Appendix

9

10. Appendix

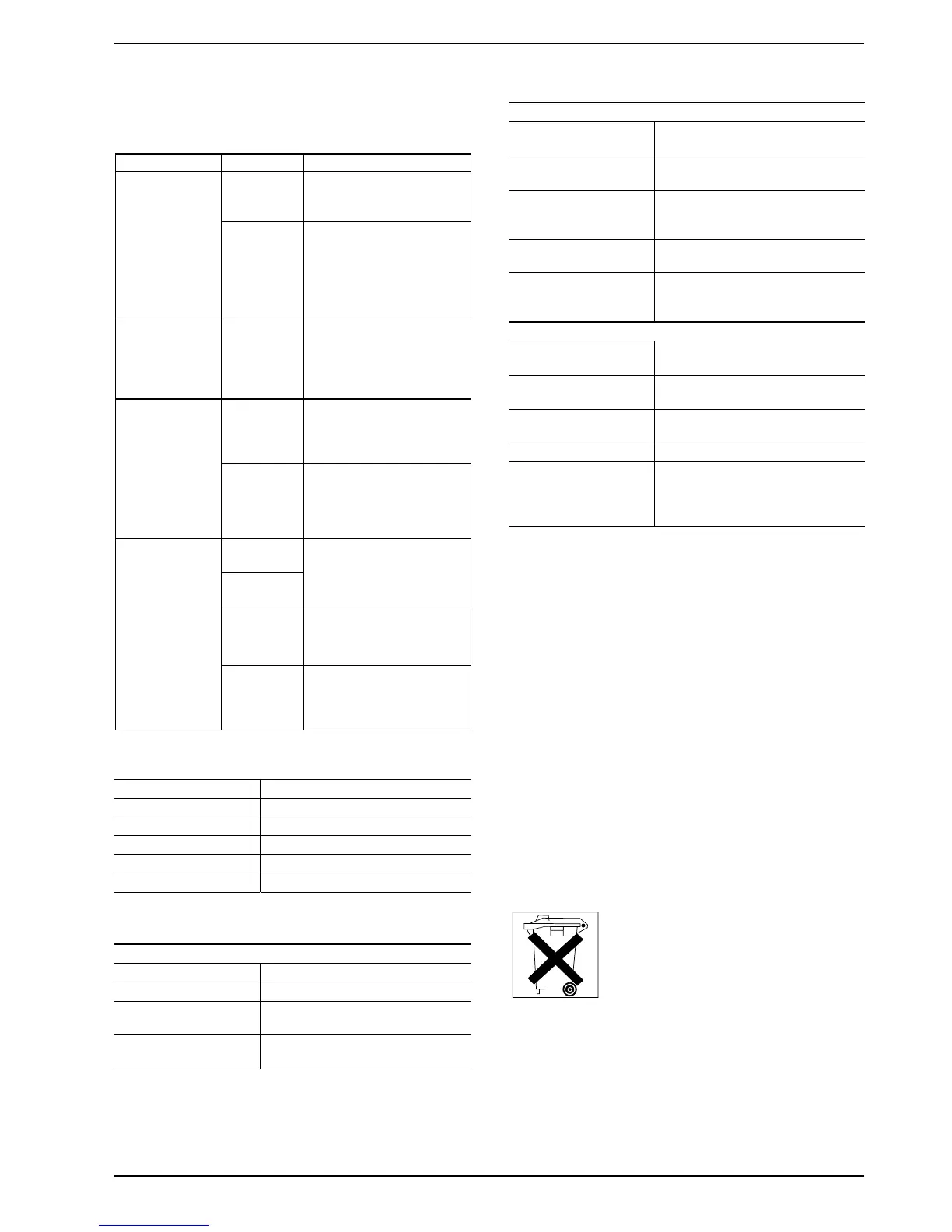

10.1. Help with problems

Problem Cause Remedy

Batteries

inserted

incorrectly

► Insert the batteries

correctly.

Teach-in failed

Radio

connection

failure

► Eliminate interference

sources (metal, wireless

devices).

► Correct installation site.

► Repeat the teach-in.

HC60NG does

not react to set

point changes

on HCW 80

HC60NG

and HCW

80 not

teached-in

► Reset HC60NG.

► Follow the teach-in

procedure as described

in section “5”.

Teach-in

procedure

incorrect/

incomplete

► Repeat the teach-in.

After teach-in

red LED is on

and green LED

is flashing once

every 3 sec

Position of

HCW 80

incorrect

► Repeat the teach-in

keeping approx. 1 m

distance between HCW

80 and

HC60NG.

Communi-

cation loss

RF signal

blocked

► Relocate the HCW 80

(see section “3.2”).

Batteries of

HCW 80

exhausted

► Replace batteries in

HCW 80

(see section “9”).

Red LED of the

HC60NG is on

HC60NG

and

HCW 80 not

teached-in

► Follow the teach-in

procedure as described

in section “5”.

10.2. Specifications HCW 80

Batteries 1.5 V, type LR06, AA

Frequency 868.3 MHz (transmitter)

Operating temperature 0 °C to 50 °C

Storage temperature –20 °C to 70 °C

Humidity 5 % to 90 % relative humidity

IP class 30

10.3. Specifications HC60NG

Electrical

Receiver power supply 230 V AC (+10 %, –15 %), 50 Hz

Switch type SPDT potential free

Output rating 24-230 V AC, 10 A resistive,

3 A inductive, 0.6 p.f.

Wire access

(receiver only)

From the rear (wall box mounting),

right an bottom

RF

RF operation band ISM (868.0-868.6) MHz,

1 % duty cycle

RF communication

range

30 m in a residential building

environment

RF communication

technology

Short, high rate transmissions to

minimise air time and avoid

collisions

Blocking immunity Receiver class 2 (ETSI EN300

220-1 version 1.3.1)

RF binding method Factory pre-bound with the room

unit HCW 80 (kit Y6630D1007

only)

Environmental & Standard

Operating temperature 0 to 40 °C when relay load <8 A

0 to 30 °C when relay load >8 A

Shipping & storage

temperature

–20 to 55 °C

Humidity Humidity range 0 to 90 % rh,

non-condensing

IP class 30

Meeting the following

standards

EN 60730-1 (1995), EN 55014-1

(1997), EN 55014-2 (1996), ETSI

EN 300 220-3 (2000), ETSI

EN 301 489-3 (2000)

10.4. Device and function definition in

accordance with EN 60730-1

· Purpose of the device is temperature controlling

· Device fulfills protection class 2

· Independently installable electronic control system

with fixed installation

· Type of action is type 1.8

· Temperature of ball thrust hardness test for

housing components 75 °C and for live parts such

as, for example, terminals 125 °C

· EMC emitted interference test at 230 V~, 50 HZ

maximum

· Pollution severity is 2

· Rated voltage is 4000 V (corresponding to

overvoltage category III)

· Software class is A

10.5. WEEE directive 2002/96/EC – Waste

Electrical and Electronic Equipment

directive

► At the end of the product life dispose of

the packaging and product in a

corresponding recycling centre.

► Do not dispose of the unit with the usual

domestic refuse.

► Do not burn the product.

Loading...

Loading...