©2018 American Honda Motor Co., Inc. Page 3 of 6

5. INSPECTION

Perform a visual inspection of the GCU and inverter. Component inspection is listed in the order in which they need to

be removed to access the next component.

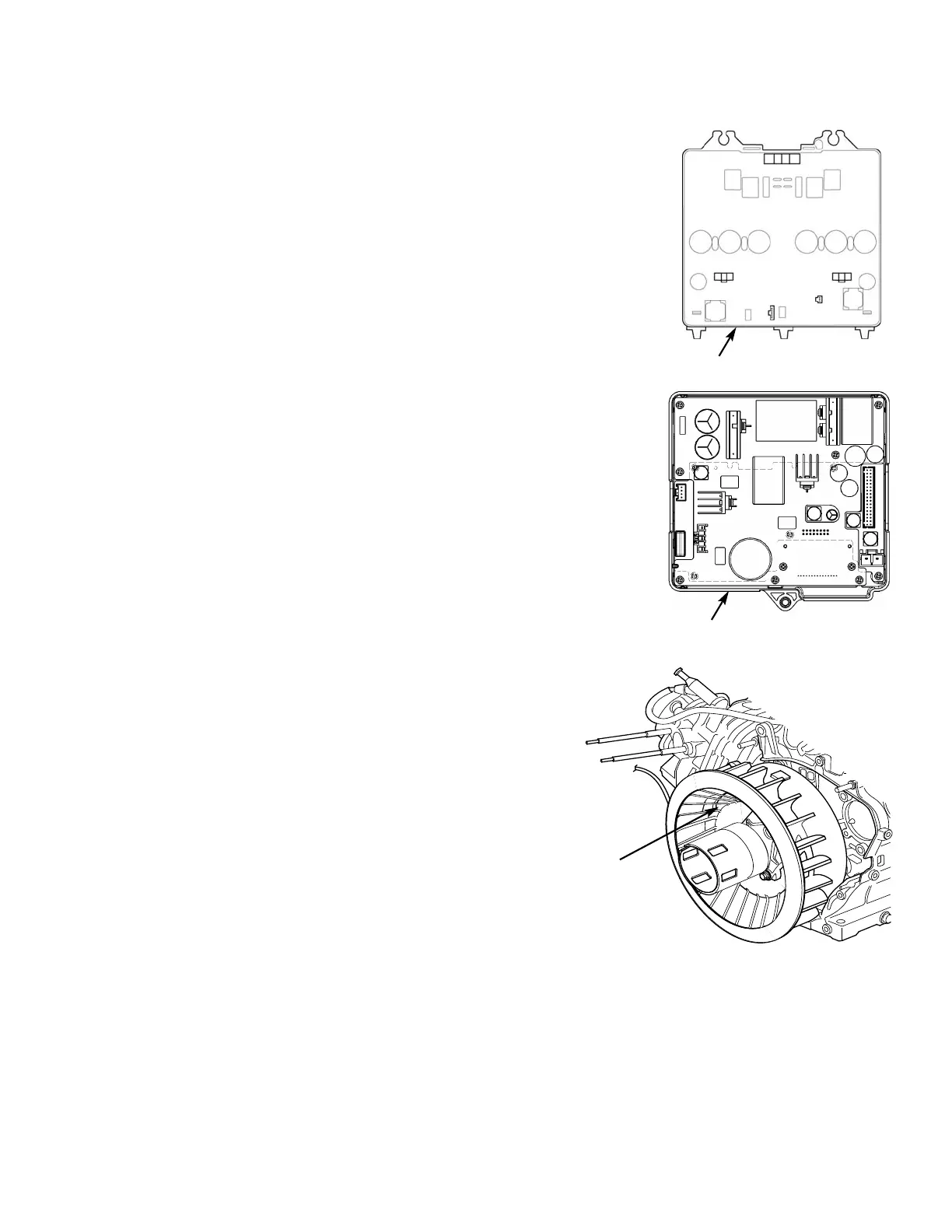

Inverter: To visually inspect the inverter, remove the front cover and the control

panel. Visually inspect the back of the inverter for any discolored or damaged wiring,

capacitors, or connectors, and note any bubbling, corrosion, or other unusual

conditions. If any of these issues are present, the inverter is likely faulty.

While the inverter may be faulty, it may not be the cause for the overall generator

failure. Some other circumstance, or other component failure, may have caused the

inverter to fail. Test the stator (see below) before contacting Techline or your DSM

for further instruction.

GCU: With the front cover and the control panel removed, visually inspect the circuit

board on the backside of the GCU for any discolored spots, deterioration,

contamination, or deformed capacitors.

Stator: The output and resistance tests performed in the

Generator Troubleshooting Guide or the appropriate shop manual

should be enough to determine if the stator is good or not. The

stator resistance readings should be consistent. If there is more

than 0.2 Ω of difference between readings, the stator has failed.

To visually inspect the stator, remove the spark plug, inverter, and

recoil starter, and then rotate the cooling fan until you can look

through the rotor windows at the stator windings. Rotate the rotor

by hand and slowly look for any signs of overheated or discolored

stator windings.

INVERTER

GCU

ROTOR

WINDOW