65-0156—1 6

C7024E,F

INSTALLATION

Fig. 4—Example of flame discrimination

problem (opposed burners).

M1957

DETECTOR A

FLAME A

DETECTOR B

FLAME B

Sight pipes with diameters 2 to 3 in. [51 to 76 mm]

pro-duce better results for horizontal rotary burners,

which require wide viewing angles. A wide viewing

angle can also be obtained by using a short sight pipe.

Prepare Hole in Wall of Combustion Chamber

At the selected location, cut or drill a hole the proper

diameter for the sight pipe into the wall of the combustion

chamber. Flare the hole to leave room for small adjust-

ments of the sighting angle. The taper of the hole should be

about 1 in. for every 3 in. [25 mm for every 76 mm] of wall

thickness.

Mount Sighting Pipe

Thread one end of the pipe to fit the mounting flange,

union, or required coupling. Cut the pipe to the desired

length (as short as practicable) and at an angle so it fits

flush with the wall of the combustion chamber. Tack

weld the pipe to the wall in a trial position. Do not weld

the sighting pipe permanently in place until after com-

pleting the Adjustments and Checkout section.

NOTE: If you use part no. 118367A Swivel Mount and

you are positive about the location and sighting angle,

permanently weld the pipe.

Install Fittings

In some cases, the sight pipe will not directly fit the

C7024 Mounting Flange or union. Also, it may be desir-

able or necessary to vent the sight pipe. You may also

want to use a swivel mount or an antivibration mount.

Each of these cases may require additional fittings.

Reducer

For sight pipes of larger diameter than the mounting

flange connector or union, install a reducer as illustrated

in Fig. 5. The reducer will require a close nipple with

these external threads:

C7024E: 3/4 in. NPT.

C7024F: 1 in. NPT.

Fig. 5—Typical mounting of C7024.

1

CLOSE NIPPLE

(3/4 in. FOR

A C7024E; 1 in.

FOR A C7024F.

TEMPORARY

TACK WELD

COMBUSTION

CHAMBER WALL

REDUCER

BLACK IRON SIGHT

PIPE (1-1/2 TO 3 in.

[38 TO 76 mm] DIA.)

REFRACTORY

FLARED

HOLE

1

IF VENTILATION OF THE SIGHTING PIPE IS REQUIRED, ADD PIPE

TEE, PERFORATED NIPPLE, OR OTHER SUITABLE DEVICE

FOR VENTILATION.

M1958A

SIGHT PIPE VENTILATION

It may be necessary to ventilate the sight pipe to cool

the detector or to clear a viewing path through UV

radiation attenuating material.

For a negative pressure combustion chamber, drilling

a few holes in the section of the sight pipe outside the

combustion chamber will allow air at atmospheric pres-

sure to flow through the sight pipe into the chamber. A

perforated pipe nipple between the sight pipe and the

detector can also be used.

For a positive pressure combustion chamber, connect

a supply of pressurized air from the burner blower to

flow supply through the sight pipe into the chamber. The

air pressure must be greater than the chamber pressure.

SWIVEL MOUNT

To facilitate proper flame sighting, part no. 118367A

Swivel Mount is available. The swivel mount will re-

quire a reducer of the proper size to mount it onto the

sight pipe. It will also require a one-inch close nipple for

mounting to a C7024 with a one-inch connector. For

mounting details for the 118367A Swivel Mount, refer

to form 60-0361.

ANTIVIBRATION MOUNT (C7024E)

The detector will withstand normal burner vibra-

tion. If the vibration is excessive, part no. 123539

Antivibration Mount is available for the C7024E. (For

mounting details, see form 60-0361.) If you use this

mount, install it before positioning and sighting the

detector.

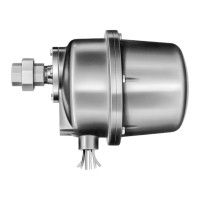

MOUNT THE DETECTOR

Mount the detector on the sight pipe, reducer, or other

fitting (see Figs. 6 to 9).

The C7024E,F Self-Checking Flame Detectors incor-

porate an oscillating shutter mechanism and therefore

require special consideration for mounting positions other

than vertically sighting downward or upward as illus-

trated in Fig. 6.