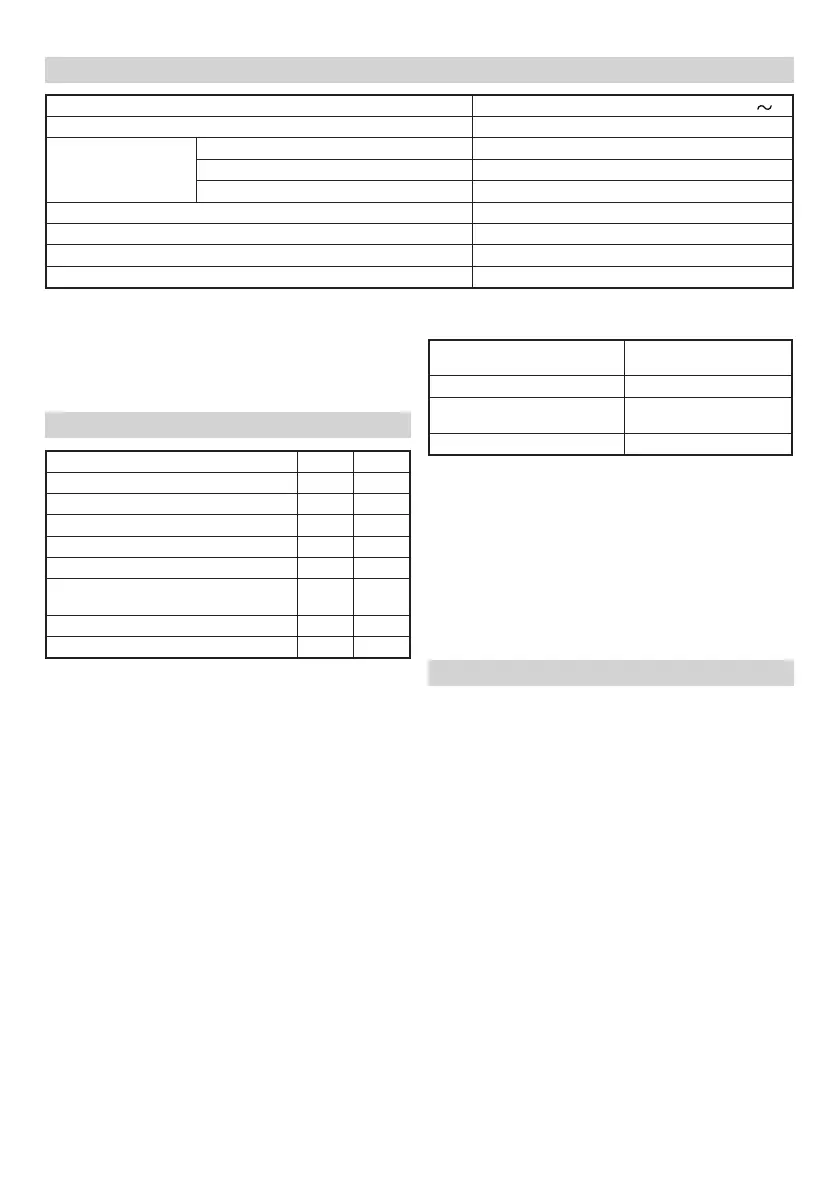

Cutting materials

Service life cutting

lengths of punch and die

1.6 mm Mild steel plates 300 m

1.6 mm Mild steel corrugated

and trapezoidal plates

50 m

1.2 mm stainless steel plates 200 m

When the machine is used according to the service

life indicated in the above table, the punch will have

abrasions as shown in the enlarged diagram of the

worn punch tip in Fig. 9. This is when the punch and die

should be replaced.

CAUTION

If the punch and die are used longer than the specifi ed

service life, the die holder will be subject to excessive

stress and may break off .

When a 1.6 mm mild steel trapezoidal plate is cut, wear

will be especially quick. Replace the punch and die as

soon as possible after reaching the service life.

MAINTENANCE AND INSPECTION

1. Checking punch and die

A worn or defective punch and die will greatly decrease

work effi ciency.

Check and replace them periodically. Refer to “Replacing

punch and die”.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws be

loose, retighten them immediately. Failure to do so could

result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the power

tool. Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Inspecting the carbon brushes (Fig. 7)

The motor employs carbon brushes which are

consumable parts. Since an excessively worn carbon

brush can result in motor trouble, replace the carbon

brushes with new ones having the same carbon brush

No. ⓙ shown in the fi gure when it becomes worn to or

near the “wear limit” ⓚ. In addition, always keep carbon

brushes clean and ensue that they slide freely within the

brush holders.

5. Replacing carbon brushes (Fig. 7)

Disassemble the brush cap with a screwdriver. The

carbon brush can then be easily removed.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifi cations herein are subject to

change without prior notice.

MOUNTING AND OPERATION

Action Figure Page

Replacing punch and die*

1

150

Switch operation 2 50

Cutting plates 3 51

Pocket cutting 4 51

Switch cutting direction 5 51

Cutting corrugated and trapezoidal

plates

652

Replacing carbon brushes 7 52

Selecting accessories ― 53

*1 Punch and die replacement (see Fig. 1)

CAUTION

During the following operations, use care to prevent dirt

adhering inside the gear cover ⓐ, inside the die holder

ⓑ and around the piston.

(1) Punch ⓒ replacement

(a) Loosen the M8 hexagon socket set screw ⓓ mounting

the die holder and remove the die holder.

(b) Loosen the M5 hexagon socket set screw ⓔ fastening

the punch to the piston ⓕ and pull out the punch.

(c) Insert the new punch while aligning the taper hole ⓖ of

the punch and the direction of the M5 hexagon socket

set screw, then securely tighten the hexagon socket set

screw.

(2) Die ⓗ replacement

Loosen the 2 machine screws ⓘ and replace the die.

(3) Lubricaton

When the above replacement operations are completed,

apply a suitable amount of machine oil to the sliding

surfaces around the punch and die and operate the

machine without a load.

Service Life of the Punch and Die

Wear and damage to the cutting edges of the punch and

die can greatly infl uence the cutting operation. Under

normal usage, the service life of the punch and die is

as shown in the table below. Replace the punch and die

promptly when the end of the service life approaches.

The punch and die should be replaced at the same time.

0000BookCN16SA.indb40000BookCN16SA.indb4 2014/12/2514:44:042014/12/2514:44:04

Loading...

Loading...