--- 2 ---

(1) Output section

The basic construction is the same as that of the Model NV 45AB except the 2-valve cylinder drive system that

is well reputed for quick driving is adopted.

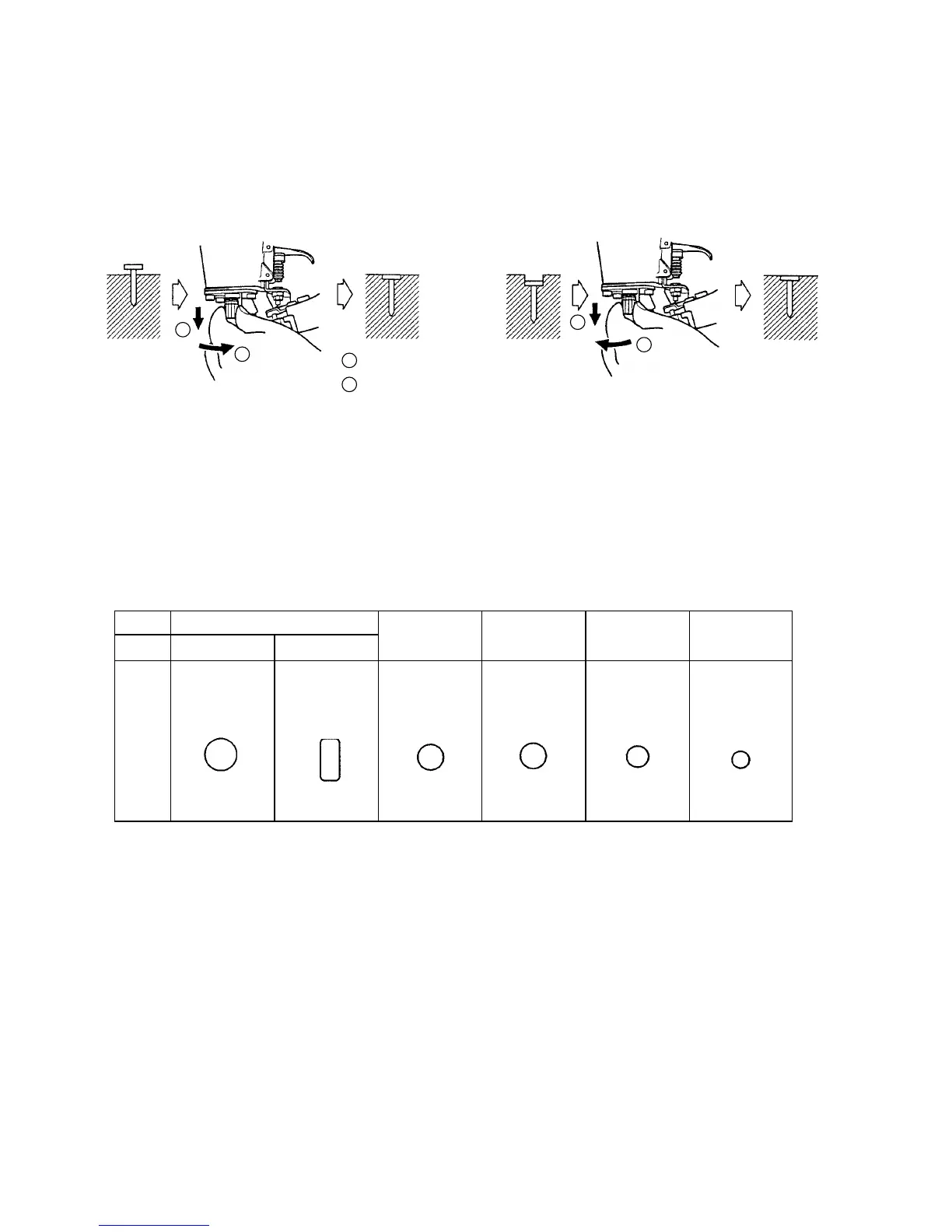

(2) Adjuster

While the Model NV 45AB requires a wrench to adjust the nailing depth, the Model NV 45AB2 requires no tool

for adjustment.

Turn the adjuster.

Pull the adjuster down.

(3) Magazine

While the Model NV 45AB is equipped with a bottom loading magazine, the Model NV 45AB2 is equipped with

a top loading magazine. The magazine can be opened/closed just by the nail guide operation. (The Model

NV 45AB requires operation of both the nail guide and the latch at the rear of the magazine.)

(4) Carbide chip

The carbide chips provided at the tip of the pushing lever are larger than the competitive products to prevent

wear .

Size of

carbide

chip

(area

ratio)

(5) Non-slip rubber

Although the Model NV 45AB is equipped with only a steel body guard at the side of the body, a non-slip

rubber is added to the Model NV 45AB2.

(6) Handle grip

Thanks to the adoption of the grip rubber that is common to the Model NR 90AC2, the handle grip of the

Model NV 45AB2 is more durable than that of the Model NV 45AB.

Model

HITACHI

PQRS

NV 45AB2 NV 45AB

7.5 mm dia.

(1)

5 mm dia.

(0.4)

6 mm dia.

(0.6)

6 mm dia.

(0.6)

4.5 mm x 10 mm

(1)

4 mm dia.

(0.3)

Maker

1

2

Too shallow

Flush Too deep

1

2

2

1

Flush